Device and method for automatic glue removal and filling of filter elements

A filter and glue pouring technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of motor overheating and burning, large glue delivery resistance, and easy pollution of gears, so as to reduce the glue suction resistance and prolong the life of the machine. The effect of service life and stable glue suction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

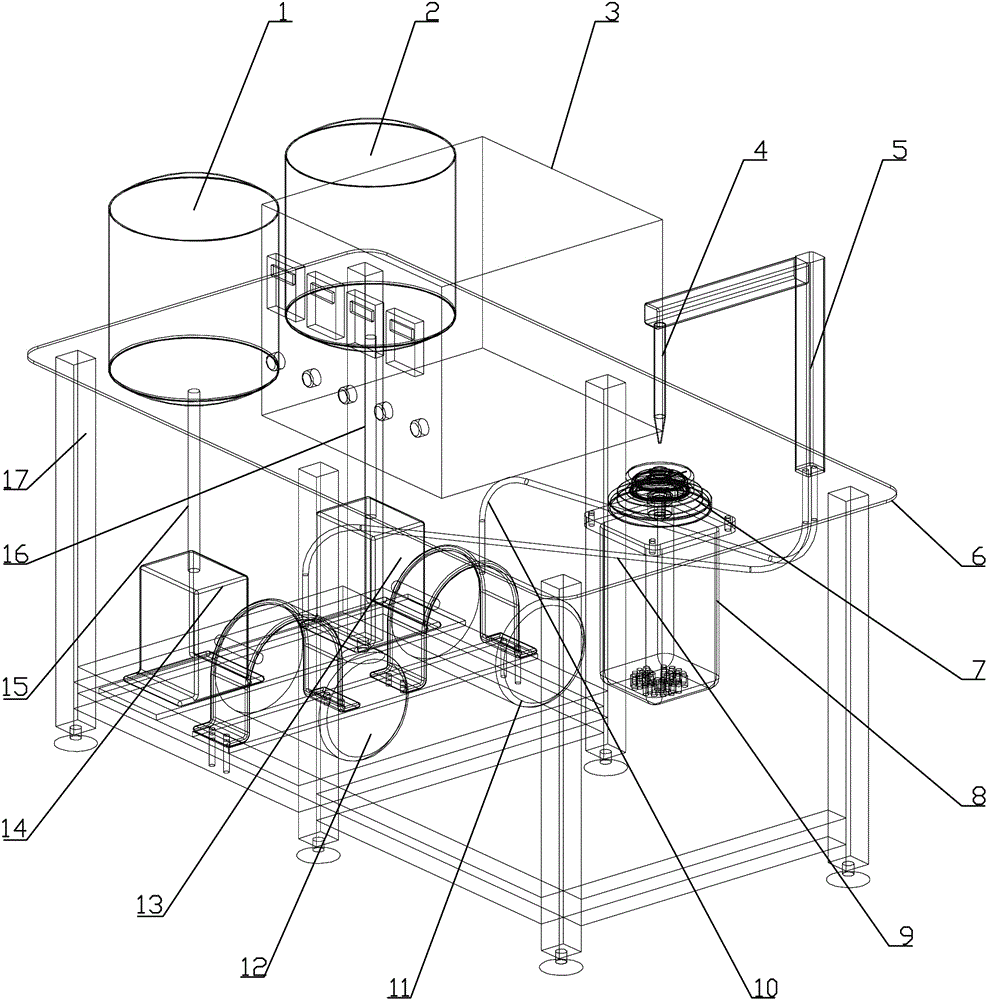

[0033] Such as Figure 1-2 As shown, the automatic glue pouring device for the filter element includes a workbench 6 fixedly installed on the top of the bracket 17, and a No. 1 glue tank 1 and a No. 2 glue tank are installed side by side on the left side of the workbench 6. Tank 2; a control box 3 is installed in the middle of the workbench 6.

[0034] Further, the bottom of the No. 1 plastic tank 1 is connected to the No. 1 buffer tank 14 through the No. 1 rubber inlet pipe 15, and the No. 1 buffer tank 14 is connected to the liquid suction port of the No. 1 vacuum pump 12. The No. 1 vacuum pump The drain port of 12 links to each other with No. 1 rubber outlet pipe 9.

[0035] Further, the bottom of the No. 2 rubber tank 2 is connected to the No. 2 buffer tank 13 through the No. 2 rubber inlet pipe 16, and the No. 2 buffer tank 13 is connected to the liquid suction port of the No. 2 vacuum pump 11. The No. 2 vacuum pump The drain port of 11 links to each other with No. 2 ru...

Embodiment 2

[0044] The tank glue method adopting the automatic glue throwing glue pouring device of the filter element, it comprises the following steps:

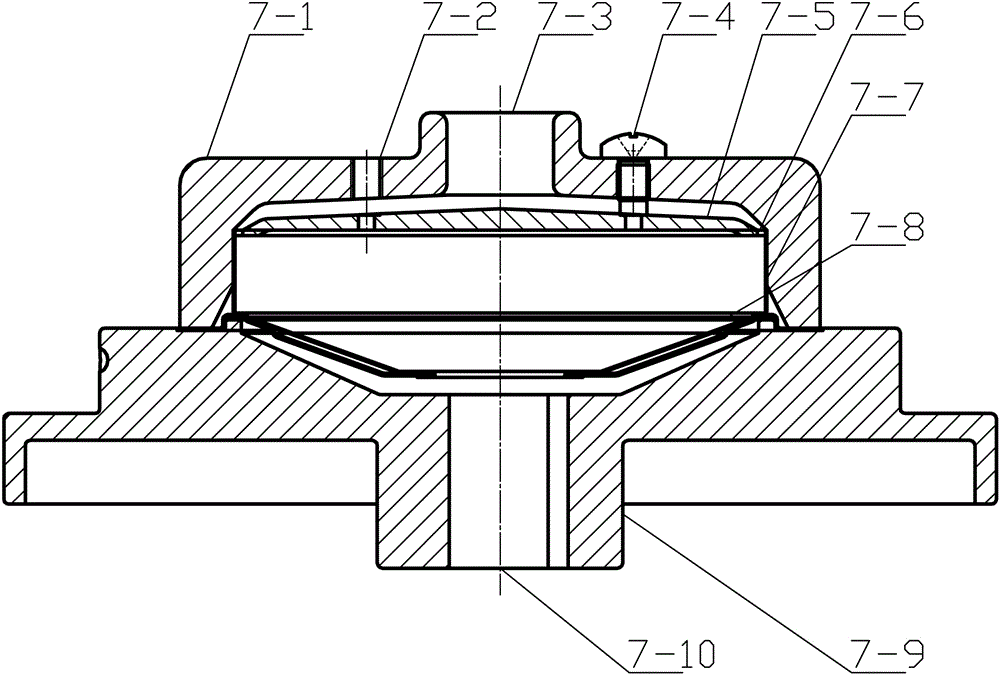

[0045] In the first step, put a certain amount of No. 1 rubber and No. 2 rubber in the No. 1 plastic tank 1 and No. 2 plastic tank 2 respectively, install the filter shell 7-7 on the base 7-9, and place the filter element 7 -8 is installed on the filter shell 7-7, and is fixed by pressing the cover 7-1, and then the whole tank glue fixture 7 is installed on the output shaft of the variable frequency motor 8 through the shaft hole 7-10;

[0046] In the second step, start the No. 1 vacuum pump 12 and the No. 2 vacuum pump 11, so that a certain negative pressure is formed inside the No. 1 buffer tank 14 and No. 2 buffer tank 13, and the No. 1 rubber is sequentially passed through the No. 1 rubber inlet pipe 15, No. 1 buffer tank 14, No. 1 vacuum pump 12, and No. 1 rubber outlet pipe 9 enter the mixer 4; No. No. rubber hose 10 enters mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com