Hyphomicrobium sp. strain and preparation method for pyrroloquinoline quinone

A technology of pyrroloquinoline quinone and filamentous bacteria, which is applied in the field of microbial engineering, can solve the problems of low fermentation titer, cannot meet the needs of industrialized production, etc., and achieves the effects of stable genetic traits, excellent commercial application value, and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

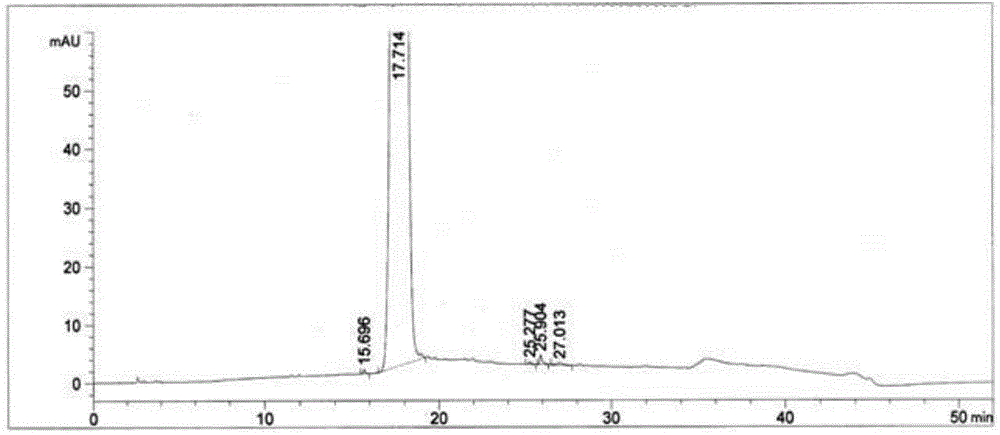

Image

Examples

Embodiment 1

[0044] Embodiment 1, the preparation of high-yield bacterial strain Hyphomicrobium CGMCC No.10709 (Hyphomicrobium sp.)

[0045] Get test bacterial classification 1112-NTG-1953, this bacterial classification obtains TK0415 from the soil sample of Holland (Netherlands) T (No. 1112-O-36) obtained through natural screening and UV mutagenesis screening. (Strain TK 0415 T See Teizi Urakami, Junko Sasaki, Ken-Ichiro Suzuki, etc., Characterization and Description of Hyphomicrobium denitrificans sp.nov., International Journal Of Systematic Bacteriology, Vol.45, No.3, p.528-532, July 1995)

[0046] Draw the suspension of glycerol tube bacteria and spread it on the slant of the test tube. The slant medium is (g / L): ammonium sulfate 1.00, magnesium sulfate heptahydrate 0.20, sodium dihydrogen phosphate 0.50, dipotassium hydrogen phosphate 1.55, methanol 1.20, agar 15.00 , pH7.2, cultured at 26-30°C for 4 days. Scrape the slanted bacteria to prepare the test strain suspension for mutage...

Embodiment 2

[0053] Embodiment 2: Fermentation small-scale test process research of hyphaemicrobial bacteria CGMCC No.10709 on 50L tank

[0054] Based on the process parameters obtained from the 250ml shake flask and referring to the characteristics of the mutant strain CGMCC No.10709, a 50L tank fermentation process was designed and optimized. The growth and metabolism of the mutant strains and the optimal production capacity of pyrroloquinoline quinone were investigated.

[0055] Seed medium (g / L), ammonium sulfate 2.0, potassium dihydrogen phosphate 1.6, disodium hydrogen phosphate 2.8, magnesium sulfate heptahydrate 0.3, methanol 1.2, pH 7.0.

[0056] Seed tank process control: seed medium loading volume is 10 / 15L, culture temperature is 26-30°C, stirring speed is 200-500rpm, dissolved oxygen is greater than 15%, air flow rate is 0.5-2.0, and the culture period is 3 days.

[0057] Fermentation medium (g / L), namely methanol 12.0, ammonium sulfate 5.0, yeast extract powder 5.0, potassiu...

Embodiment 3

[0061] Embodiment 3: Fermentation small-scale test process research of hyphaemicrobial bacteria CGMCC No.10709 on 50L tank

[0062] Based on the process parameters of Example 2, a 50L tank fermentation process was designed and optimized. The growth and metabolism of the mutant strains and the optimal production capacity of pyrroloquinoline quinone were investigated.

[0063] Seed medium (g / L), ammonium sulfate 2.0, potassium dihydrogen phosphate 1.6, disodium hydrogen phosphate 2.8, magnesium sulfate heptahydrate 0.3, methanol 1.2, pH 7.0.

[0064] Seed tank process control: seed medium loading volume is 10 / 15L, culture temperature is 26-30°C, stirring speed is 200-500rpm, dissolved oxygen is greater than 15%, air flow rate is 0.5-2.0, and the culture period is 3 days.

[0065] Fermentation medium (g / L), namely methanol 12.0, ammonium sulfate 5.0, yeast extract powder 5.0, potassium dihydrogen phosphate 2.0, disodium hydrogen phosphate 5.0, magnesium sulfate heptahydrate 0.6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com