Glass ceramics, process for preparing same and remote warm white-light LED device

A technology of glass-ceramics and LED chips, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of lack of red components, restricted material application, low color rendering index, etc., achieve good thermal and chemical stability, and low cost , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0030] A preparation method of glass-ceramic, characterized in that, making the above-mentioned double-layer remote fluorescent body comprises the following steps:

[0031] Step 1, the 21SiO 2 -18Sb 2 o 3 -9BaO-25Y 2 o 3 -24Al 2 o 3 -1CeO 2 (mol%) and powder rare earth oxide 0.5Pr 6 o 11 -0.2Sm 2 o 3 -0.8La 2 o 3 -0.5Tb 4 o 7 The powder raw materials are accurately weighed according to the proportion and put into the ball mill tank, then add agate balls of the same quality and different size as the mixture, and mill on the ball mill for 2 hours;

[0032]Step 2, move the uniformly mixed glass powder into a corundum crucible and heat it in a resistance furnace, and keep it at 1300°C for 3 hours to fully melt it;

[0033] Step 3, quickly pour the glass melt into a mold to form it, and put it into a resistance furnace for annealing at 650°C for 2 hours to eliminate internal stress, so as to obtain a bulk precursor glass;

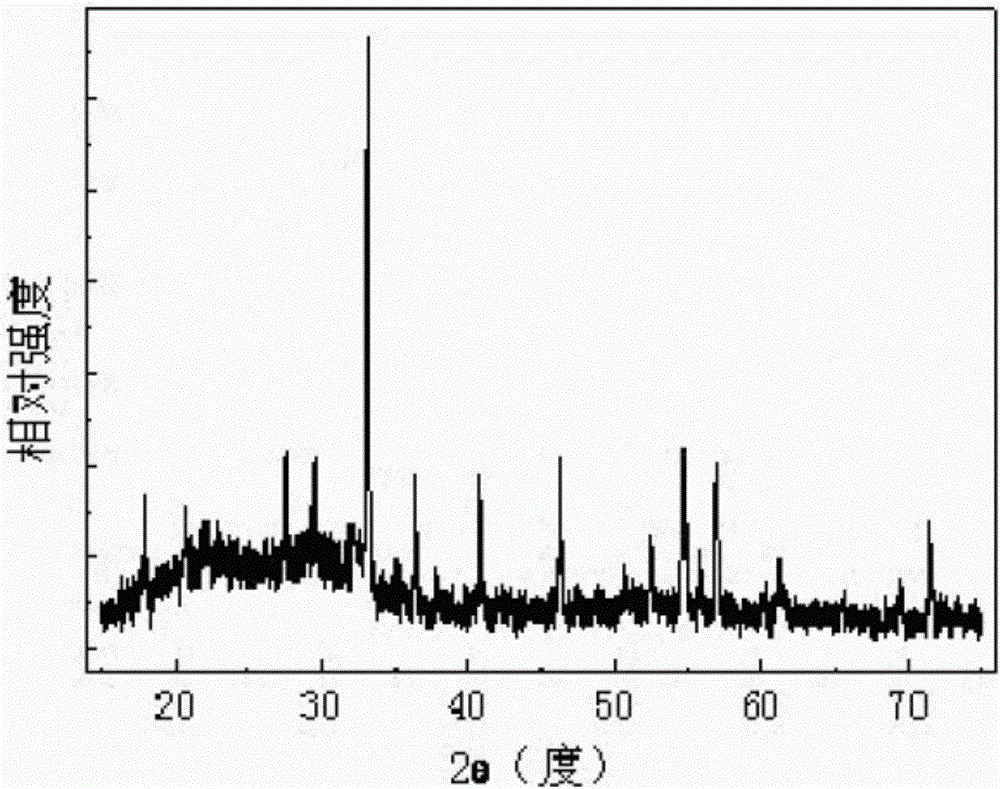

[0034] Step 4: put the obtained precursor ...

specific Embodiment 2-4

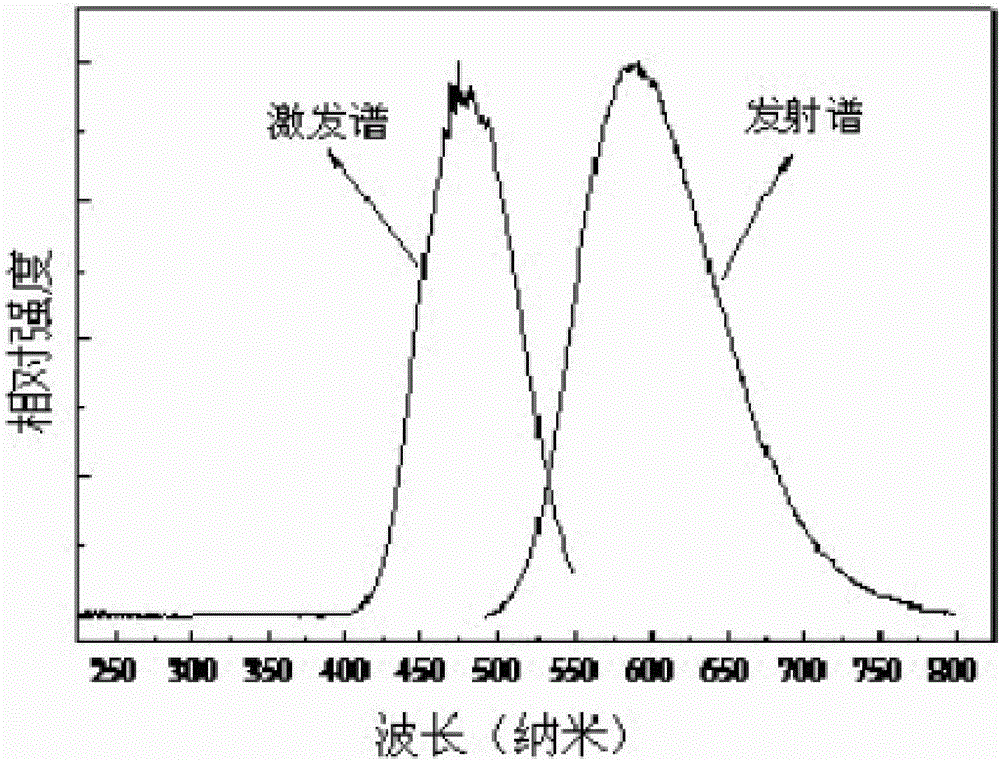

[0040] The ratio of raw materials in Example 1 was changed (see Table 1, Table 2), and the process conditions were kept constant to obtain corresponding glass-ceramics respectively. The remote packaging technology is used to package the blue light chip with a rated power of 3W and an emission wavelength of 475nm and glass-ceramic glass into an LED device, and conduct a performance test on it. All remote glass-ceramic glass sheets emit orange light after being excited by the blue light chip, and the combination of the orange light and the blue light passing through the glass-ceramic produces bright warm white light.

[0041] Glass raw material proportioning in the present embodiment 2-4 of table 1

[0042]

[0043] Re raw material proportioning in the present embodiment 2-4 of table 2

[0044]

[0045]

[0046] refer to Figure 5 as shown,

[0047] A remote warm white LED device, comprising a lamp body 1, a blue light chip 2, a reflector 3, a light mixing cavity 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com