A method for processing joint parts

A technology for parts processing and parts, applied in the field of joint parts processing, can solve problems such as errors, and achieve the effects of high processing accuracy, improved bearing capacity, and shortened waiting period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

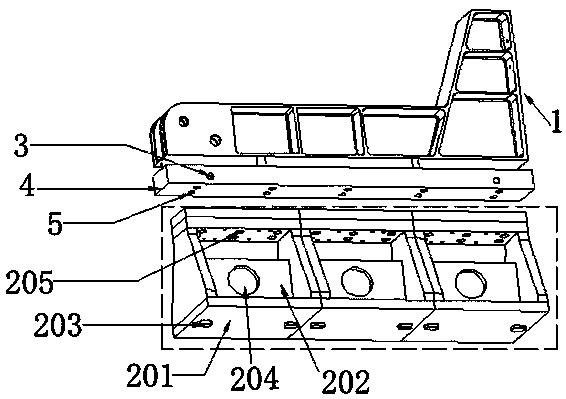

[0037] Such as image 3 Shown: The structure of the upper and lower parts of the joint part 1 is asymmetric; it includes a large number of rib structures and side grooves; the part has a thin-walled structure, and the thickness of the smallest part is only 1.5mm. The part has high machining accuracy and is easy to deform.

[0038] For this joint part 1, the analysis found that the difficulty in processing lies in effectively controlling the deformation generated during the processing of the part, maintaining the stable processing state of the part, reducing the turning and clamping work of the part, reducing the labor intensity of the operator, and improving the processing efficiency. efficiency.

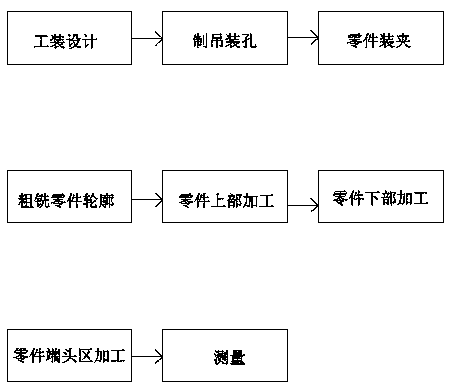

[0039] Concrete processing flowchart of the present invention is as figure 1 shown.

[0040] A. Tooling design: In view of the structural characteristics and machine tool characteristics of the joint parts 1, in order to ensure the processing quality, design special tooling such a...

Embodiment 2

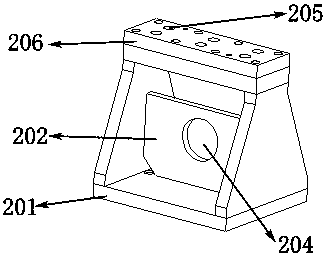

[0050] On the basis of Embodiment 1, preferably, the tooling of the present invention includes an upper surface 206, a base 201 and a reinforcing rib 202; the base 201 includes a bottom surface and two sides perpendicular to the bottom surface; the upper surface 206 and the base 201 is connected in a ring shape; the reinforcing rib 202 is connected between the vertical two sides of the base 201; the reinforcing rib 202 is perpendicular to the vertical two sides; the reinforcing rib 202 is perpendicular to the bottom surface; the bottom surface of the base 201 is provided with The positioning key 203; the reinforcing rib 202 is provided with a lightening hole 204.

Embodiment 3

[0052] On the basis of Embodiment 1, preferably: in step D, in the rough milling part contour step, a three-coordinate general-purpose machine tool is used to ensure that the margin on one side is not less than 10mm, and the contour is cut off. In this way, the weight of the blank can be appropriately reduced, and it is convenient for the workers to clamp; a suitable machining allowance can ensure that the blank itself has good rigidity when the finishing is stripped from the top to the bottom layer, and the blank will not vibrate during the processing, thus ensuring Processing quality of parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com