Cigarette firmware material meeting safety requirements and application thereof

A firmware and technology for cigarettes, applied in applications, tobacco, smoke oil filter elements, etc., can solve problems such as insufficient tightness of the guide tube, low consumer quality, and reduced filtration efficiency, so as to improve the appearance and eliminate radial separation. The effect of equal force and filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

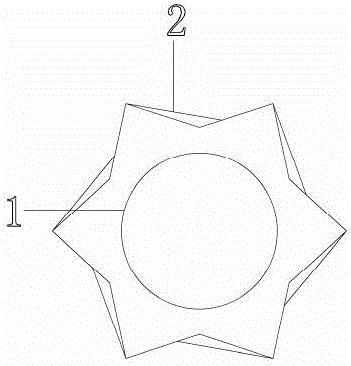

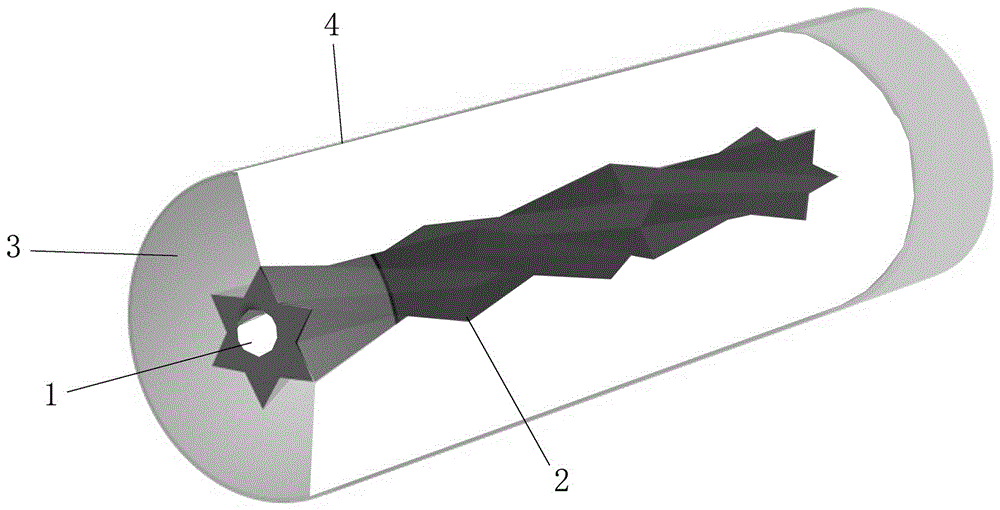

[0040] Such as figure 1 —4 and Figure 8 As shown in the present embodiment, a solid material for cigarettes that meets the safety requirements is hollow as a whole, a spiral conduit that rotates around the geometric center of the radial section, and includes a conduit body 1 and peripheral structures. The conduit The length of the body 1, the number of helical turns per unit length and the inner diameter are determined according to the actual needs of the product; the peripheral structure includes the helical twill 2 provided on the outer wall surface of the catheter body 1, the inclination angle of the helical twill 2 and the number of helical turns per unit length are the same as those of the catheter The main body 1 is consistent; the raw material weight percentage of the firmware material for cigarettes is linear low density polyethylene (LLDPE-LL1002KW): low density polyethylene (LDPE-FD0474 Basel 1840H) = 9:1, linear low density polyethylene is linear The material is e...

Embodiment 2

[0051] Such as Figure 5 and Figure 8 As shown, the structure, formula and manufacturing method of the firmware material for cigarettes described in this embodiment that meet the safety requirements are basically the same as those described in Embodiment 1, the difference is that the wall thickness of the conduit body is 0.5 mm, and the spiral twill 2 has a height of 1mm.

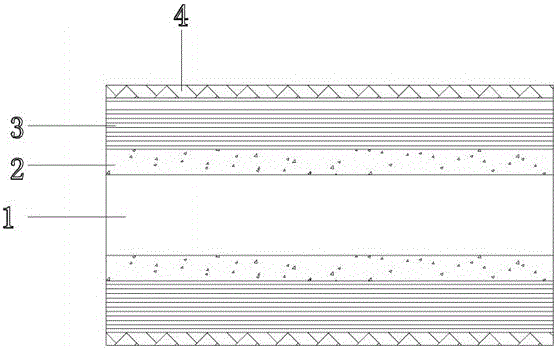

[0052] For the application of the tobacco firmware material in cigarette filter rods, a section of the above-mentioned tobacco firmware material shorter than the tow 3 and located inside the tow 3 is arranged in the filter rod tow 3 to obtain a composite filter rod.

Embodiment 3

[0054] Such as Figure 6 and Figure 8 As shown, the structure, formula and manufacturing method of the firmware material for cigarettes described in this embodiment that meet the safety requirements are basically the same as those described in Embodiment 1, the difference is that the wall thickness of the conduit body is 1.5mm, and the spiral twill The height of 2 is 1 mm; and the solid material for smoking is prepared after adding fat-soluble fragrance to the raw material of the solid material for smoking, so that the aroma is released slowly during use.

[0055] For the application of the tobacco firmware material in cigarette filter rods, a section of the tobacco firmware material shorter than the tow 3 and positioned at the front end of the tow 3 is arranged in the filter rod tow 3 to obtain a composite fragrance-embedding filter rod.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com