A double-layer composite hydrogel for repairing osteochondral tissue, preparation method and application

A composite hydrogel, double-layer composite technology, applied in tissue regeneration, prosthesis, medical science and other directions, can solve the problems of poor fracture toughness, poor self-healing performance, inability to simulate double-layer materials, etc., and achieves a simple preparation method. , the effect of reducing work intensity and good repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a preparation method for the above-mentioned SA / Aker / GDL and SA / AG double-layer composite hydrogel, comprising the following steps:

[0049] Step 1. Mix the agarose solution heated to a liquid state with the sodium alginate solution in a certain proportion for use;

[0050] Step 2, sodium alginate, feldspar, and gluconolactone are formulated into a mixed solution in a certain proportion for use;

[0051] Step 3. Add the agarose solution / sodium alginate mixed solution of step 1 into the mold and let it stand to condense to form a SA / AG composite hydrogel, and add the sodium alginate / magnesia feldspar / gluconolactone mixed solution of step 2 into the mold On the top of the formed SA / AG composite hydrogel, continue to stand and condense to obtain a double-layer composite hydrogel.

[0052] Further, in the preparation method of the double-layer composite hydrogel, the mass volume percentage (g / ml) of agarose and sodium alginate in step 1 ...

Embodiment 1

[0069] The preparation of embodiment 1.SA / Aker / GDL and SA / AG bilayer composite hydrogel

[0070] Step 1. Dissolve 2 g of sodium alginate powder in 100 mL of deionized water and keep stirring to prepare a 2% medium viscosity sodium alginate solution. Prepare the agarose solution heated to a liquid state as a solution with a mass volume (g / ml) percentage of 2%, and mix it with the sodium alginate solution at a volume ratio of 1:1 to obtain a mixed solution of sodium alginate and agarose for use;

[0071] Step 2. Grinding and mixing 2% SA solution with 2% Aker powder by mass volume (g / ml) percentage, then adding GDL powder with 2% mass volume (g / ml) percentage, and mixing evenly to prepare seaweed Sodium phosphate, feldspar, gluconolactone mass volume (gram / ml) percentage is the mixed solution of 2% stand-by;

[0072] Step 3. Take about 500 μL of the mixed solution of sodium alginate and agarose in step 1 and add it to the mold and let it stand to condense to form a SA / AG compos...

Embodiment 2

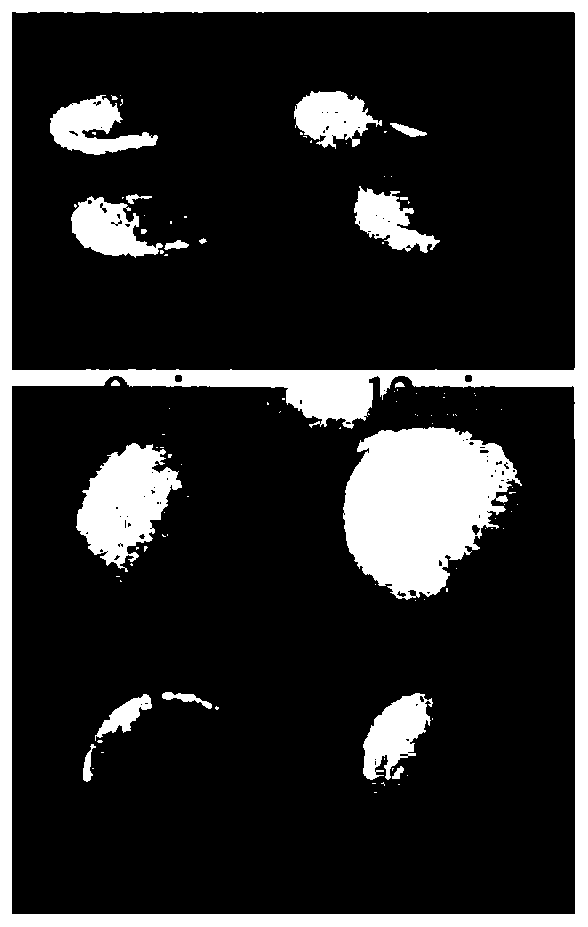

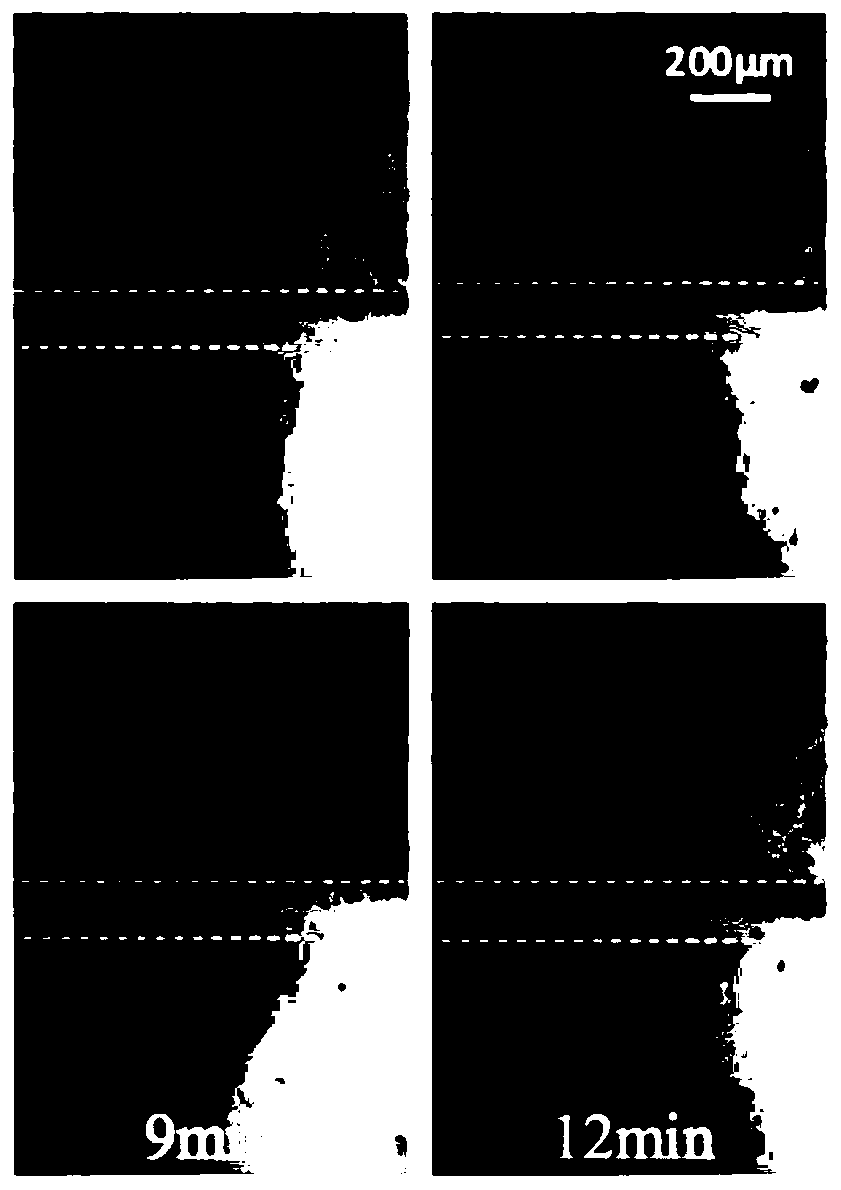

[0074] Example 2.Appearance and microstructure analysis of SA / Aker / GDL and SA / AG bilayer composite hydrogel

[0075] The SA / Aker / GDL and SA / AG double-layer hydrogels prepared in Example 1 were freeze-dried, and the hydrogels and their connection interfaces were observed with an optical microscope.

[0076] Such as figure 2 As shown, the SA / AG layer and the SA / Aker / GDL layer of the bilayer composite hydrogel have a tightly bonded connection interface, and the connection transition between the bilayer composite hydrogel is natural.

[0077] The SA / Aker / GDL and SA / AG double-layer hydrogel prepared in Example 1 were freeze-dried, and the dried double-layer composite hydrogel sample was cut to obtain a relatively flat internal cross section. Scanning electron microscopy (SEM) was used to observe the cross-sectional structure of the bilayer hydrogel junction at an accelerating voltage of 10kV.

[0078] as attached image 3 As shown, the left side is the SA / AG layer of the double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com