Production technology of high-temperature-resistant blending filter materials

A production process, high temperature resistant technology, applied in filtration separation, dispersed particle filtration, dispersed particle separation and other directions, it can solve the problem of the quality decline of the filter material, and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

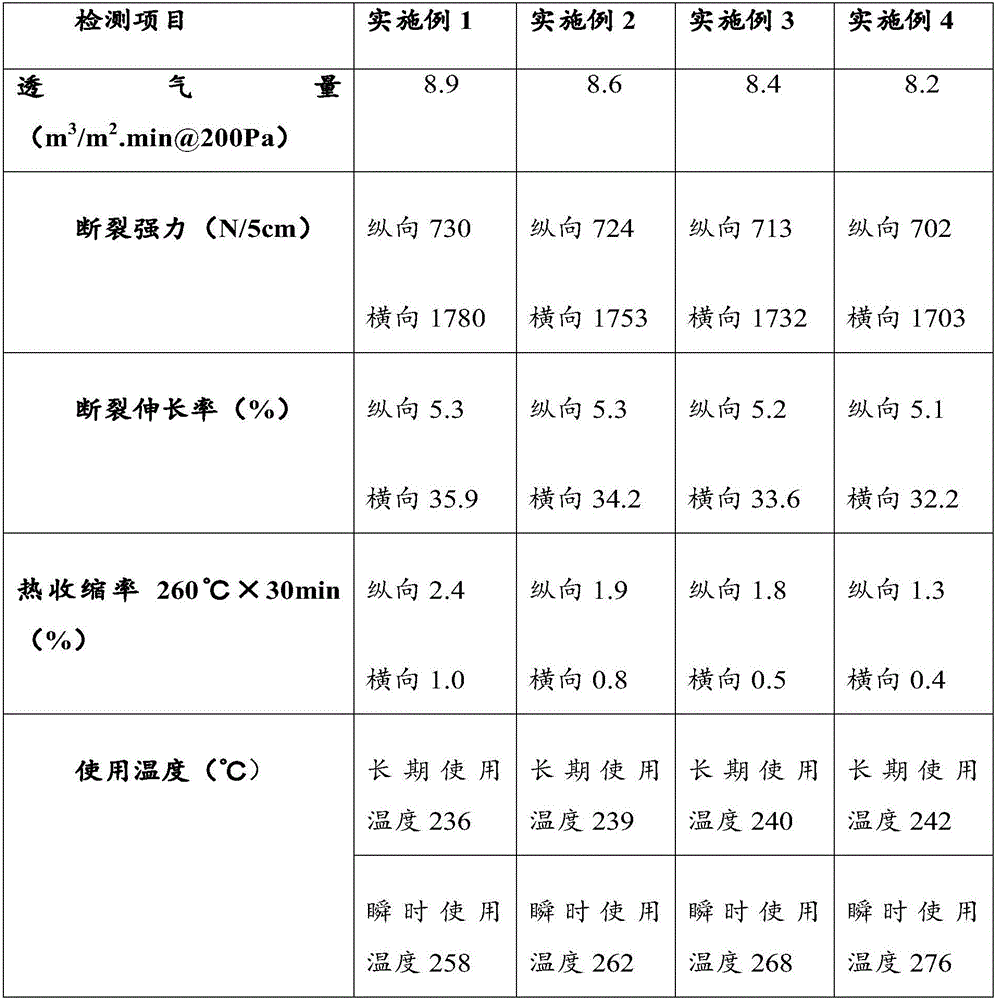

Examples

Embodiment 1

[0016] First mix PTFE with aramid, and then mix with P84, the ratio is P84 (50%), PTFE (20%), aramid (30%), through the DILO pre-spinning production line (including unpacking, pre-opening, large warehouse Cotton blending, fine opening, cotton feeding box, carding machine, web lapper, pre-needling machine, main needling machine, trimming needling) to produce cloth; then through singeing and calendering, this embodiment adopts singeing The calender is a three-roll singeing calender, the temperature of the three rolls (upper, middle and lower) is set at 150°C, 150°C, and 80°C, the speed is 16m / min, the pressure is 0.8MPa, and the singeing burner is High temperature burner, burner flow rate is 3.0Kpa, about 20min for one roll of filter material singeing.

[0017] Stenter setting, PTFE impregnation and heat drying, these three steps are in one production line, the equipment from front to back is stenter setting machine-chemical liquid tank-vertical drying machine, stenter setting c...

Embodiment 2

[0020] First mix PTFE with aramid, and then mix with P84, the ratio is P84 (50%), PTFE (25%), aramid (25%), through the DILO pre-spinning production line (including unpacking, pre-opening, large warehouse Cotton blending, fine opening, cotton feeding box, carding machine, web lapper, pre-needling machine, main needling machine, trimming needling) to produce cloth; then through singeing and calendering, this embodiment adopts singeing The calender is a three-roll singeing calender, the temperature of the three rolls (upper, middle and lower) is set at 150°C, 150°C, and 80°C, the speed is 16m / min, the pressure is 0.8MPa, and the singeing burner is High temperature burner, burner flow rate is 3.0Kpa, about 20min for one roll of filter material singeing.

[0021] Stenter setting, PTFE impregnation and heat drying, these three steps are in one production line, the equipment from front to back is stenter setting machine-chemical liquid tank-vertical drying machine, stenter setting c...

Embodiment 3

[0024] First mix PTFE with aramid, and then mix with P84, the ratio is P84 (50%), PTFE (35%), aramid (15%), through the DILO pre-spinning production line (including unpacking, pre-opening, large warehouse Cotton blending, fine opening, cotton feeding box, carding machine, web lapper, pre-needling machine, main needling machine, trimming needling) to produce cloth; then through singeing and calendering, this embodiment adopts singeing The calender is a three-roll singeing calender, the temperature of the three rolls (upper, middle and lower) is set at 150°C, 150°C, and 80°C, the speed is 16m / min, the pressure is 0.8MPa, and the singeing burner is High temperature burner, burner flow rate is 3.0Kpa, about 20min for one roll of filter material singeing.

[0025] Stenter setting, PTFE impregnation and heat drying, these three steps are in one production line, the equipment from front to back is stenter setting machine-chemical liquid tank-vertical drying machine, stenter setting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com