Archaistic wood floor surface treatment method

A surface treatment, wood floor technology, applied in manual woodworking tools, wood processing appliances, manufacturing tools, etc., can solve the problems of inferior production effect, dull product performance, lack of aura, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the drawings.

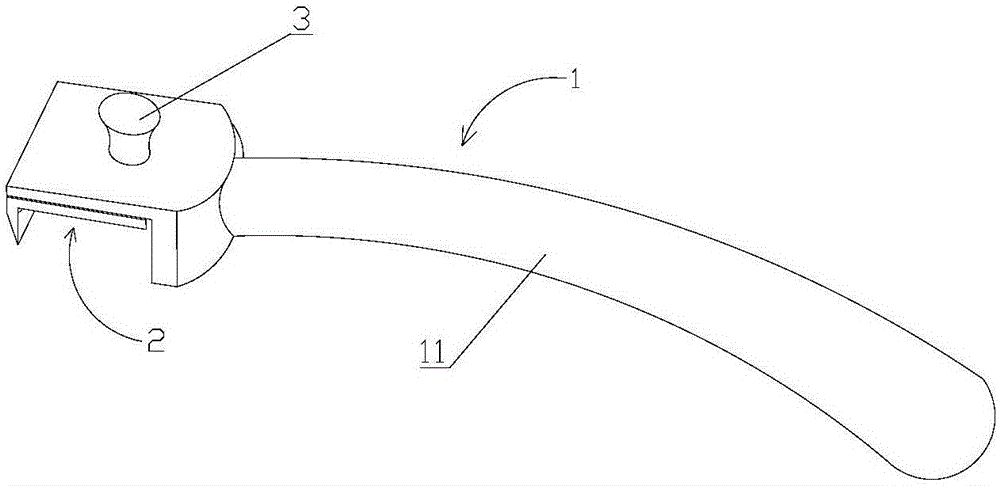

[0021] figure 1 The hand scraper used in the antique wooden floor surface treatment method according to an embodiment of the present invention is schematically shown. As shown in the figure, the device includes a handle 1 and a blade 2 fixed below the front of the handle 1. The blade 2 is detachably connected to the handle 1 by a bolt 3.

[0022] Among them, the handle 1 is a wear-resistant rubber handle, and the blade 2 is a spring steel blade.

[0023] The handle 1 has a curved handle 11.

[0024] The front end of the blade 2 has a cutting edge bent downward. The angle a between the cutting edge and the blade 2 is 80-95 degrees.

[0025] The cross section of the blade is a right triangle, and the slope of the blade is located on the outside. As a result, the blade is sharper and it is easier to sharpen the knife. The opening angle of the blade is 10 degrees.

[0026] The bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com