A combined die

A combined die technology, applied in the field of combined dies, can solve problems such as die hole deformation, die waste, and increase production costs, and achieve the effects of avoiding unsmooth production, reducing production costs, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

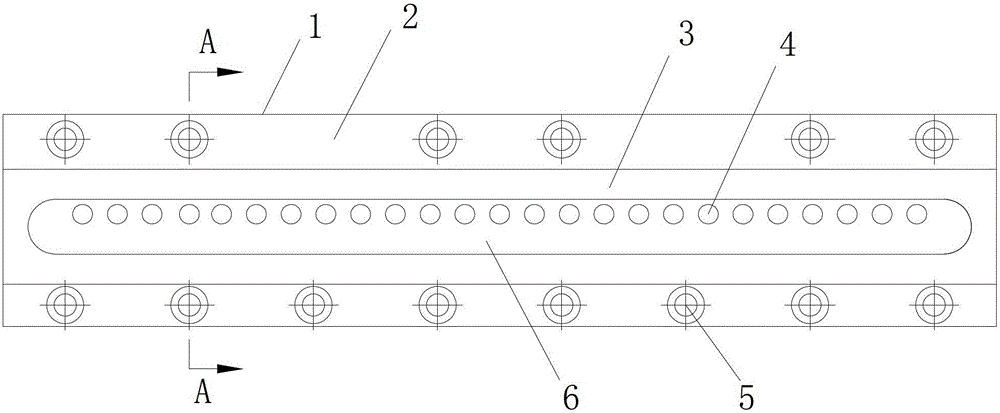

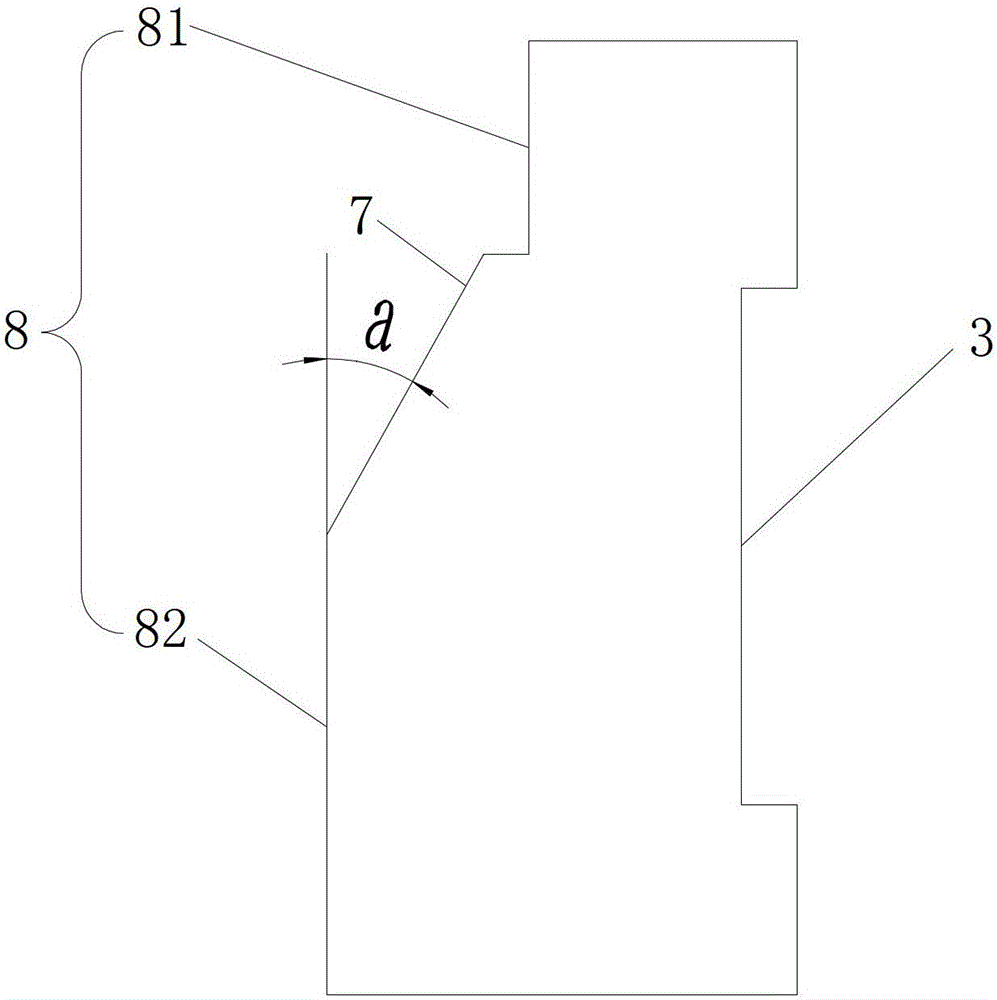

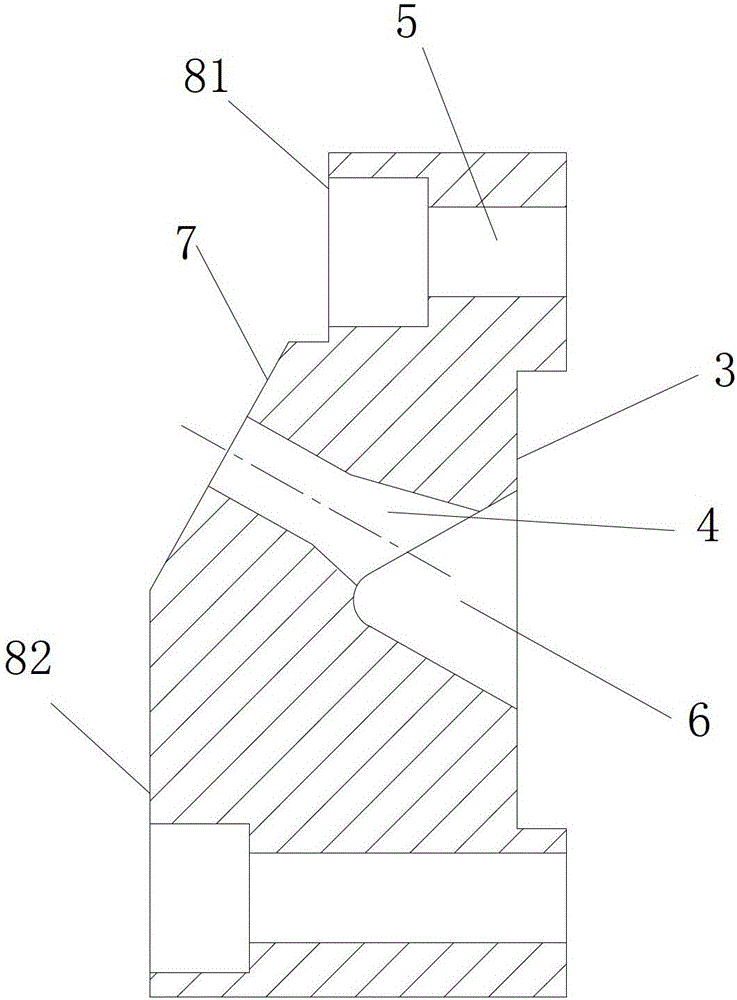

[0023] like Figure 1 to Figure 4 A combined die shown includes a die main body 1, the feed side end face 2 of the die die main body 1 is connected to the extruder head, and the feed side end face 2 is provided with a connecting groove 3, the A through hole 4 is provided at the bottom of the connecting groove 3 , and a die hole liner 9 matching the size of the through hole 4 is fixedly installed in the through hole 4 . The combined die of this embodiment is applied to a twin-screw extruder.

[0024] As a preference, the die hole liner 9 is fixedly installed in the through hole 4 through interference fit. The fixed installation method of interference fit can facilitate the installation or removal of the die hole liner 9 .

[0025] As a preference, the die hole liner 9 includes a cylindrical ejection section 91 and a trumpet-shaped feed section 92, and the die hole diameter of the feed section 92 is greater than the die hole diameter of the ejection section 91, and The feedin...

Embodiment 2

[0035] This combined die is the same as embodiment 1 except the following features: the size of the included angle a is 45°.

Embodiment 3

[0037] This combined die is the same as embodiment 1 except the following features: the size of the included angle a is 75°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com