Solar energy light condensation structure

A solar concentrator and heat collector technology, applied in the field of solar energy utilization, can solve problems such as light pollution and heat loss, and achieve the effects of reducing heat loss, uniform heating, and restraining air flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

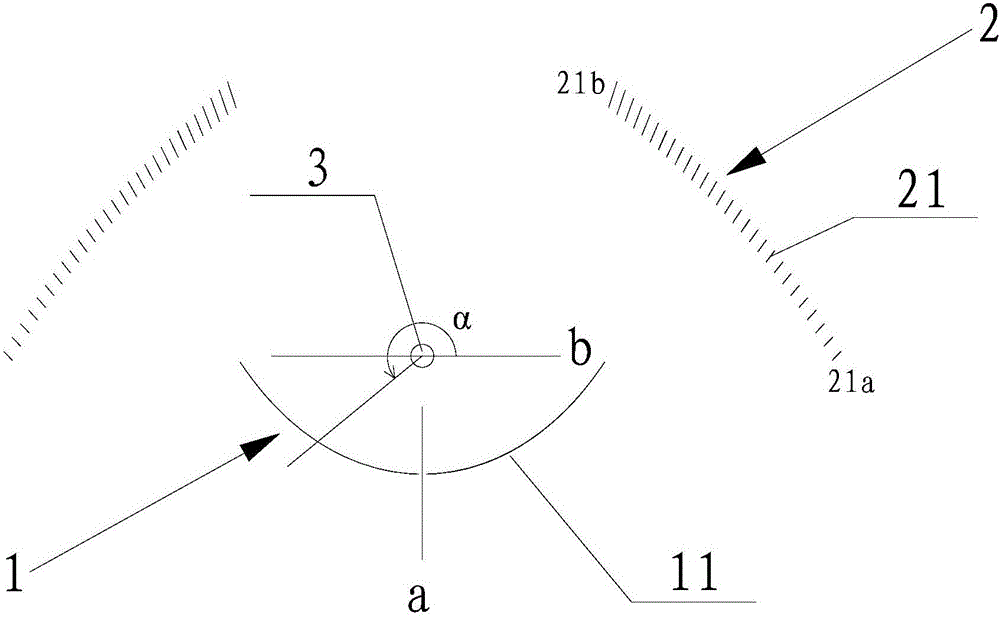

[0017] Such as figure 1 The solar concentrating structure shown is a linear concentrating structure, which mainly includes three parts: a first reflector 1 , a Fresnel reflector group 2 and a heat collector 3 .

[0018] Wherein, the heat collector 3 is arranged at the focal point of the first reflector 1, and the sunlight can be focused to the lower surface of the heat collector 3 by the first reflector 1 (the definition of the relevant direction here is according to figure 1 The direction in is defined, the same below). There is at least one group of Fresnel reflector groups 2 , which are arranged on the other side of the heat collector 3 (that is, above the first reflector 1 ), and are used to focus sunlight onto the surface of the heat collector 3 . Each group of Fresnel reflector groups 2 is formed by arranging a plurality of reflectors 21 with different angles in turn, and the symmetry plane passing through the heat collector 3 in the first reflector 1 is defined as its ...

Embodiment 2

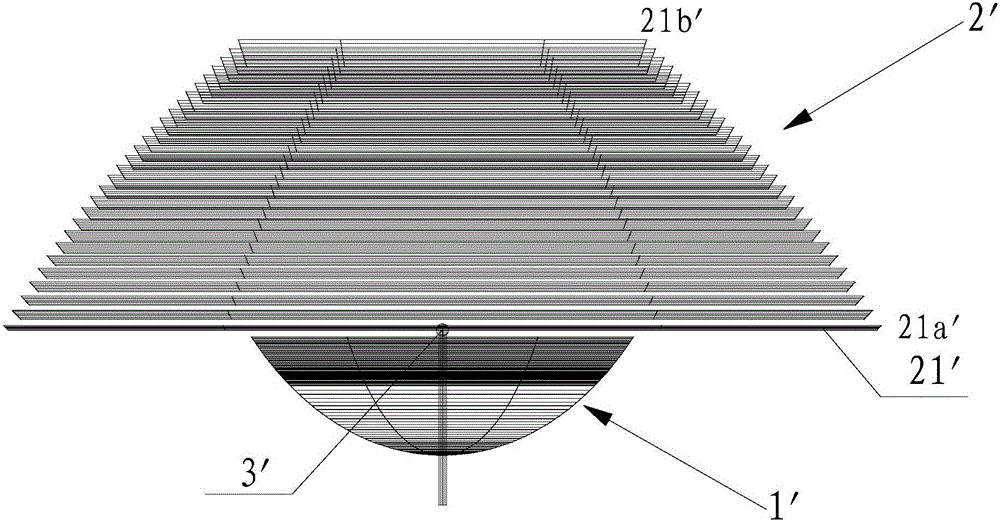

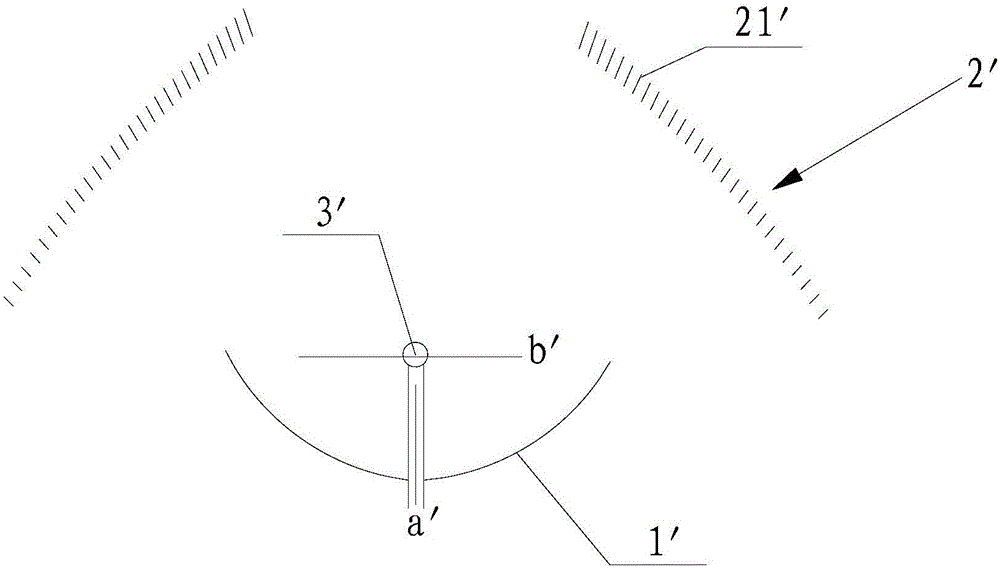

[0022] Such as figure 2 and image 3 The solar concentrating structure shown is a point concentrating structure, and mainly includes three parts: the first reflector 1', the Fresnel reflector group 2' and the heat collector 3', and its specific structure and embodiment The structure in 1 is basically similar, the difference is that: the first reflector 1' is a spherical mirror; the Fresnel reflector group 2' is a group, which consists of a plurality of concentrically arranged annular reflectors 21' arranged sequentially from bottom to top. become.

[0023] In this embodiment, the radius of the heat collecting surface of the first reflecting mirror 1' can be 2025mm (here, the size of the solar concentrating structure is just an example, and its specific size can be scaled); the heat collector 3' is a Stirling machine Advanced heat collection system, the heat collection tube adopts a spherical double helix structure to increase the heating area. Similarly, the sunlight withi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap