A motion planning method for additional axes in the work cell of a gantry-type hoisting robot

A technology of work unit and motion planning, which is applied to manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of large range of robot joint changes, and achieve the effect of improving work adaptability, reducing joint changes, and continuous and stable motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, take Fanuc's 1-M-20iA model robot as an example, and describe the embodiment of the present invention in detail in conjunction with the accompanying drawings.

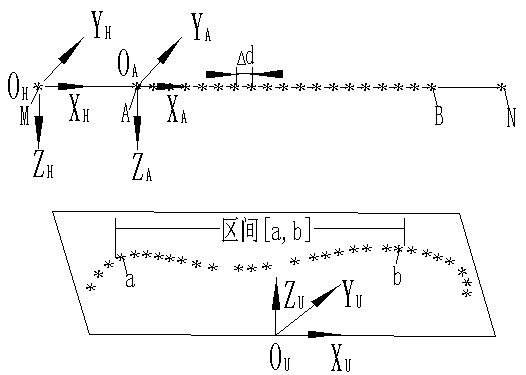

[0032] Such as figure 1 As shown, the working unit of the gantry-type hoisting robot consists of a linear guide rail 1, a slide table 2, an industrial robot 3, a workbench 4, and a processing track point 5.

[0033] Such as figure 2 As shown, a motion planning method for an additional axis in a gantry-type hoisting robot work cell, the additional axis includes a linear guide rail and a slide table, including the following steps:

[0034] The first step: if image 3 As shown, establish the user coordinate system on the workbench {O U x U Y U Z U}; Establish the zero point coordinate system of the guide rail at the zero point M of the linear guide rail {O H x H Y H Z H}, the direction of the OX axis is the movement direction of the sliding table (ie, the axis direction of the guide rail); t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com