A method for controlling the stop angle of the roll head of a hot rolling roll grinder

A technology of stopping angle and control method, which is applied in the direction of grinding automatic control device, grinding machine parts, manufacturing tools, etc. Avoid incorrect roll head angle and smooth grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

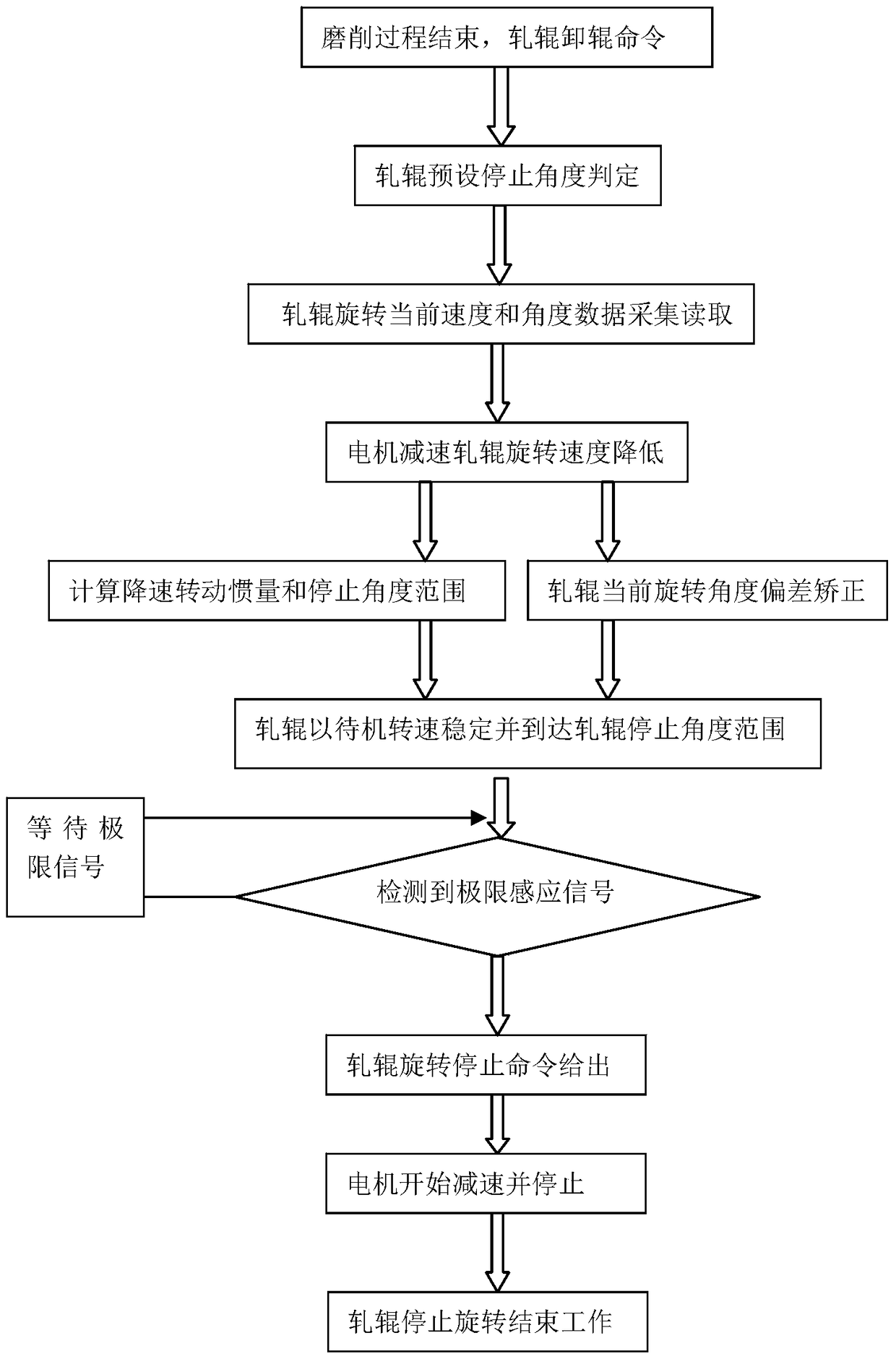

[0023] Such as figure 1 As shown, a method for controlling the stop angle of the roll head of a hot rolling roll grinder uses the bedside motor encoder to collect the current rotation angle and speed of the roll, and the signal of the positioning limit is switched on and off to correct the current roll rotation angle, and the roll stop command is executed when the angle is matched. The specific control method is as follows:

[0024] 1) When the roll grinding is qualified and meets the roll unloading conditions, the automatic control system gives the roll unloading command, and the grinding machine automatically returns to the initial grinding position;

[0025] 2) The automatic control system judges the preset data of the stop angle of the roll, and the preset value of the stop angle of the roll is set to 90°;

[0026] 3) The encoder KTY84ENCODER_D01_2048_SR installed on the bedside motor collects the angle and speed of the roll rotation. The numerical control system reads th...

Embodiment 2

[0032] Such as figure 1 As shown, a method for controlling the stop angle of the roll head of a hot rolling roll grinder uses the bedside motor encoder to collect the current rotation angle and speed of the roll, and the signal of the positioning limit is switched on and off to correct the current roll rotation angle, and the roll stop command is executed when the angle is matched. The specific control method is as follows:

[0033] 1) When the roll grinding is qualified and meets the roll unloading conditions, the automatic control system gives the roll unloading command, and the grinding machine automatically returns to the initial grinding position;

[0034] 2) The automatic control system judges the preset data of the stop angle of the roll, and the preset value of the stop angle of the roll is set to 0°;

[0035] 3) The encoder KTY84ENCODER_D01_2048_SR installed on the bedside motor collects the rotation angle and speed of the roll. The numerical control system reads the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com