Mould-proof edge sealing glue and preparation method, use method and application thereof

An edge-sealing adhesive and anti-mildew technology, which is applied in adhesives, household components, manufacturing tools, etc., can solve the problems that the edge-sealing adhesive does not have anti-mildew function, affects the appearance, pollutes articles, etc., and achieves good chemical stability and antibacterial Low concentration, good surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

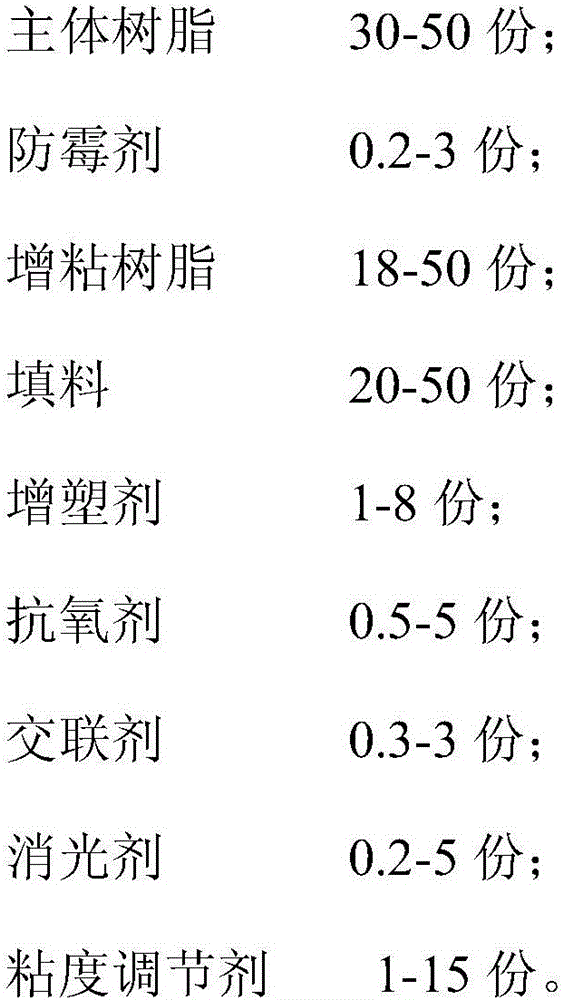

Method used

Image

Examples

preparation example Construction

[0044] A preparation method of mildew-proof edge banding glue, comprising the following steps:

[0045] 1) Put the main resin, tackifying resin and crosslinking agent of the formulated amount into the reaction kettle, and react at a temperature of 100-200°C for 2-3 hours to obtain the first mixture;

[0046] 2) Put the first mixture into a vacuum oven at a temperature of 120-150° C., and vacuum dehydrate for 1-2 hours to obtain the second mixture;

[0047] 3) After the temperature of the second mixture is lowered to 80-100°C, it is sent to the reactor again, and then fillers, plasticizers, and viscosity regulators are added in the prescribed amount, and the reactor is heated while stirring, until the temperature rises to After 100-120°C, keep for 0.8-1.5h to obtain the third mixture;

[0048] 4) When the temperature of the third mixture is lowered to 60-80°C, add the prescribed amount of anti-mold agent, antioxidant and matting agent, and stir for 0.5-1 hour to obtain the ant...

Embodiment 1

[0053] A kind of mildew-proof edge banding glue, prepared according to the following steps (see Table 1 for details of each component and dosage):

[0054] 1) Put the main resin, tackifying resin and crosslinking agent in the formula amount into the reaction kettle, and react at a temperature of 120°C for 2 hours to obtain the first mixture;

[0055] 2) Put the first mixture into a vacuum drying oven at a temperature of 120° C., and vacuum dehydrate for 2 hours to obtain the second mixture;

[0056] 3) After the second mixture is cooled to 90°C, it is sent to the reaction kettle again, and then the filler, plasticizer and viscosity regulator are added in the formula, the reaction kettle is heated and stirred at the same time, and the temperature rises to 100°C After, keep 0.8h, obtain the 3rd mixture;

[0057] 4) When the temperature of the third mixture is lowered to 60° C., add the prescribed amount of anti-mold agent, antioxidant and matting agent, and stir for 0.5 h to ob...

Embodiment 2

[0059] A kind of mildew-proof edge banding glue, prepared according to the following steps (see Table 1 for details of each component and dosage):

[0060] 1) Put the main resin, tackifying resin and crosslinking agent of the formulated amount into the reaction kettle, and react at a temperature of 150°C for 2.6 hours to obtain the first mixture;

[0061] 2) Put the first mixture into a vacuum drying oven at a temperature of 140° C., and vacuum dehydrate for 1.5 hours to obtain the second mixture;

[0062] 3) After the second mixture is cooled to 85°C, it is sent to the reaction kettle again, and then the filler, plasticizer, and viscosity modifier are added in the formula, and the reaction kettle is heated while stirring, until the temperature rises to 110°C After that, keep 1h to obtain the third mixture;

[0063] 4) When the temperature of the third mixture is lowered to 75° C., add the prescribed amount of anti-mold agent, antioxidant and matting agent, and stir for 0.9 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com