Method for producing urchin-like nano TixSn1-xO2/graphene three-dimensional composite material and application of composite material on negative electrode of lithium ion battery

A composite material, tixsn1-xo2 technology, applied in the field of nanomaterials science and secondary power supply, can solve the problems of poor electronic conductivity and low theoretical capacity, and achieve the effects of abundant raw materials, simple principle and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

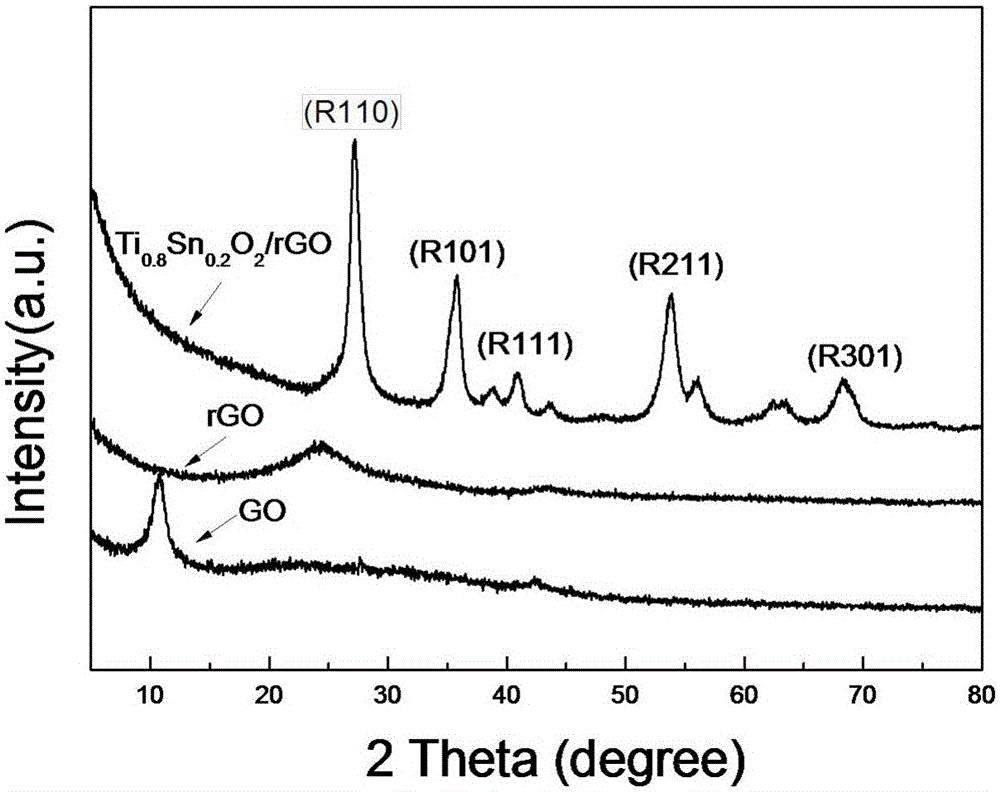

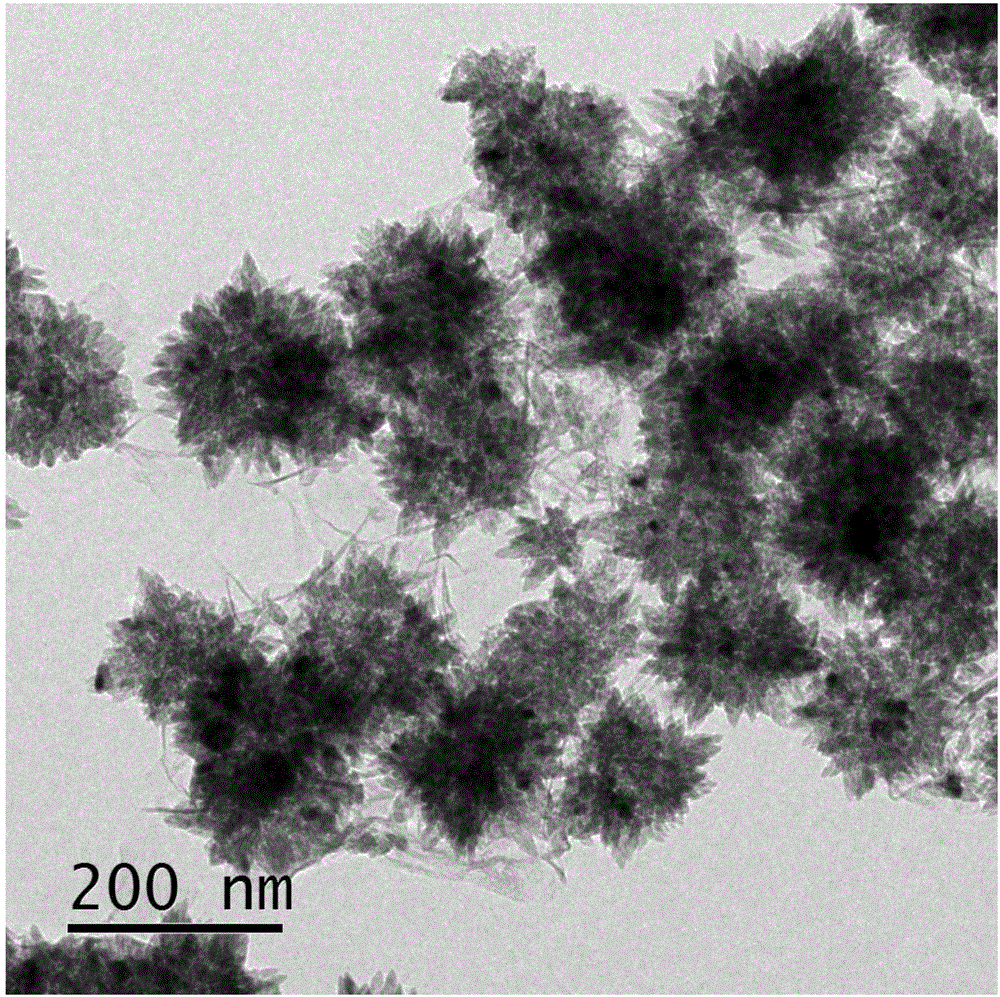

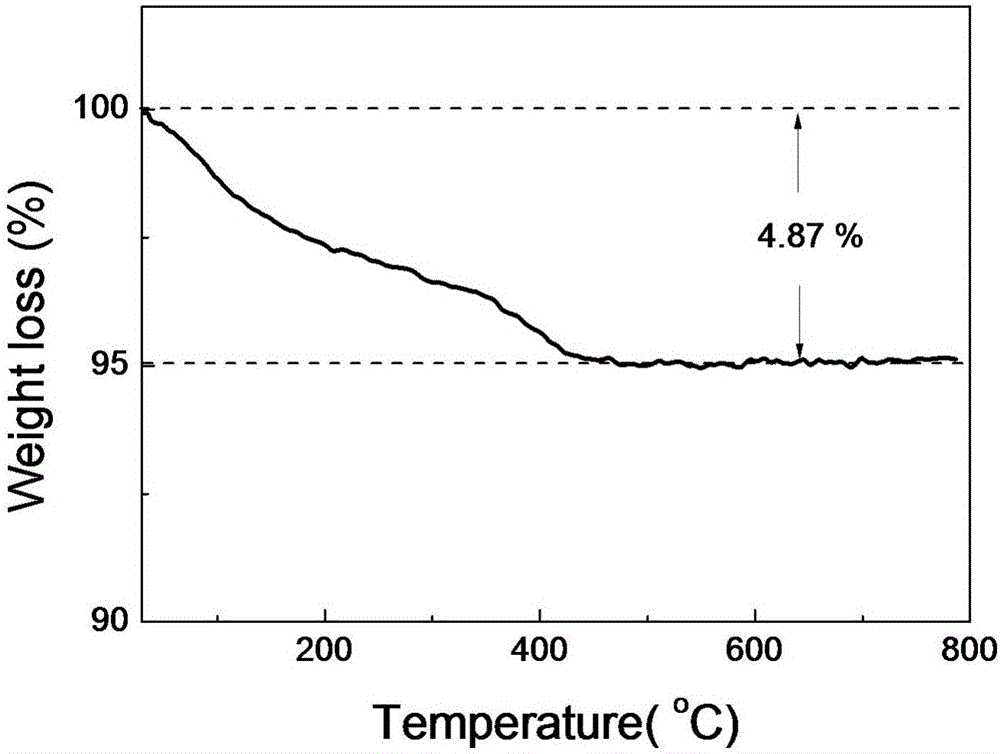

[0030] A kind of sea urchin-like nano-Ti x sn 1-x o 2 The preparation method of / graphene three-dimensional composite material comprises the steps:

[0031] (1) Use the improved Hummers method to prepare graphene oxide, take a dry and clean container, add 70ml of concentrated sulfuric acid with a concentration of 98%, put the container in ice water and ice bath; weigh 2g of flake graphite and add it to the ice water bath concentrated sulfuric acid solution, and then mechanically stirred for 20 to 30 minutes; weigh 8g of potassium permanganate and slowly add it to the above solution, as slowly as possible, until the solution turns green and the potassium permanganate is completely added Finally, ice bath for another two hours; then move to a constant temperature water bath at 35°C and stir at a constant speed for 12 hours, turning into a thick yellow-brown slurry; remove the container from the water bath, and divide it into 6 times under stirring, each time Add 46ml of water ...

Embodiment 2

[0036] A kind of sea urchin-like nano-Ti x sn 1-x o 2 The preparation method of / graphene three-dimensional composite material comprises the steps:

[0037] (1) Use the improved Hummers method to prepare graphene oxide, take a dry and clean container, add 60ml of concentrated sulfuric acid with a concentration of 98%, put the container in ice water for an ice bath; weigh 1.5g of flake graphite and add it to the frozen In the concentrated sulfuric acid solution in the water bath, then carry out mechanical stirring for 20-30min; weigh 8g of potassium permanganate and slowly add it to the above solution, as slow as possible when adding, until the solution turns green and the potassium permanganate is completely added. After that, put it in ice bath for another two hours; then move it to a constant temperature water bath at 35°C and stir at a constant speed for 12 hours to form a thick yellow-brown slurry; remove the container from the water bath, and divide it into 6 times under...

Embodiment 3

[0042] A kind of sea urchin-like nano-Ti x sn 1-x o 2 The preparation method of / graphene three-dimensional composite material comprises the steps:

[0043] (1) Prepare graphene oxide by the improved Hummers method, take a dry and clean container, add 70ml of concentrated sulfuric acid with a concentration of 98%, put the container in ice water for an ice bath; weigh 1.5g of flake graphite and add it to the ice In the concentrated sulfuric acid solution in the water bath, then carry out mechanical stirring for 20-30min; weigh 8g of potassium permanganate and slowly add it to the above solution, as slow as possible when adding, until the solution turns green and the potassium permanganate is completely added. After that, put it in ice bath for another two hours; then move it to a constant temperature water bath at 35°C and stir at a constant speed for 12 hours to form a thick yellow-brown slurry; remove the container from the water bath, and divide it into 6 times under stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com