Aluminum oxide film layer license plate frame

A technology of aluminum oxide film and license plate frame, which is applied in vehicle parts, transportation and packaging, etc., can solve the problems of high price, corrosion resistance, and unsatisfactory wear resistance, and achieve superior high temperature performance, wear resistance and decoration Improvement of performance and improvement of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

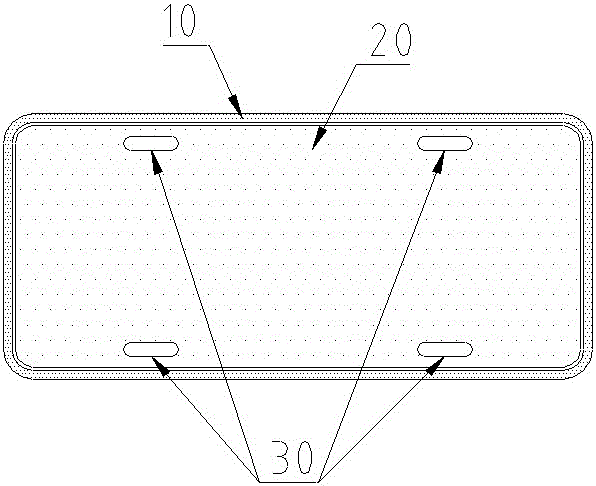

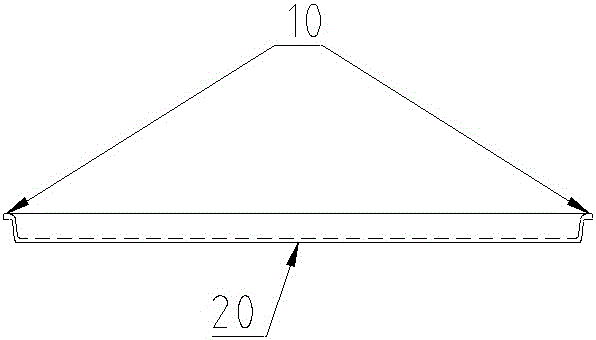

[0016] Such as figure 1 , figure 2 As shown, an aluminum oxide film license plate frame includes a license plate frame body, the license plate frame body includes a raised edge and a groove integrally formed with it, and the bottom of the groove is provided with 4 mounting holes that meet relevant national standards , the surface of the license plate frame body has an aluminum oxide film layer; the inside of the license plate frame body is a special aluminum strip for motor vehicle license plates; the thickness of the aluminum oxide film layer is 3-5um; the thickness of the license plate frame body is 0.6-1mm .

[0017] During the implementation of the present invention, through the anodic oxidation production process, after forming a layer of aluminum oxide film layer with a thickness of 3um on the surface of the special aluminum strip with a thickness of 0.6mm, the material with a suitable size is cut out and punched to obtain the actual need. After the edge 10 and the gr...

Embodiment 2

[0019] Such as figure 1 , figure 2 As shown, an aluminum oxide film license plate frame includes a license plate frame body, the license plate frame body includes a raised edge and a groove integrally formed with it, and the bottom of the groove is provided with 4 mounting holes that meet relevant national standards , the surface of the license plate frame body has an aluminum oxide film layer; the inside of the license plate frame body is a special aluminum strip for motor vehicle license plates; the thickness of the aluminum oxide film layer is 3-5um; the thickness of the license plate frame body is 0.6-1mm .

[0020] During the implementation of the present invention, through the anodic oxidation production process, after forming an aluminum oxide film layer with a thickness of 5um on the surface of the special aluminum strip with a thickness of 1mm, the material with a suitable size is cut out and punched to obtain the actually required bump. After the edge 10 and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com