Steel-rubber concrete fastener type combined box beam

A technology of rubber concrete and combination box, applied in the direction of bridges, building components, bridge materials, etc., can solve the problems of poor crack resistance, bending resistance and impact performance, inconvenient connection construction, troublesome connection, etc., to shorten the construction period, The effect of convenient factory processing and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

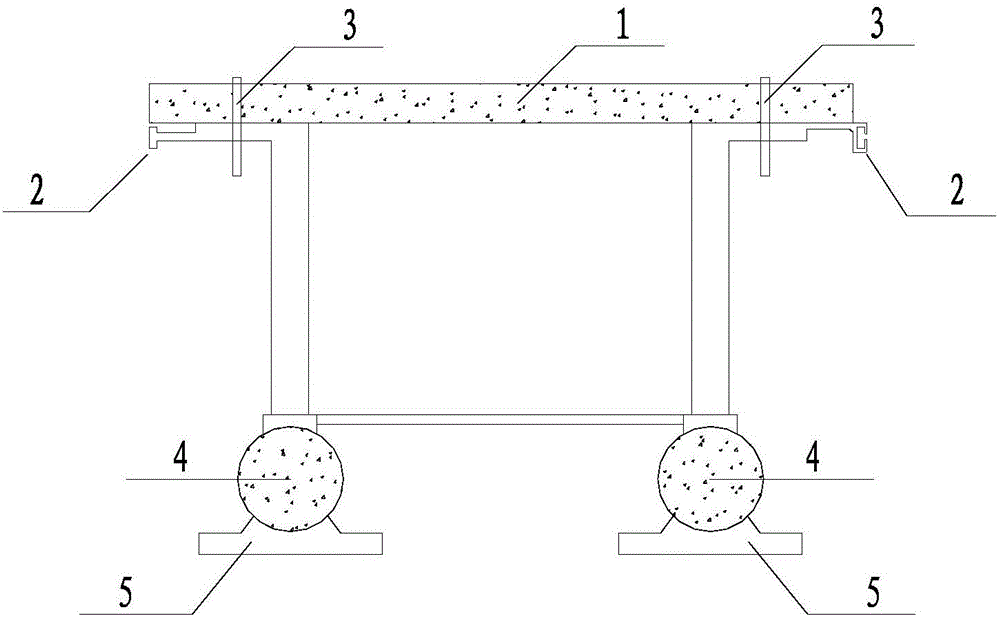

[0023] refer to figure 1 , a steel-rubber concrete fastener type composite box girder, comprising a top plate and a bottom plate arranged below the top plate, two ends between the top plate and the bottom plate are provided with shaped steel webs, characterized in that: the top plate Made of rubber concrete material; the two ends of the top plate are provided with fastener-type connectors for horizontal connection, the steel web and the top plate are connected by bolts, and the bottom of the bottom plate is provided with a circular steel pipe The rubber concrete beam, the bottom of the circular steel pipe rubber concrete beam is provided with a shelving device;

[0024] Both the bottom of the bottom plate and the upper end of the shelving device have curved surfaces matching the surface of the circular steel pipe rubber concrete beam, and the lower end of the shelving device is a plane.

[0025] The shaped steel web has an L-shaped structure, one side of the L-shaped structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com