A double-pit combustor structure for a rotary engine

A rotary engine, double-pit type technology, used in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problem of not organizing a variety of airflow motion forms, reducing ignition reliability at the rear of the combustion chamber, and unfavorable oil and gas mixing. and ignition problems, so as to optimize the distribution law of the in-cylinder flow field, optimize the distribution law, and achieve the effect of stratification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

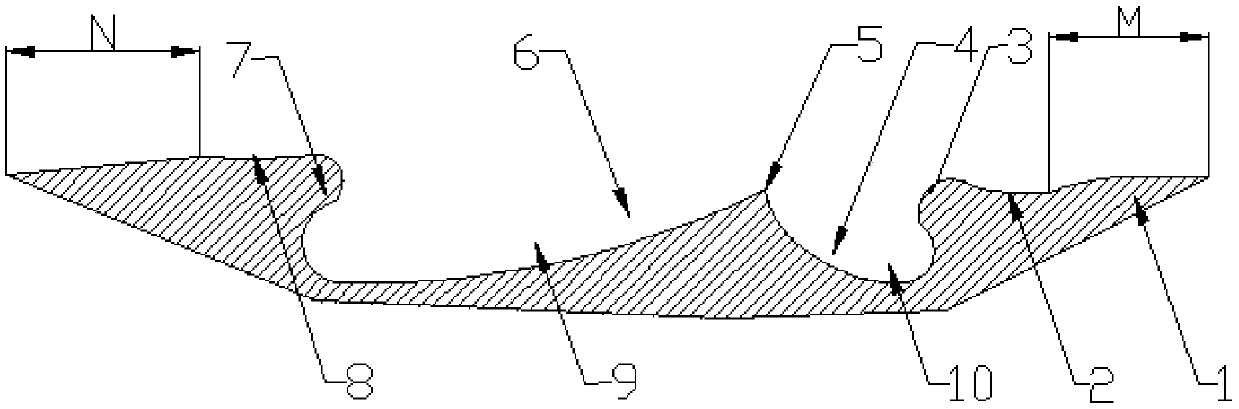

[0021] Such as figure 1 As shown, the double-pit type combustion chamber for the rotary engine according to the present invention includes: the front transition arc 2, the front neck 3, the front guide wall 4, the middle inclined guide table 5, and the rear guide wall 6 , Rear necking 7, Rear transition arc 8. The rear dimple 9 is composed of a rear guide wall 6 and a rear constriction 7 , and the front dimple 10 is composed of a front constriction 3 and a front guide wall 4 .

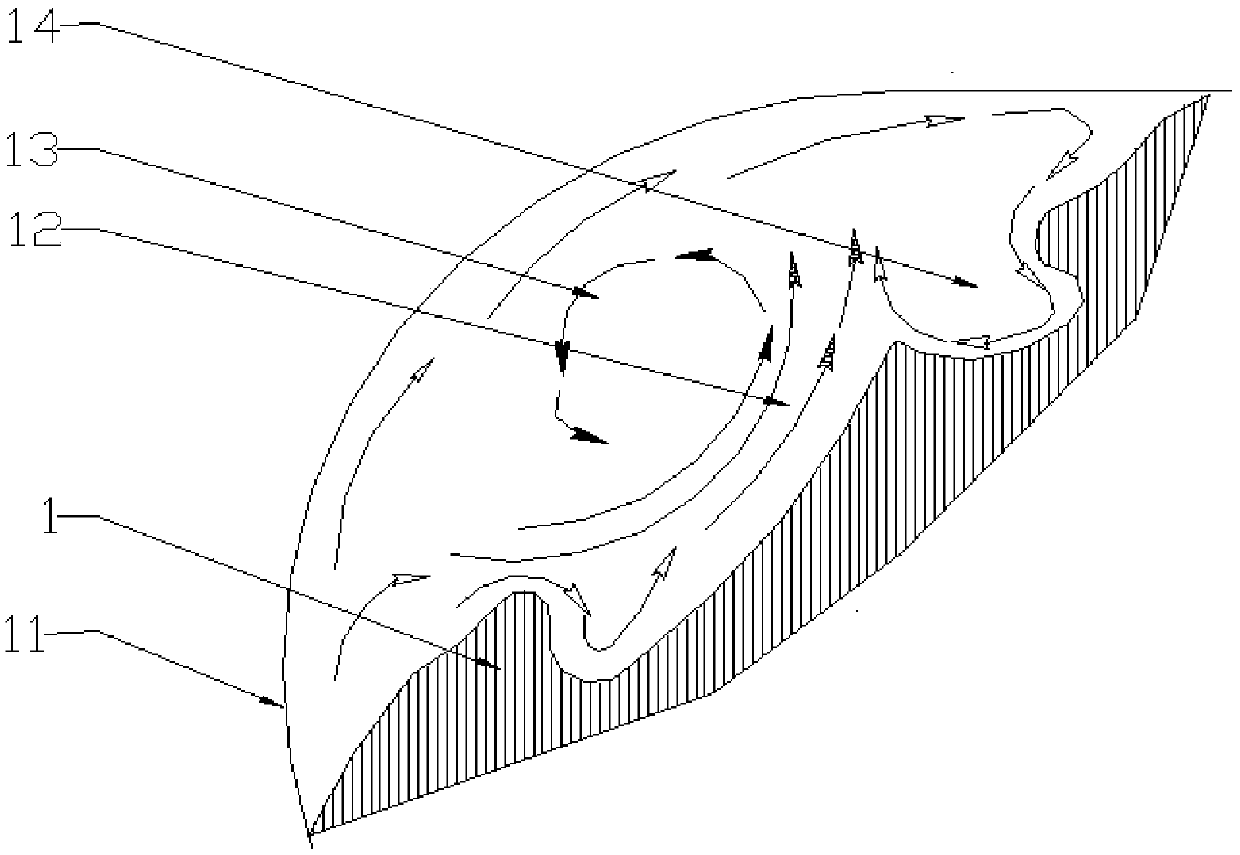

[0022] Such as figure 2 As shown, in the compression stroke of the rotary engine, combined with the intake inertia, under the guidance of the front shrinkage 3 and the front guide wall 4, a compression front vortex 14 is generated in the front dimple 10, and the rear guide wall 6 and Under the guidance of the rear constriction 7, a post-compression vortex 13 is generated in the rear dimple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com