Rare earth heavy metal waste liquid treatment method

A waste liquid treatment and heavy metal technology, applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as environmental pollution, resource loss, and loss of precious rare earth resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

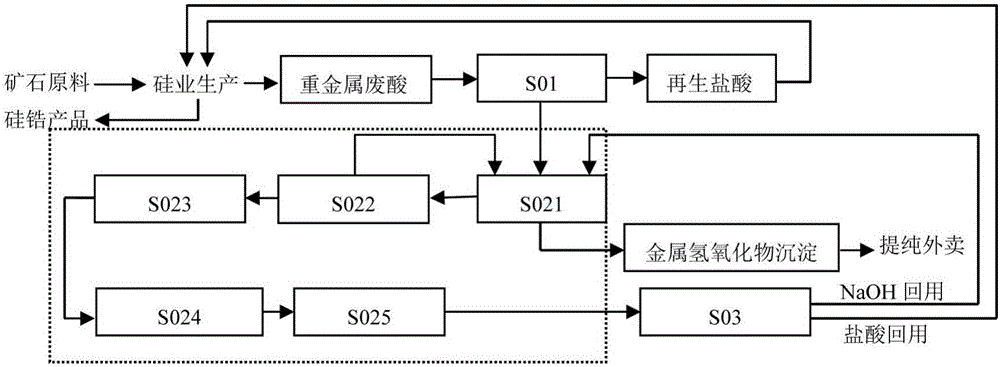

[0024] like figure 1 Shown, a kind of rare earth heavy metal waste liquid processing method of the present invention comprises the steps:

[0025] S01: Diffusion dialysis; pass the waste liquid into the diffusion dialysis unit to separate hydrochloric acid from the waste liquid, and the hydrochloric acid obtained by dialysis can be returned to figure 1 In the production of the silicon industry shown; the composition of the waste liquid after acid removal by diffusion dialysis is: H 2 O 95.84%, HCl 1.59%, ScCl 0.39%, others 2.18%;

[0026] S02: preprocessing, including the following steps:

[0027] S021: Alkali neutralization; pass the waste liquid into the alkali neutralization unit for 10 minutes of treatment, so that the rare earth heavy metal ions in the waste liquid and OH - Combine to form Sc(OH) 3 Precipitation, so that the rare earth heavy metal element Sc is extracted from the waste liquid;

[0028] S022: nanofiltration separation; pass the waste liquid into the n...

Embodiment 2

[0034] like figure 1 Shown, a kind of rare earth heavy metal waste liquid processing method of the present invention comprises the steps:

[0035] S01: Diffusion dialysis; pass the waste liquid into the diffusion dialysis unit to separate hydrochloric acid from the waste liquid, and the hydrochloric acid obtained by dialysis can be returned to figure 1 In the production of the silicon industry shown; the composition of the waste liquid after acid removal by diffusion dialysis is: H 2 O 96.26%, HCl 1.47%, ScCl 0.46%, others 1.81%;

[0036] S02: preprocessing, including the following steps:

[0037] S021: Alkali neutralization; pass the waste liquid into the alkali neutralization unit for continuous 90min treatment, so that the rare earth heavy metal ions in the waste liquid and OH - Combine to form Sc(OH) 3 Precipitation, so that the rare earth heavy metal element Sc is extracted from the waste liquid;

[0038] S022: Nanofiltration separation; pass the waste liquid into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com