Recoverable assembling framework and sawtooth anchor rod structure and construction method

A technology of anchor rods and frames, applied in excavation, foundation structure engineering, sheet pile walls, etc., can solve the problems of long construction period, surrounding underground environmental pollution, environmental pollution, etc., and achieve high reuse rate, high degree of assembly, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, and the given examples are only used to explain the present invention, and are not intended to limit the present invention. Within the principle of the present invention, the modifications, equivalent replacements and improvements all belong to the protection scope of the present invention.

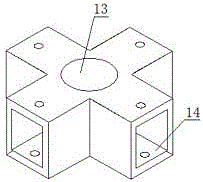

[0019] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8 and 9, the present invention provides a recyclable assembled frame sawtooth anchor, comprising a frame 1, an anchor 2 and an anchor 3; the frame 1 consists of a square tube 4, a sleeve The tube 5 and the cross 6 are connected, the square tube 4 extends into the sleeve 5 and is connected by bolts to form a beam and a column, the beam and the column are respectively inserted into the cross 6, and the surrounding bolts are fixed; Sheet 9 and shaft 10, the steel pipe 7 is provided with a chute 17, the first positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com