The spray painting method of the desk

A technology for desks and paints, applied in spray booths, spray devices, devices for coating liquids on surfaces, etc., can solve problems such as affecting the working environment and paint easily floating around.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

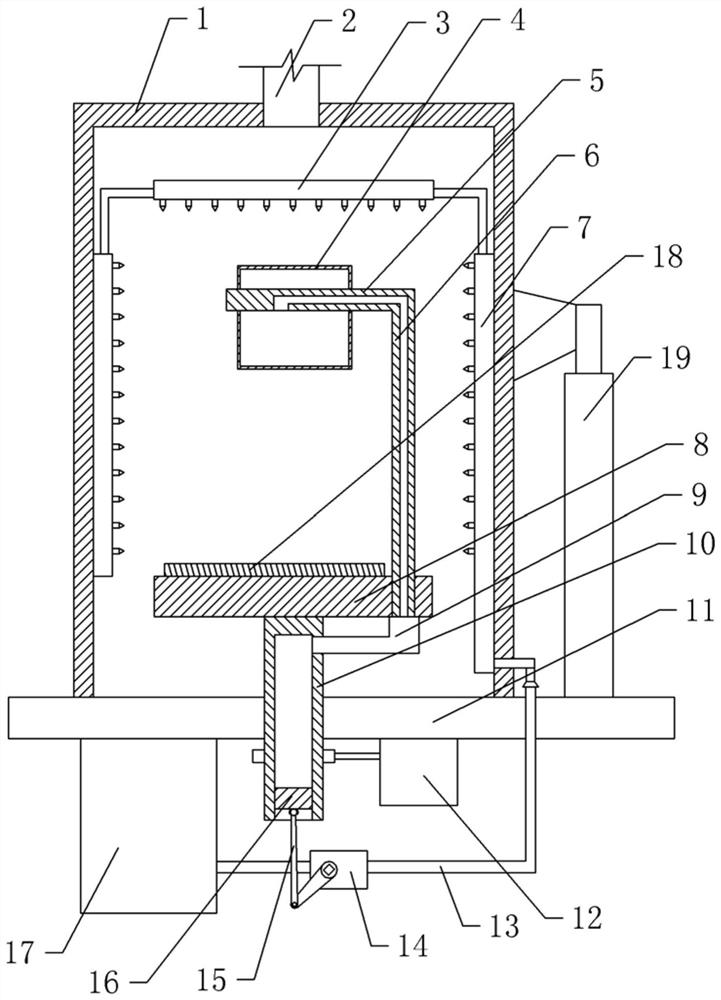

[0020] Embodiment: the spray painting method of desk, utilizes a kind of spray paint device, as figure 1 As shown, the painting device includes a bracket, on which a horizontal support plate 11 is welded, on which a vertical shaft 10 is rotatably connected, and a motor 12 is fixedly installed on the bracket, and the lower end of the motor 12 and the shaft 10 is passed through a worm gear Mechanism connection, the worm wheel of the worm gear mechanism is connected with the lower flat key of the rotating shaft 10, and the worm is fixedly connected with the output shaft of the motor 12 coaxially. The lower part of the rotating shaft 10 is provided with a cavity extending in the axial direction, and a sliding block 16 is sealed and slidably connected in the cavity. The upper end of the rotating shaft 10 is coaxially welded with a horizontal turntable 8. The top of the turntable 8 is provided with a supporting plate 18. The top of the turntable 8 is horizontally provided with three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com