Biomass circulating fluidized bed boiler slagging device

A circulating fluidized bed and biomass technology, which is applied in the direction of fluidized bed combustion equipment, fuel burned in molten state, combustion type, etc., can solve problems such as poor fuel adaptability, poor slag discharge, and failure to discharge impurities in biomass , to achieve the effects of reducing emission concentration, reducing energy loss, and reducing pressure head wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings.

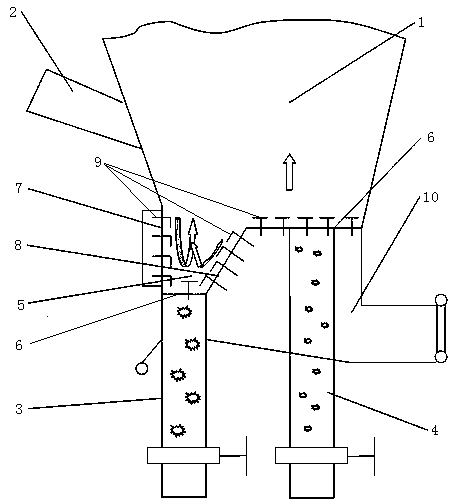

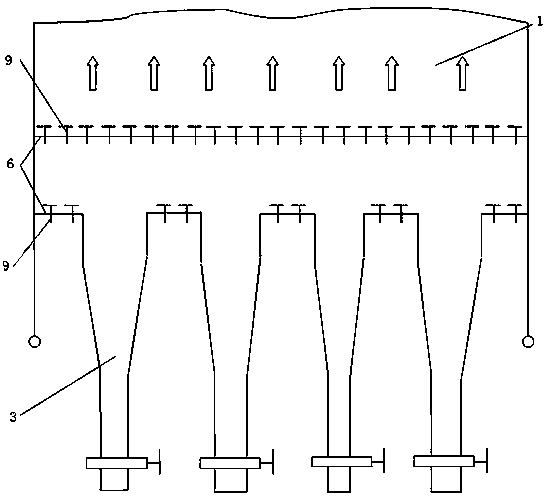

[0022] Such as Figure 1-2 As shown, the biomass circulating fluidized bed boiler slagging device provided in this embodiment includes a combustion chamber 1, a furnace feeding device 2 is connected above the combustion chamber 1, and a large slag is provided below the combustion chamber 1. The slag discharge pipe 3 and the crushed slag discharge pipe 4, one side of the bottom of the combustion chamber 1 is a horizontal plate, and the other side is a single V-shaped screening bucket 5, and the single V-shaped screening bucket 5 is located obliquely below the horizontal plate , the single V-shaped screening bucket 5 includes a vertical part, a horizontal part and an inclined part connected in sequence, the other end of the inclined part is connected with the horizontal plate, the large slag discharge pipe 3 communicates with the horizontal part, and the broken slag discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com