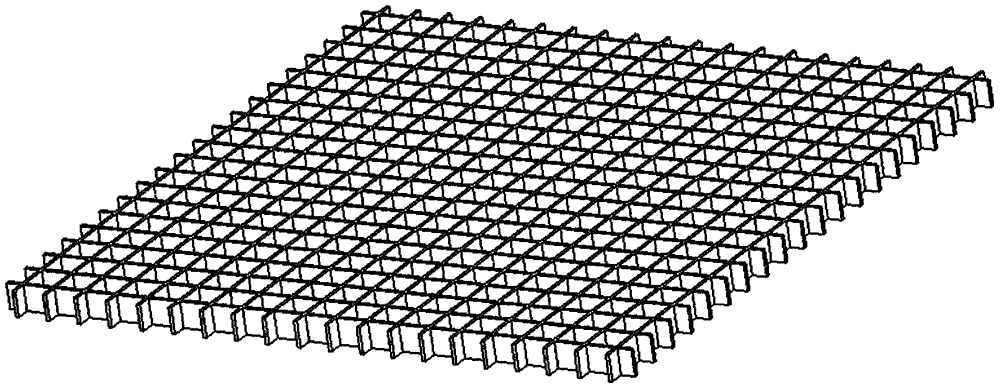

Orthogonal card core metal honeycomb plate

A metal honeycomb and card core technology is applied in the field of honeycomb sandwich structure sheet and metal honeycomb panel to achieve the effect of improving rigidity and strength, ensuring the quality of finished products, and reducing the cost of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 25mm×600mm×2000mm Orthogonal Card Core Magnesium Alloy Honeycomb Panel

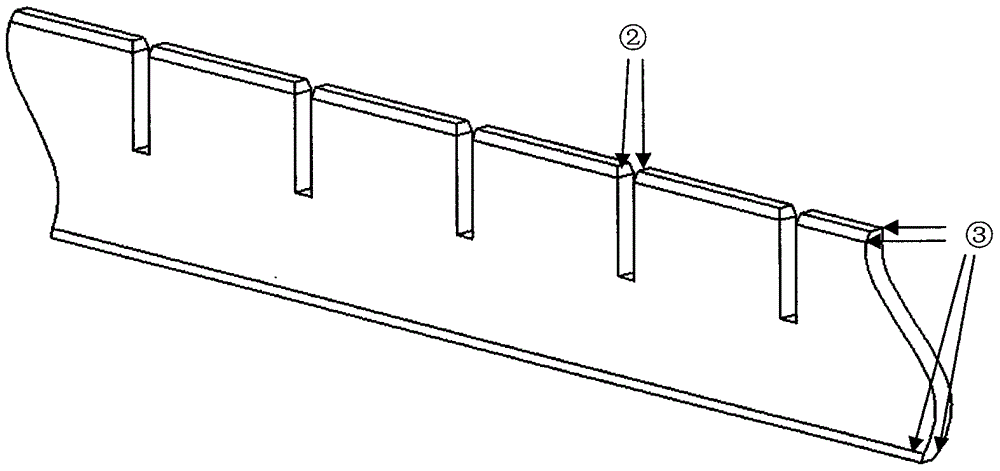

[0042] Panel: AZ91D precision-rolled magnesium alloy plate, 1.5mm thick, with V-shaped grooves on the inner surface, center distance between row / column of groove matrix 5.0mm, V-shaped groove depth 0.2mm, groove edge chamfer 15°, countersunk head rivet holes The center coincides with the center of a certain square of the V-groove matrix, the hole spacing is 50mm, the diameter of the outer circle of the hole is 5.0mm, the diameter of the inner circle is 3.0mm, and the chamfer is 45°;

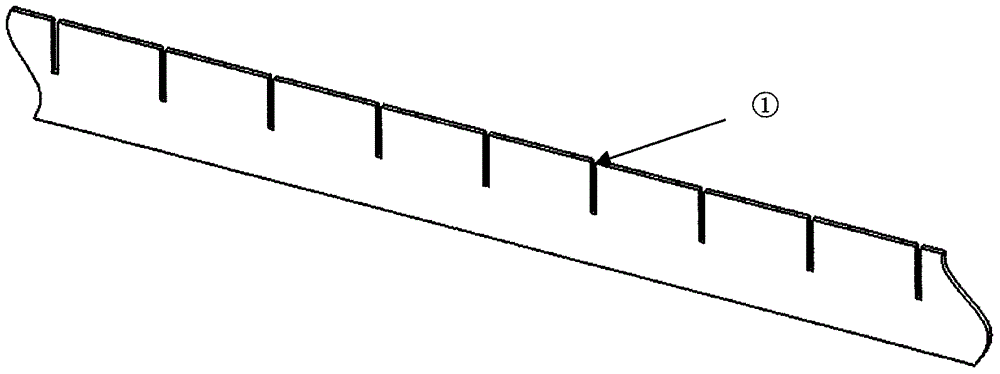

[0043] Plug-in honeycomb core slats: using magnesium alloy AZ91D finish-rolled plate, 0.4mm thick, 22.4mm wide, grooved at 5.0mm interval on one side, groove width 0.4+0-0.02mm, groove depth 11.2mm, the top of the groove is inverted The angle is 0.2mm / 15°, and the chamfer on both sides of the slat is 0.2mm / 15°;

[0044] Pairs of countersunk rivets: M3 specification, cap diameter 5mm: vertical and horizontal...

Embodiment 2

[0049] Example 2 35mm x 1200mm x 3000mm wide orthogonal core magnesium alloy honeycomb panel

[0050] Panel: AZ91D precision-rolled magnesium alloy sheet, 2.0mm thick, with V-shaped grooves on the inner surface, center distance between row / column of groove matrix 5.0mm, V-shaped groove depth 0.2mm, groove edge chamfer 15°, countersunk rivet holes The center coincides with the center of a certain square of the V-groove matrix, the hole spacing is 50mm, the diameter of the outer circle of the hole is 5.0mm, the diameter of the inner circle is 3.0mm, and the chamfer is 45°;

[0051] Plug-in honeycomb slats: using magnesium alloy AZ91D finish-rolled plate, 0.4mm thick, 31.4mm wide, grooved at 5.0mm interval on one side, groove width 0.4+0-0.02mm, groove depth 15.7mm, the top of the groove is inverted The angle is 0.2mm / 15°, and the chamfer on both sides of the slat is 0.2mm / 15°;

[0052] Pairs of countersunk rivets: M3 specification, cap diameter 5mm: vertical and horizontal spac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com