Fe-MCM-41/CA blend film and preparing method and application thereof

A blended membrane, fe-mcm-41 technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of difficult recycling and reuse, easy loss, etc., and achieve stable physical and chemical properties, not easy to lose , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of Fe-MCM-41 / CA blended film includes the following steps:

[0028] 1) Dissolve sodium silicate, ferric nitrate and template in water to obtain corresponding solutions;

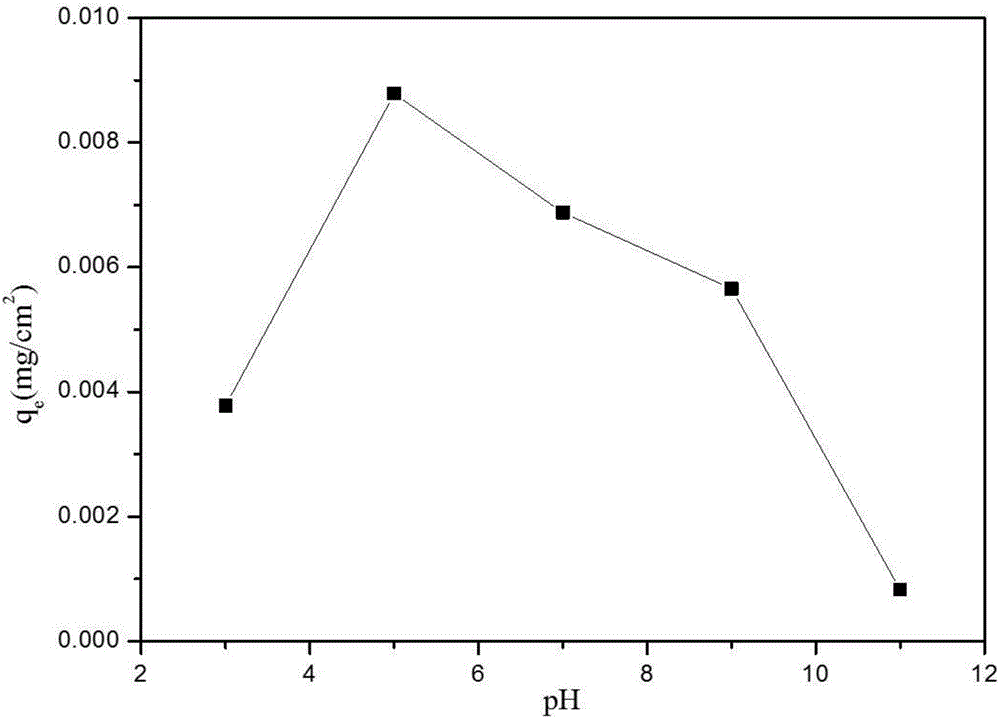

[0029] 2) Mix the ferric nitrate solution and the sodium silicate solution evenly, add the acid until the sol appears in the solution, stir well, then add the template agent solution, stir evenly to obtain the mixture, adjust the pH value to 9-11, hydrothermally crystallize, The crystalline product is separated, washed, dried, calcined and ground to obtain Fe-MCM-41 molecular sieve;

[0030] 3) Mix the porogen and the solvent evenly, add Fe-MCM-41 molecular sieve, stir evenly, then add cellulose acetate, stir evenly, and defoam to obtain a casting liquid;

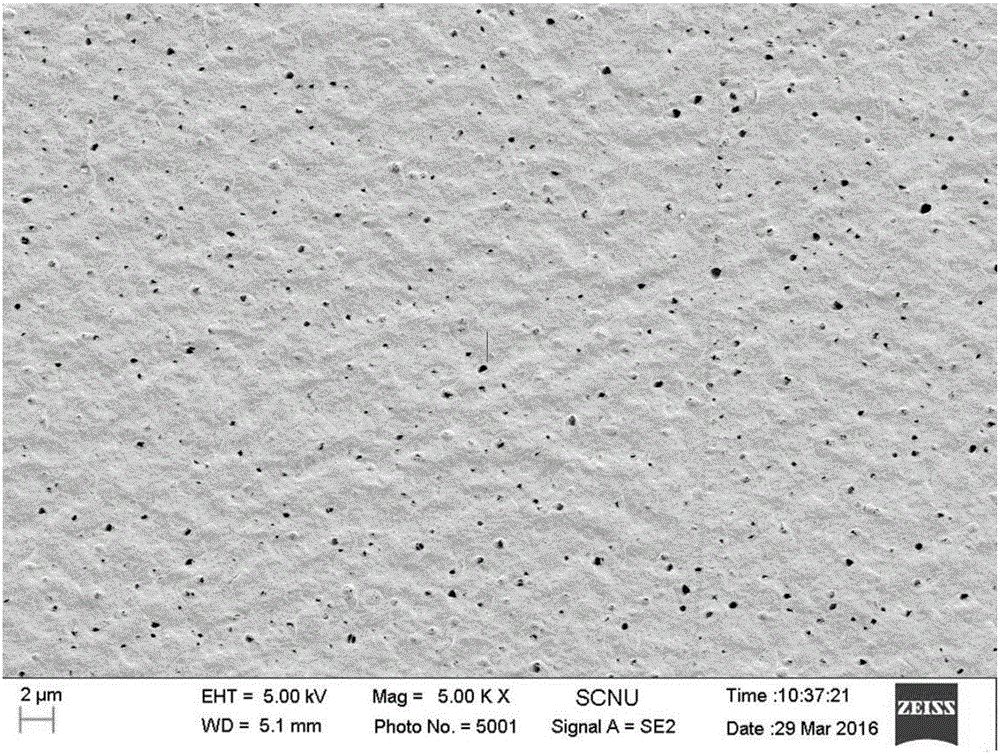

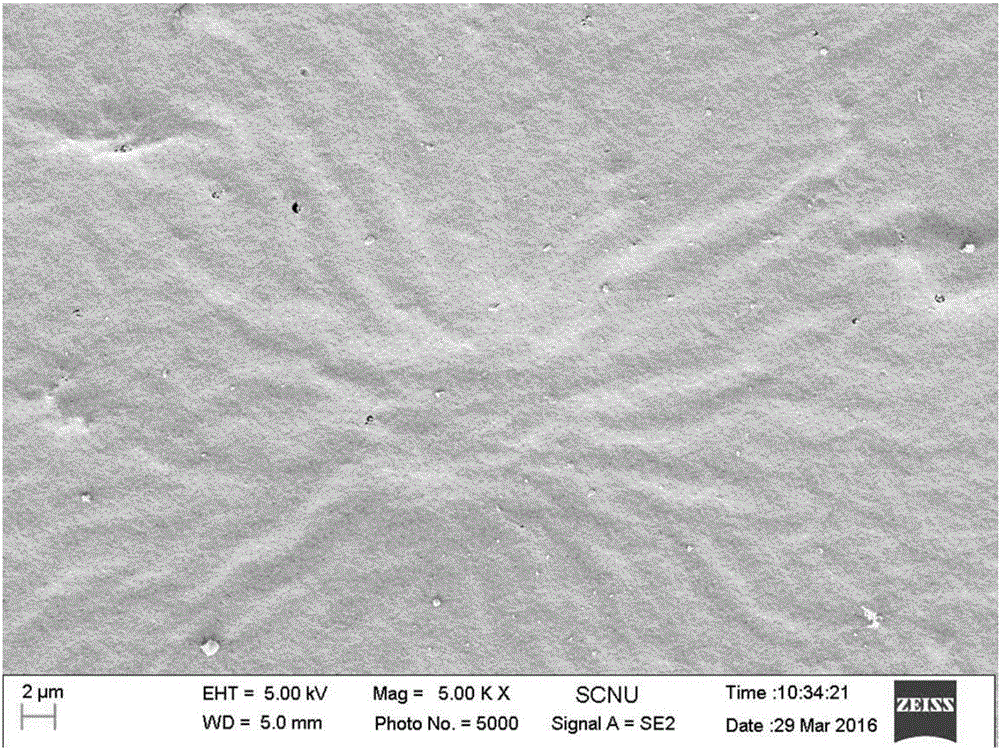

[0031] 4) Pour the casting liquid on the glass plate, scrape it with a spatula to form a thin liquid layer of uniform thickness, and then immerse the glass plate in deionized water in the coagulation bath to gel into a film to obtain Fe...

Embodiment 1

[0043] Preparation of Fe-MCM-41 molecular sieve:

[0044] 1) Prepare Na separately 2 SiO 3 Solution (28.7g Na 2 SiO 3 ·9H 2 O+65mL deionized water), Fe(NO 3 ) 3 Solution (0.202g Fe(NO 3 ) 3 ·9H 2 O+10mL deionized water) and CTAB solution (7.28g CTAB+25mL deionized water);

[0045] 2) Add Fe(NO 3 ) 3 Solution add Na 2 SiO 3 In the solution, stir for 15min, then add 2mol·L dropwise -1 Sulfuric acid solution until sol appears, continue to stir for 30 minutes;

[0046] 3) Add CTAB solution, stir for 30min, adjust pH=10.5~11 to obtain a mixed solution, crystallize at 145℃ for 48h, cool to room temperature, filter and wash, and dry the washed crystalline product under vacuum at 80℃ and flatten , Calcined in a muffle furnace at 550°C for 5 hours and ground to obtain Fe-MCM-41 molecular sieve.

[0047] Preparation of Fe-MCM-41 / CA blend film:

[0048] 1) Dissolve 0.6g polyvinylpyrrolidone in 51.6g N,N-dimethylacetamide to obtain a N,N-dimethylacetamide solution of polyvinylpyrrolidone;

[0049] ...

Embodiment 2

[0057] Preparation of Fe-MCM-41 molecular sieve:

[0058] The same as in Example 1.

[0059] Preparation of Fe-MCM-41 / CA blend film:

[0060] 1) Dissolve 0.6g of polyvinylpyrrolidone in 54.0g of N,N-dimethylacetamide to obtain an N,N-dimethylacetamide solution of polyvinylpyrrolidone;

[0061] 2) Add 0.48g Fe-MCM-41 and ultrasonic for 30min;

[0062] 3) Add 7.2g of cellulose acetate (CA), stir at 60°C for 6 hours, and then degas at 60°C for 12 hours to obtain a casting solution;

[0063] 4) Pour the casting liquid on the smooth glass, scrape it with a doctor blade, and then form a film in a coagulation bath of deionized water to obtain a Fe-MCM-41 / CA blend film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com