Feeding device for underground coal mine long-distance guniting system

A feeding device and long-distance technology, applied in shaft equipment, shaft lining, underground chambers, etc., can solve problems such as low production efficiency, blocked pipes, shotcrete machine relocation, and difficult material transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings (hereinafter, the running direction of the material is used as the front description).

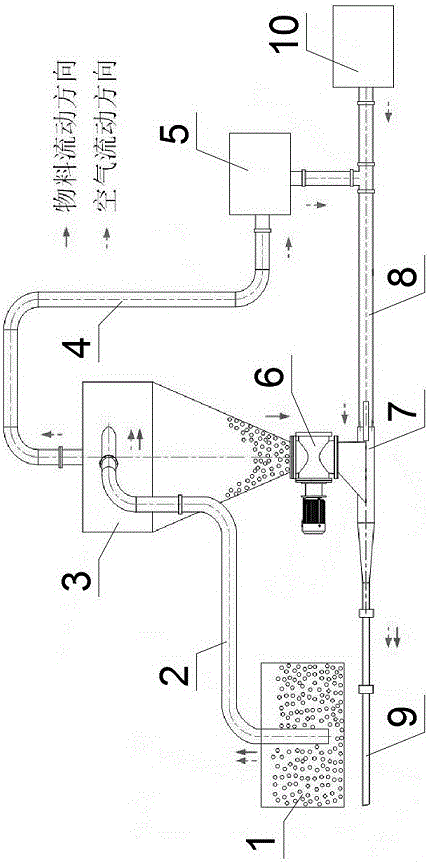

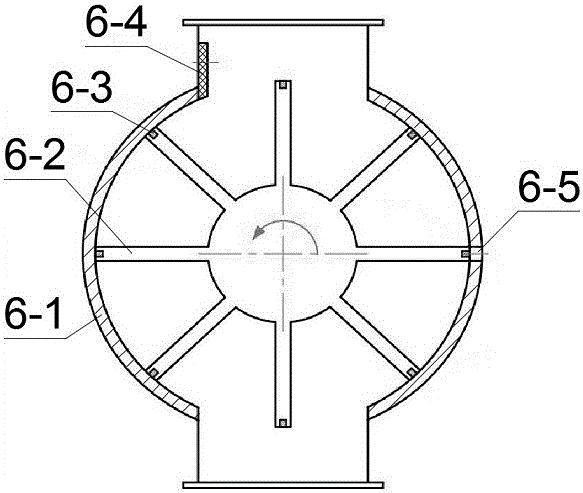

[0027] like figure 1 As shown, the feeding device of the long-distance shotcrete system in the coal mine includes a mixing bin 1, a material suction pipe 2, a cyclone collector 3, a cyclone outlet pipe 4, a vacuum pump 5, a shut-off fan 6, an injector 7, and an injector Air inlet pipeline 8, long-distance material delivery pipeline 9 and main air source air compressor 10.

[0028] The mixing silo 1 is set near the rails of the roadway and includes a mixing mechanism.

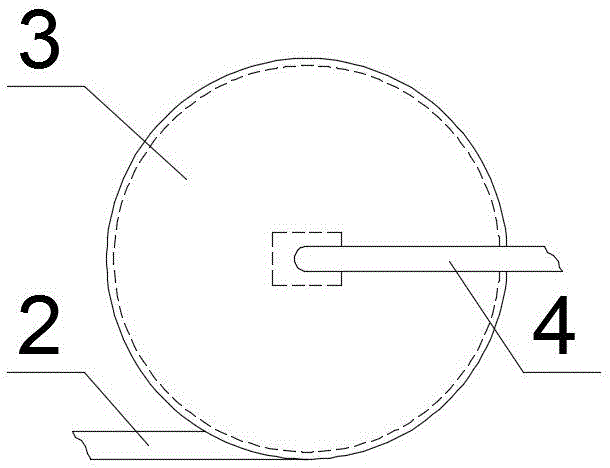

[0029] like figure 2 As shown, one end of the suction pipe 2 extends into the bottom of the mixing bin 1, and the other end communicates with the upper part of the cyclone collector 3 along the tangential direction of the cylinder of the cyclone collector 3.

[0030] Described cyclone collector 3 is the airtight con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com