Preparation of a novel organic / inorganic composite sizing system

A new type of surface sizing technology, applied in the direction of inorganic compound addition, no pigment coating, water repellent addition, etc., can solve the problems of environmental pollution and hazards of operators, affect the strength of paper, and high cost, and achieve the goal of reducing environmental pollution Risk, low cost, and the effect of a clean papermaking system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

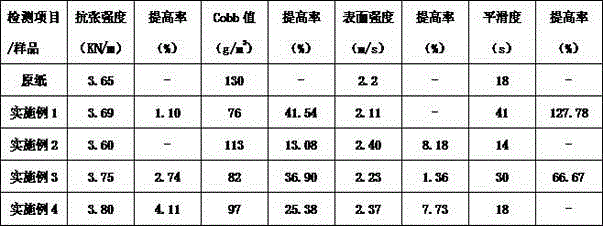

Examples

Embodiment 1

[0021] Degradation of chitosan: dissolving chitosan in an Erlenmeyer flask with 4% acetic acid by mass fraction, completely dissolving chitosan at a temperature of 60°C, adding 4% H2O2 dropwise at a constant speed while stirring, The rotation speed was 150 r / min, and the reaction was kept for 4 h, then 2 mol / L NaOH solution was added to the reaction solution, neutralized to neutral (pH = 7), left overnight, filtered with suction, and the volume ratio was added to the filtrate 3:1 95% ethanol-water solution, let stand for 1 h to settle, centrifuge out the degradation products, wash with ethanol and vacuum dry.

[0022] Preparation of silica sol: Add a certain amount of deionized water into the three-necked flask, raise the temperature to 70 °C, add 1 / 3 of the weighed silicon powder mass and 1 / 3 of the weighed sodium hydroxide mass to the three-necked flask , keep the reaction for 1 h. Then the temperature was raised to 75 °C, and then 1 / 3 of silicon powder and 1 / 3 of sodium hy...

Embodiment 2

[0026] Degradation of chitosan: dissolving chitosan in a conical flask with 4% acetic acid by mass fraction, dissolving chitosan completely at 60°C, adding 2% H2O2 dropwise at a constant speed while stirring, The rotation speed was 150 r / min, and the reaction was kept for 4 h, then 2 mol / L NaOH solution was added to the reaction solution, neutralized to neutral (pH = 7), left overnight, filtered with suction, and the volume ratio was added to the filtrate 3:1 95% ethanol-water solution, let stand for 1 h to settle, centrifuge out the degradation products, wash with ethanol and vacuum dry.

[0027] Prepare silica sol: add 30 nm silica sol in 200 mL deionized water as a seed solution, control the concentration at 1.0%, add 15 g silica powder and 0.3 g sodium hydroxide in batches, react at 90 °C for 8 h, The prepared silica sol has a particle size of 50 nm.

[0028] Preparation of compound sizing system: Degraded chitosan is made into an aqueous solution with a mass fraction of ...

Embodiment 3

[0031]Degradation of chitosan: dissolving chitosan in an Erlenmeyer flask with 4% acetic acid by mass fraction, fully dissolving chitosan at a temperature of 50°C, adding H2O2 with a mass fraction of 43% at a constant speed while stirring, The rotation speed was 150 r / min, and the reaction was kept for 4 h, then 2 mol / L NaOH solution was added to the reaction solution, neutralized to neutral (pH = 7), left overnight, filtered with suction, and the volume ratio was added to the filtrate 3:1 95% ethanol-water solution, let stand for 1 h to settle, centrifuge out the degradation products, wash with ethanol and vacuum dry.

[0032] Prepare silica sol: add 30 nm silica sol in 200 mL deionized water as a seed solution, control the concentration at 1.5%, add 15 g silica powder and 0.3 g sodium hydroxide in batches, and react at a temperature of 90 °C for 8 h. Prepare silica sol.

[0033] Preparation of compound sizing system: degraded chitosan was made into a 30% aqueous solution wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com