Transmission belt

A technology of transmission belt and rubber layer, applied in the field of transmission belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0025] The transmission belt of the present invention is a V-ribbed belt as an example, but is not limited thereto, and may also be a synchronous belt or a V-belt.

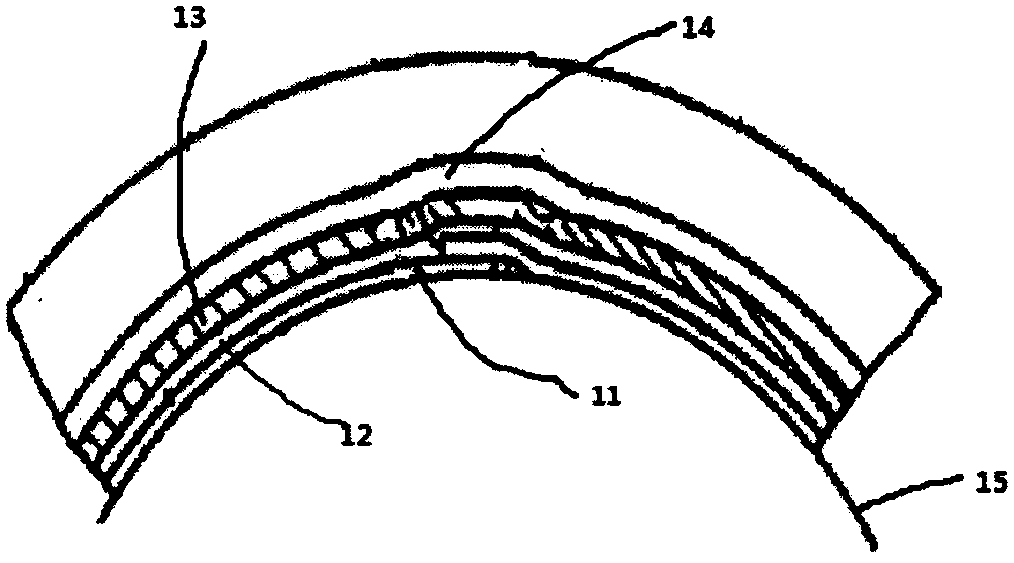

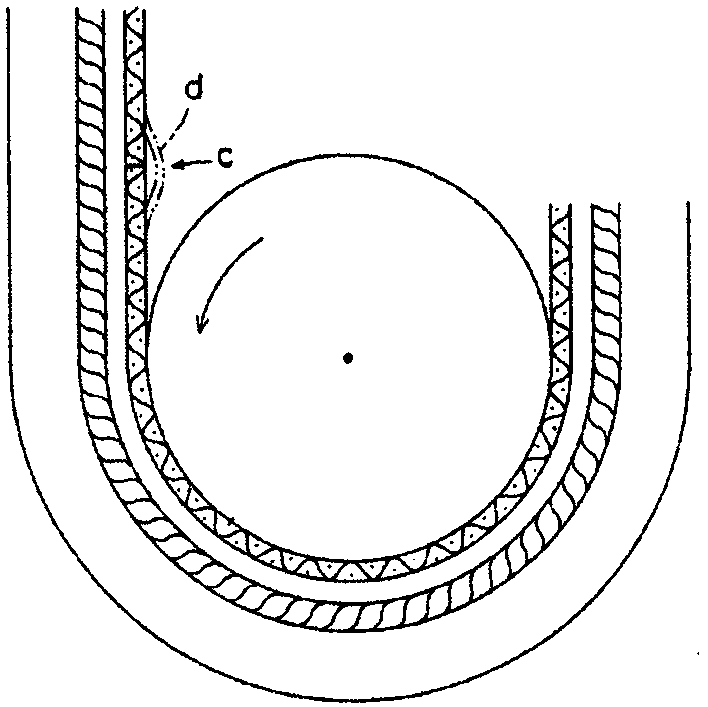

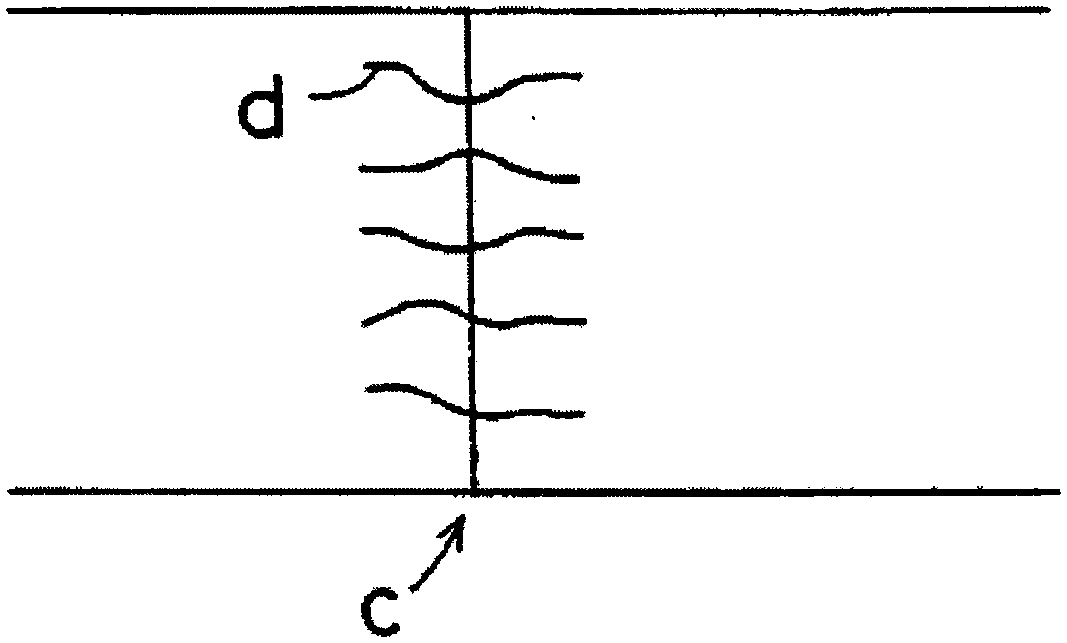

[0026] like Figure 4 The V-ribbed belt shown includes a bottom rubber layer 1, an adhesive rubber layer 5, a tensile cord 2 embedded in the adhesive rubber layer, and a back fabric layer 4 bonded to the back of the adhesive rubber layer 5, as in image 3 As shown, the fabric layer has a butt joint c sewn with stitches d, and the bottom rubber layer 1 has at least one rib extending along the length of the drive belt.

[0027] The bottom rubber layer and the rubber adhering to the rubber layer can be made of the same rubber or different rubbers. It is made by mixing several kinds of rubbers, and it can also include other kinds of rubbers. Fibers to improve strength or water absor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com