A new-type automobile rear axle hub end face milling device and an operation method thereof

A face milling and automobile technology, applied in the field of auto parts processing, can solve the problems of difficult control of hydraulic oil feed, unqualified workpieces, unfavorable 5S site management, etc., to avoid unqualified workpieces, high production efficiency, and reduce labor effect of complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

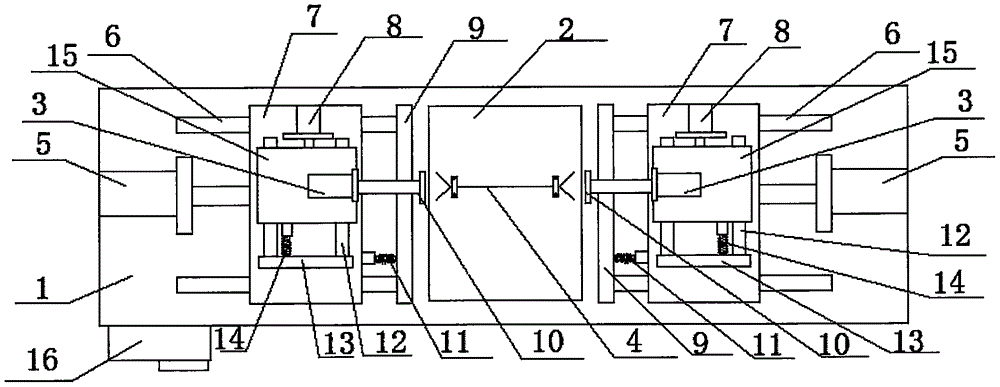

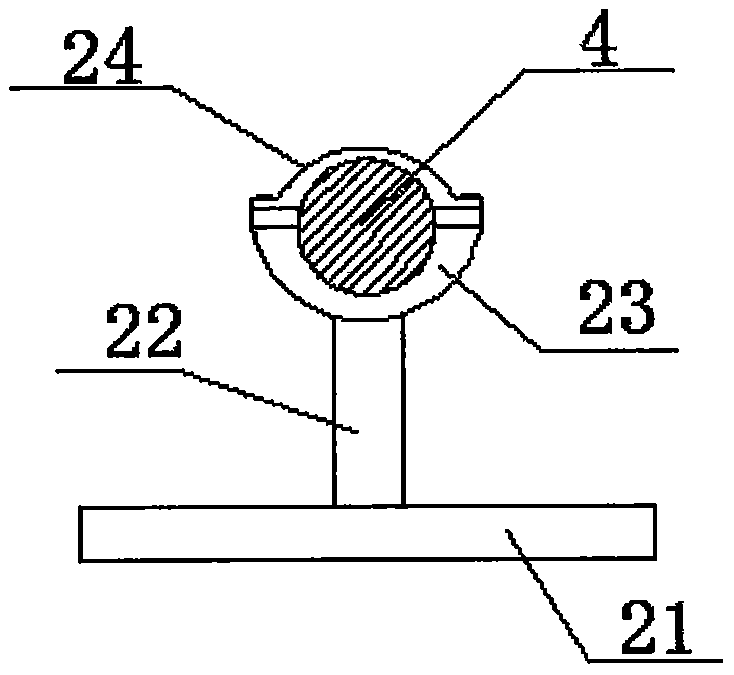

[0023] figure 1 with figure 2 A specific embodiment of the present invention is shown: a novel automobile rear axle wheel hub end face milling device, comprising a workbench 1 and a PLC control device 16 arranged on the workbench 1, the workbench 1 is provided with a positioning tool 2, and the automobile rear axle The shaft hub 4 is arranged on the positioning tool 2 , and the symmetrical sides of the positioning tool 2 are respectively provided with servo system actuators, and the servo system actuators are respectively electrically connected to the PLC control device 16 .

[0024] In this embodiment, the actuator of the servo system includes a first push rod motor 5, a second push rod motor 8 and a rotary motor 3. The workbench 1 is provided with a first slide rail 6 arranged in parallel, and the first slide rail 6 is provided with There is a mounting plate 7, the mounting plate 7 is slidingly connected with the first slide rail 6, the first push rod motor 5 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com