Telescopic movable bridge and using method

A telescoping, abutment technology applied to open bridges. It can solve problems such as bridge opening restrictions, traffic impact, poor adaptability to water level changes, etc., and achieve the effect of simplifying the structure and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

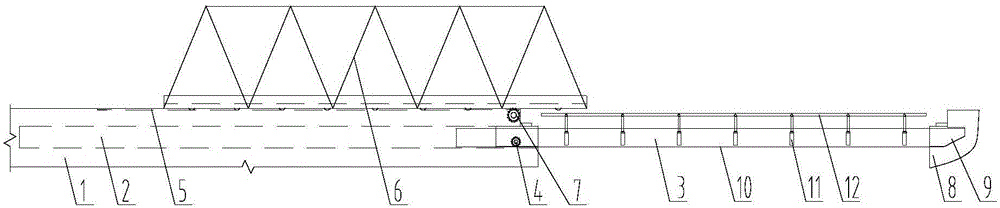

[0023] Embodiment 1, see attached figure 1 , a telescopic opening bridge, which includes: left abutment 1, guide beam slideway 2, guide beam 3, guide beam propulsion mechanism 4, fixed slideway 5, bridge span 6, push bridge mechanism 7, right abutment 8 , hydraulic system, electrical system;

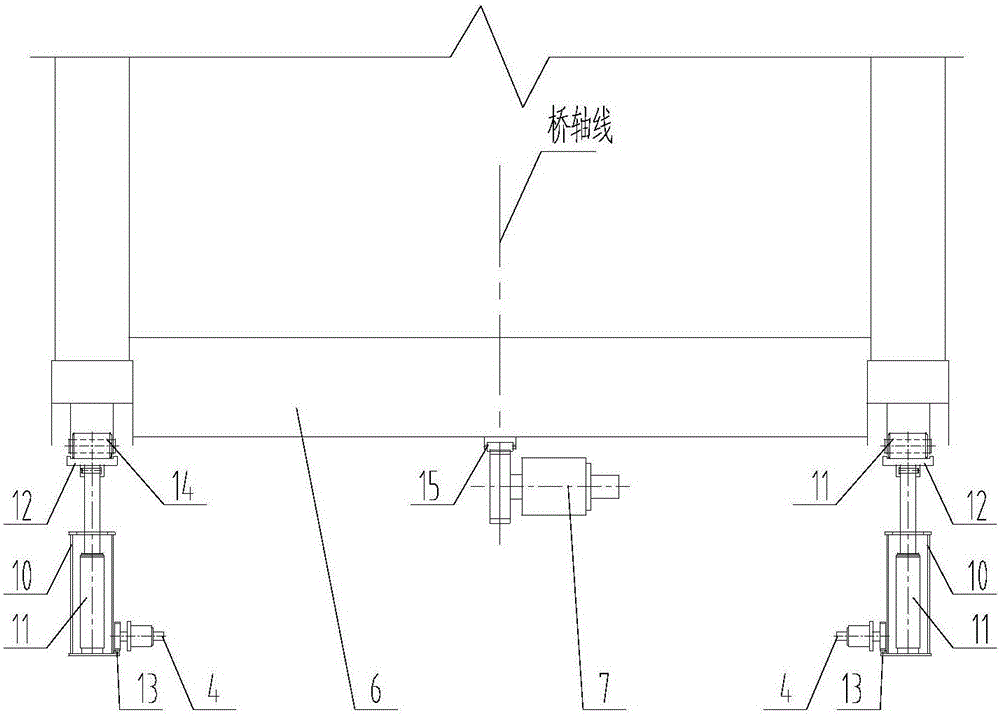

[0024] See attached figure 2 , 3 , two sets of fixed slideways 5 are symmetrically arranged on the upper surface of the left abutment 1 along the bridge axis; the bridge pushing mechanism 7 is installed on the front end of the left abutment 1 along the bridge axis; two sets of guide beam slideways 2 are symmetrically installed on the fixed Inside the left abutment 1 below the slideway 5; two sets of guide beams 3 are symmetrically installed in the guide beam slideways 2 along the bridge axis, and two sets of guide beam propulsion mechanisms 4 are respectively fixedly installed on the front ends of the two sets of guide beam slideways 2; Two sets of guide beam bearings 9 are arranged ...

Embodiment 2

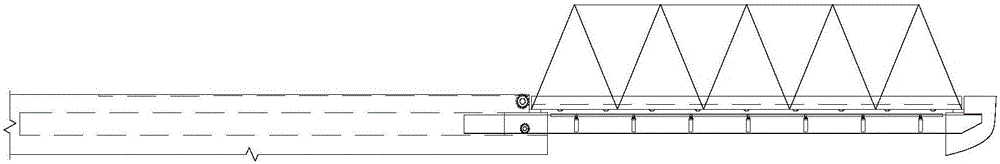

[0028] Embodiment 2: see attached Figure 4-8 , a telescopic opening bridge using method, it uses a kind of telescopic opening bridge as described in embodiment 1, comprises the following steps:

[0029] A. The bridge opens

[0030] The guide beam 3 is driven by the guide beam propulsion mechanism 4 to reach the guide beam support 9 of the right abutment 8 and is in place, and the lifting cylinder 11 stretches out to lift the lifting slideway 12 and the bridge span 6. At this time, the lifting slideway 12 and the fixed The slideway 5 is located on the same plane, and the second pin gear of the push bridge mechanism 7 is stretched out to mesh with the second pin tooth 15, and the drive bridge span 6 is moved from the lifting slideway 12 to the fixed slideway 5, and the lifting cylinder 11 is retracted. Put the lifting slideway 12 back into place, and the guide beam propulsion mechanism 4 drives the guide beam 3 to retract into the guide beam slideway 2 and put it in place, com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com