Wood processing production line with waste recycling function

A waste recycling and production line technology, applied to wood processing equipment, manufacturing tools, bark areas/debris/dust/waste removal, etc., can solve problems such as increasing mechanical loss, affecting the service life of machinery, and affecting the health of workers , to prolong the service life of the machine and ensure the health of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

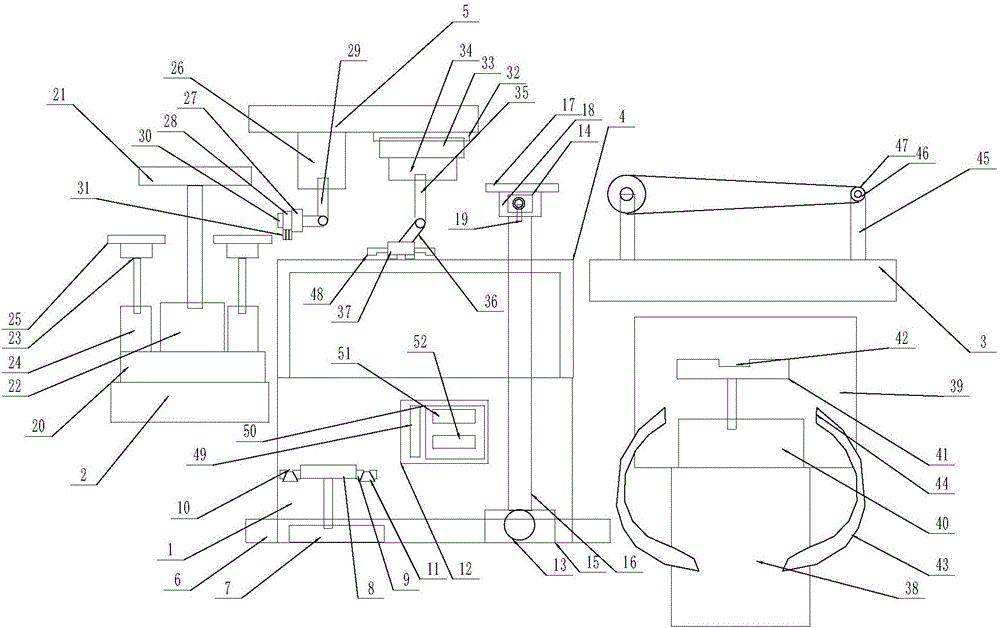

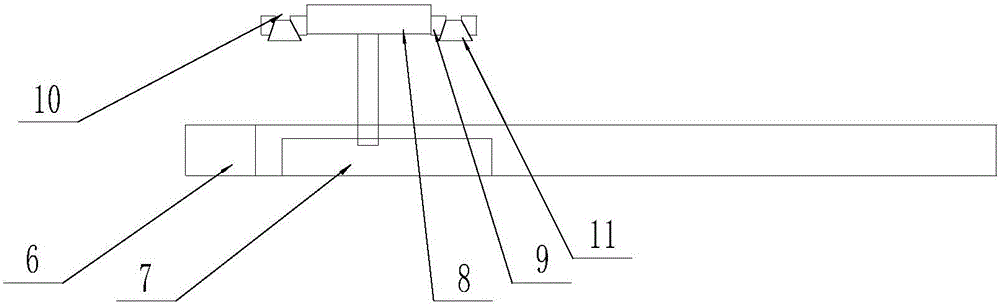

[0018] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a wood processing production line with waste recycling function includes a workbench (1) and auxiliary conveyor belts (2) and conveyor racks (3) respectively arranged on the left and right sides of the workbench (1). 2) A grinding unit is provided on the top, a laser engraving unit is provided on the rear side of the workbench (1), a beam (4) is provided on the upper surface of the workbench (1), and a bearing plate is provided on the beam (4) (5), the carrying plate (5) is provided with a cutting unit and a clamping unit, the transfer frame (3) is provided with a transfer unit, and the front side of the workbench (1) is provided with a waste transfer unit, The waste parts transfer unit is composed of a base (6) arranged on the front side of the workbench (1), a No. 1 rotating motor (7) which is arranged in the base (6), and the rotating end extends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com