Offshore LNG receiving system and method

A receiving system and connecting system technology, applied in the field of offshore and offshore LNG receiving systems, can solve the problems of high terminal operation cost, difficult terminal site selection, large storage capacity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

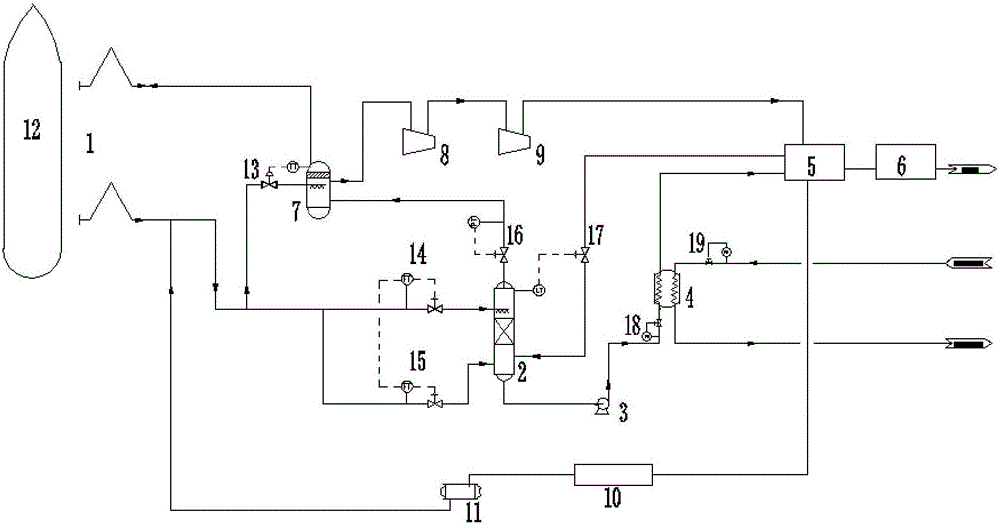

[0023] An off-shore LNG receiving system, such as figure 1 As shown, it includes: LNG receiving device 1, recondenser 2, booster pump 3, LNG vaporizer 4, pressure regulating and metering device 5, ship-shore connection system 6, BOG separation tank 7, primary compressor 8, Secondary compressor 9, small liquefaction device 10, LNG storage tank 11 for cold preservation cycle, fully cooled LNG carrier 12, and various valves 13-19 (including FV valves 14, 15, 18, 19, PV valve 16, LV valve 17 , TV valve 13), FV valve refers to flow interlock control valve, PV valve refers to pressure interlock control valve, LV valve refers to liquid level interlock control valve, TV valve refers to temperature interlock control valve. The offshore and offshore LNG receiving system is set on a ship or an offshore device, and the heat balance during system operation is regulated by an external hot water / sea water system.

[0024] in:

[0025] The LNG receiving device 1 is composed of the LNG loadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com