Digital micromirror-based large dynamic laser far-field focal spot measurement system and measurement method

A digital micromirror and far-field focal spot technology, applied in the field of optics, can solve problems such as inapplicability to irregular focal spot measurement and cumbersome debugging work, so as to realize automatic monitoring and adjustment, improve stability and flexibility, and reduce debugging The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

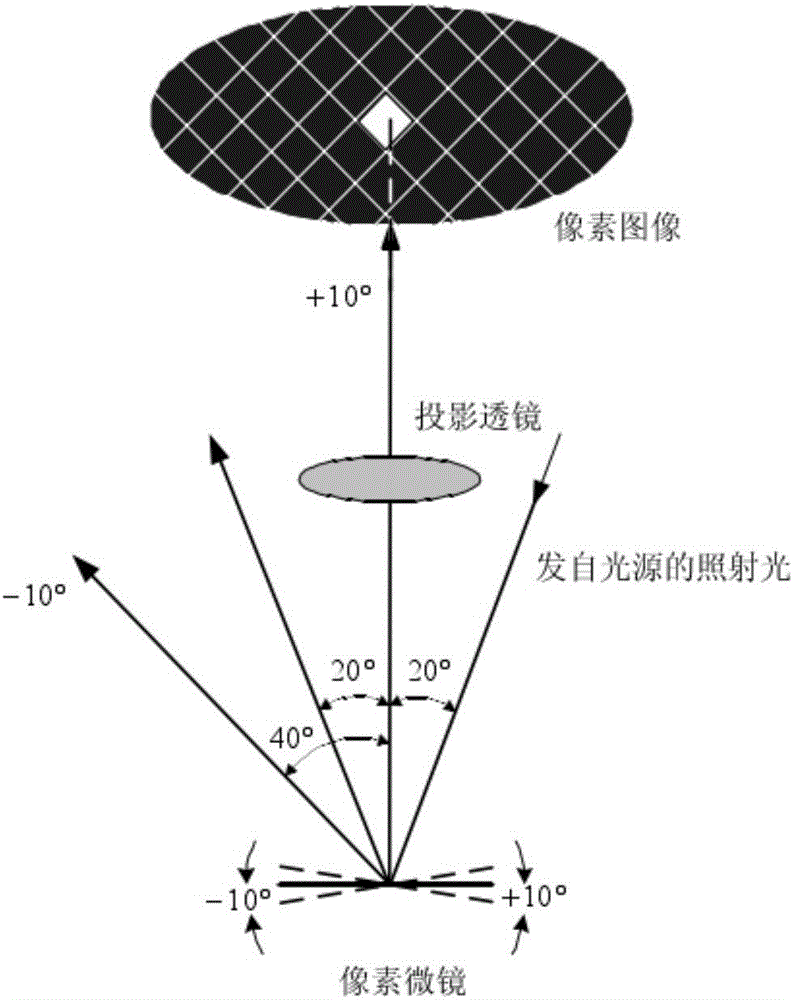

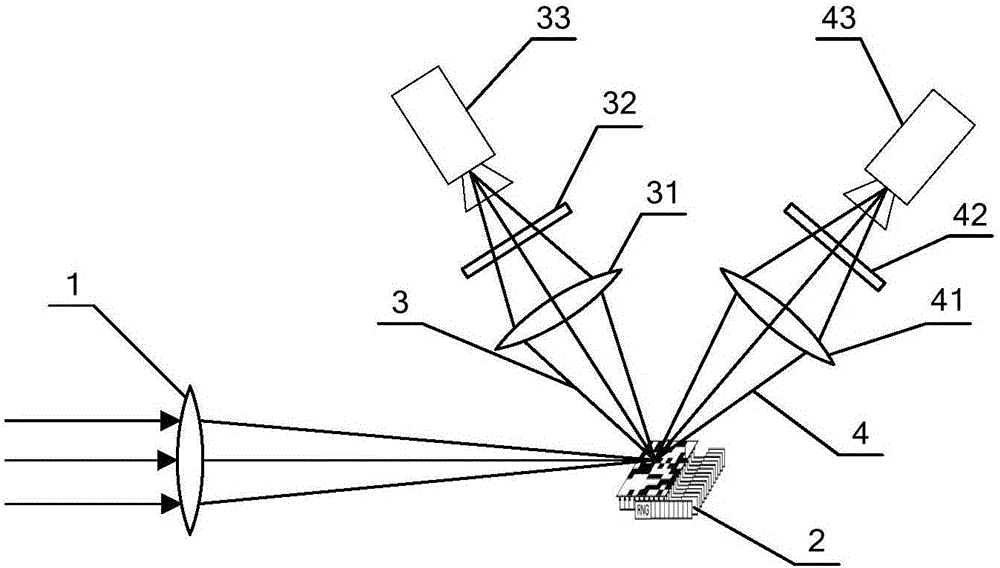

[0020] DMD digital micromirror is a chip-level beam control device produced by TI company in the United States. It controls the beam by controlling the flip state of the micromirror. DMD has been widely used in digital projection, compressed sensing and other fields. The far-field focal spot is imaged to the DMD mirror through the imaging system, and the flipping state of the micro-mirror is controlled by coding, so that the main lobe light path is reflected to one path, and the side lobe light path is reflected to the other path, and the focal spot information of the two paths is captured by two CCD cameras respectively. Receive to obtain the main lobe and side lobe focal spot images, and stitch the two images to obtain a high dynamic far-field focal spot image. Compared with the occlusion ball, through the software control of the flip posture of each micro-mirror of the DMD, the DMD can make corresponding adjustments for the drift of the focal spot position and the specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com