Lampblack depuration machine

A technology of oil fume purifier and oil fume hood, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, and the use of liquid separation agents, etc. It can solve the problems of difficult cleaning, not smooth, and low oil smoke exhaust rate, so as to protect the environment and control the epidemic , the effect of pollution control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

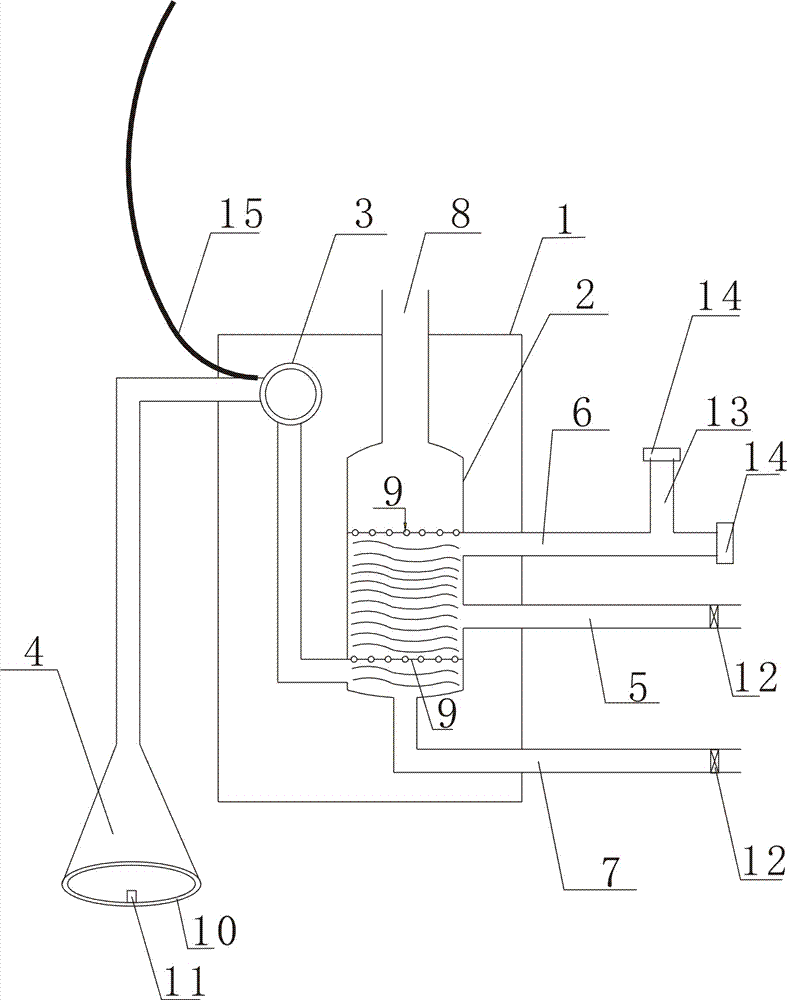

[0015] Such as figure 1 As shown, the oil fume purifier includes a casing 1. A water container 2 is arranged inside the casing 1. The water container 2 is connected to a fan 3 through a pipeline, and the fan 3 is connected to a fume hood 4 through a pipeline. The water container 2 is connected to a Water inlet pipe 5, overflow pipe 6, overflow pipe 6 is positioned at the top of water inlet pipe 5, is provided with blowdown pipe 7 at the bottom of water container 2, and is provided with air outlet 8 at the top of water container 2.

[0016] The water container 2 is provided with two interlayers 9, wherein one interlayer 9 is located above the liquid level of the water, and the other interlayer 9 is located at the bottom of the water container 2 and connected to the pipeline.

[0017] The blower fan 3 is installed on the air exhaust port 8 .

[0018] The fume hood 4 is conical, and the fume hood 4 is provided with an oil guide groove 10 and an oil cup 11 .

[0019] The oil fum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com