Textile penetrant and preparation method thereof

A penetrant and textile technology, applied in textiles and papermaking, chemical instruments and methods, fiber processing, etc., can solve the problems of long process route, large equipment occupation, large energy consumption, etc., to reduce environmental pollution and low CMC value. , good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

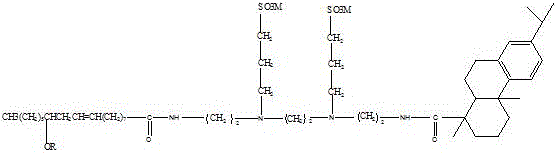

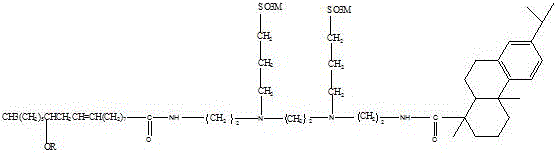

Image

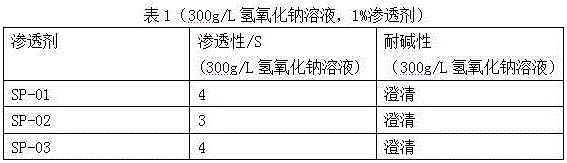

Examples

Embodiment 1

[0017] A preparation method of unsymmetrical bisamide sulfonic acid phosphate, comprising the following steps:

[0018] 1. Add 1.0 mol ricinoleic acid and catalyst potassium hydroxide (according to 1.5% of the mass of ricinoleic acid) into the reactor equipped with condenser, thermometer and stirrer, start stirring, and raise the temperature to 90°C under the protection of nitrogen. Slowly add 1.1mol triethylenetetramine dropwise to the reactor, and the dropwise addition is completed within 1 hour, then react at a constant temperature of 150-160°C for 6 hours, cool to room temperature, and obtain an intermediate monoamide, and then add 1mol dehydroabietic acid, start stirring, heat up to 90°C under nitrogen protection, then react at a constant temperature of 150-160°C for 6h, cool to room temperature, use 150# solvent oil and butanone mixed solvent (volume ratio 1:1) Recrystallize 3 times, remove by-products, dry in a vacuum drying oven at 60°C to constant weight, and obtain a...

Embodiment 2

[0022] A preparation method of unsymmetrical bisamide sulfonic acid phosphate, comprising the following steps:

[0023] 1. Add 1.0 mol ricinoleic acid and catalyst potassium hydroxide (according to 1.5% of the mass of ricinoleic acid) into the reactor equipped with condenser, thermometer and stirrer, start stirring, and raise the temperature to 90°C under the protection of nitrogen. Slowly add 1.1mol triethylenetetramine dropwise to the reactor, and the dropwise addition is completed within 1 hour, then react at a constant temperature of 150-160°C for 6 hours, cool to room temperature, and obtain an intermediate monoamide, and then add 1mol dehydroabietic acid, start stirring, heat up to 90°C under nitrogen protection, then react at a constant temperature of 150-160°C for 6h, cool to room temperature, use 150# solvent oil and butanone mixed solvent (volume ratio 1:1) Recrystallize 3 times, remove by-products, dry in a vacuum drying oven at 60°C to constant weight, and obtain a...

Embodiment 3

[0027] A kind of preparation method of unsymmetrical bisamide sulfonic acid phosphate ester salt, comprises the following steps:

[0028] 1. Add 1.0 mol ricinoleic acid and catalyst potassium hydroxide (according to 1.5% of the mass of ricinoleic acid) into the reactor equipped with condenser, thermometer and stirrer, start stirring, and raise the temperature to 90°C under the protection of nitrogen. Slowly add 1.3mol triethylenetetramine dropwise to the reactor, and the dropwise addition is completed within 1 hour, then react at a constant temperature of 150-160°C for 6h, cool to room temperature, and obtain an intermediate monoamide, and then add 1.1mol dehydroabietic acid, start stirring, heat up to 90°C under nitrogen protection, then react at a constant temperature of 150-160°C for 6h, cool to room temperature, use 150# solvent oil and butanone mixed solvent (volume ratio 1:1 ) recrystallized 3 times, removed by-products, and dried in a vacuum oven at 60°C to constant wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com