A method to ensure that the deformed steel plate smoothly passes through the swinging roller table of the cutting head shear

A technology of cutting head shears and swinging rollers, which is applied to the attachments of shearing machines, shearing devices, metal processing equipment, etc., which can solve the problems of easily damaged attachments, lack of guard plate protection, and steel plates drilling into the roller table. , to reduce accident time and spare parts costs, improve product competitiveness, and save maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

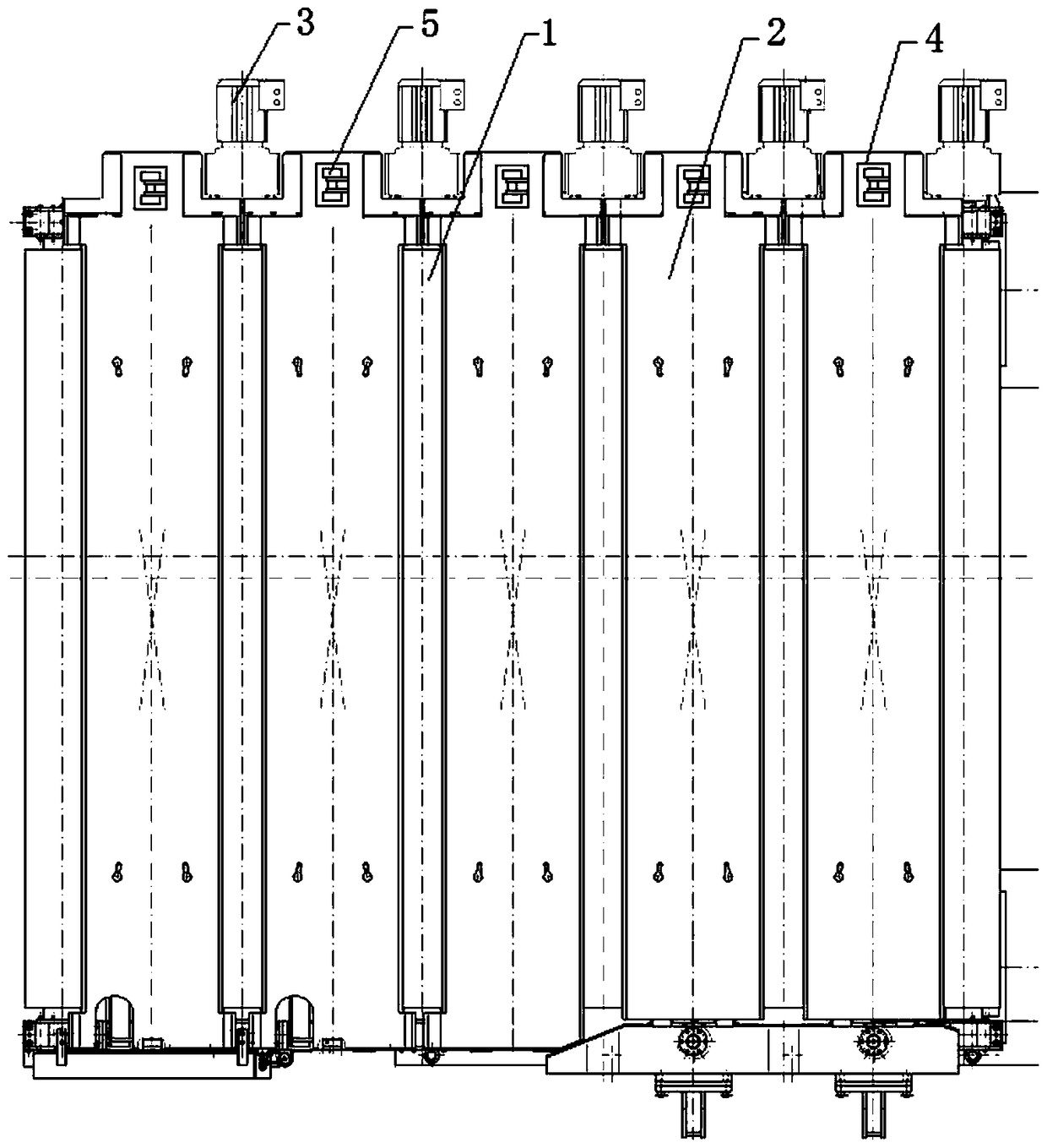

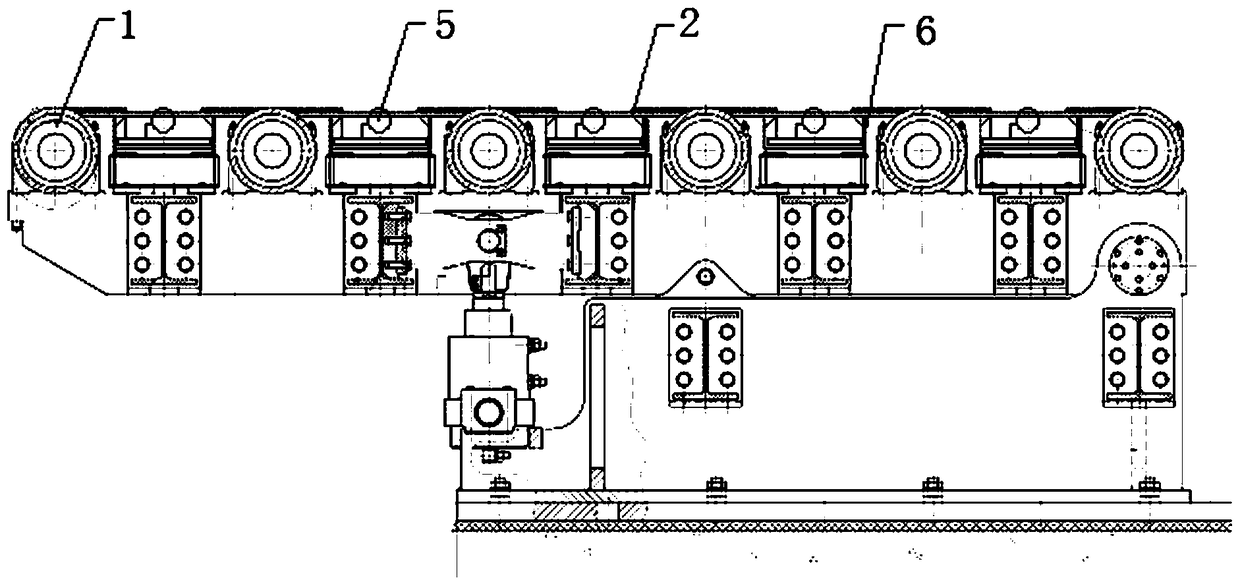

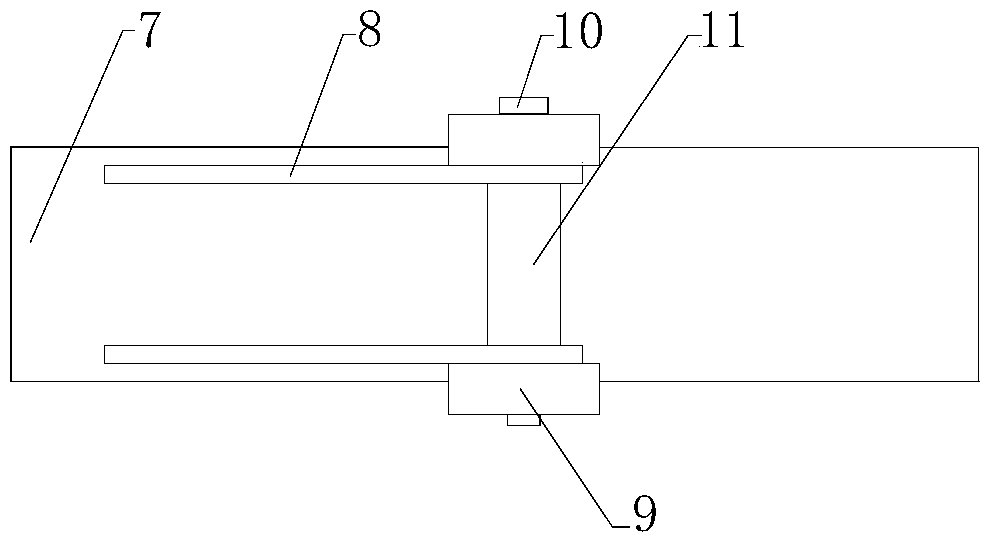

[0020] Such as Figure 1-Figure 2 As shown in the figure, a guide device is installed under the roller guard plate of the swing roller table of the crop shear. The guide device is installed under the adjacent roller guard plate on the side of the geared motor. The rollers in the guide device are at the same height as the swing roller table, and the deformed steel plate It is jointly supported and guided by the swinging roller table and the guide device, so that the roller table guard plate does not contact the deformed steel plate.

[0021] A oscillating roller table for crop shears to ensure the smooth passage of deformed steel plates, including a oscillating roller table 1 and a roller table guard 2, the roller table 1 is driven to rotate by a reduction motor 3, and the roller table between the adjacent roller table 1 on the side of the reduction mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com