Epitaxial wafer production process for power chip

A production process and power chip technology, applied in the field of epitaxial wafer production process for power chips, can solve the problems of poor thickness uniformity and resistivity uniformity of silicon epitaxial wafers, solid-state diffusion of substrate impurities, and uneven thermal field distribution, etc. Effects of good growth interface, elimination of solid state diffusion and natural doping phenomena, good thickness uniformity and resistivity uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

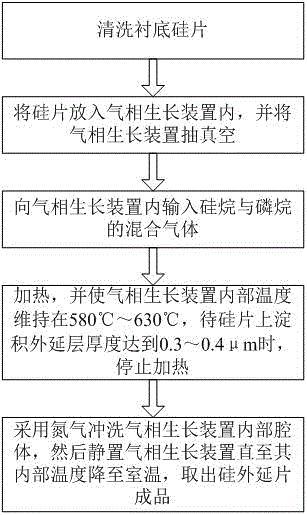

[0041] Such as figure 1 As shown, a production process of epitaxial wafers for power chips includes the following steps: step 1, cleaning the substrate silicon wafer; step 2, putting the cleaned silicon wafer into a vapor phase growth device, and vacuumizing the vapor phase growth device; Step 3, input the mixed gas of silane and phosphine into the vapor phase growth device; Step 4, heat, and keep the internal temperature of the vapor phase growth device at 580°C-630°C, until the thickness of the epitaxial layer deposited on the silicon wafer reaches 0.3-0.4 μm, stop heating; step 5, use nitrogen to flush the internal cavity of the vapor phase growth device to ensure that there is no reaction gas in the internal cavity of the vapor phase growth device, then let the vapor phase growth device stand until the internal temperature drops to room temperature, and take out the silicon epitaxial wafer finished product. In the specific implementation of this embodiment, the vacuum deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com