Rapid preparing method of black titanium dioxide nanotube array

A technology of black titanium dioxide and nanotube arrays, applied in the direction of nanotechnology, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of reduced specific surface area, poor safety, slow speed, etc., and achieve accurate and detailed data, firm combination, and process advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with accompanying drawing:

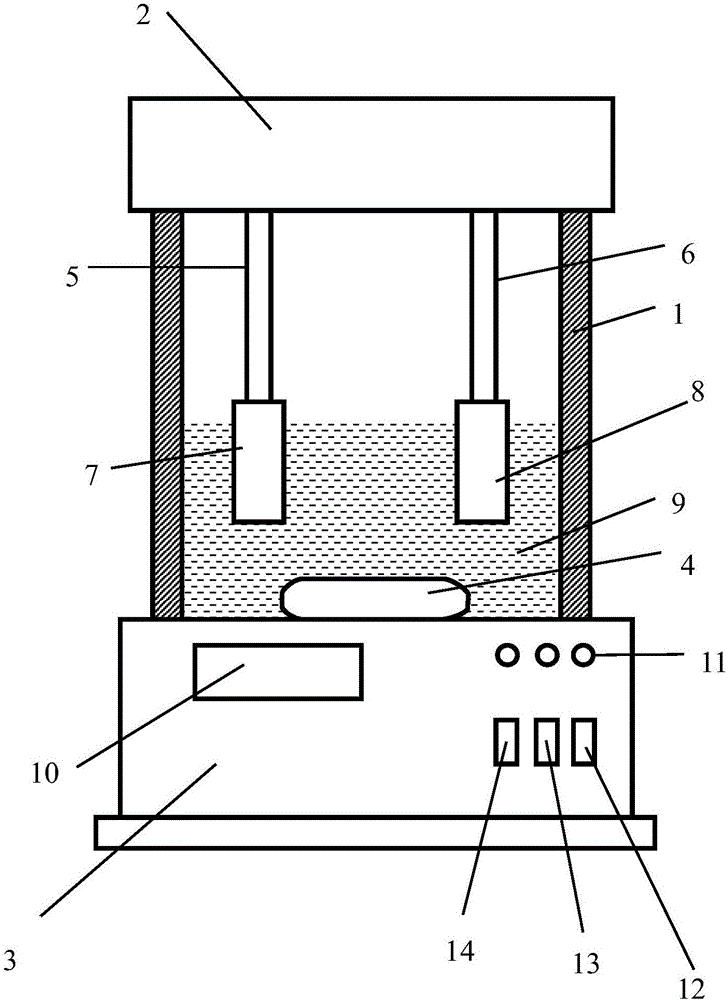

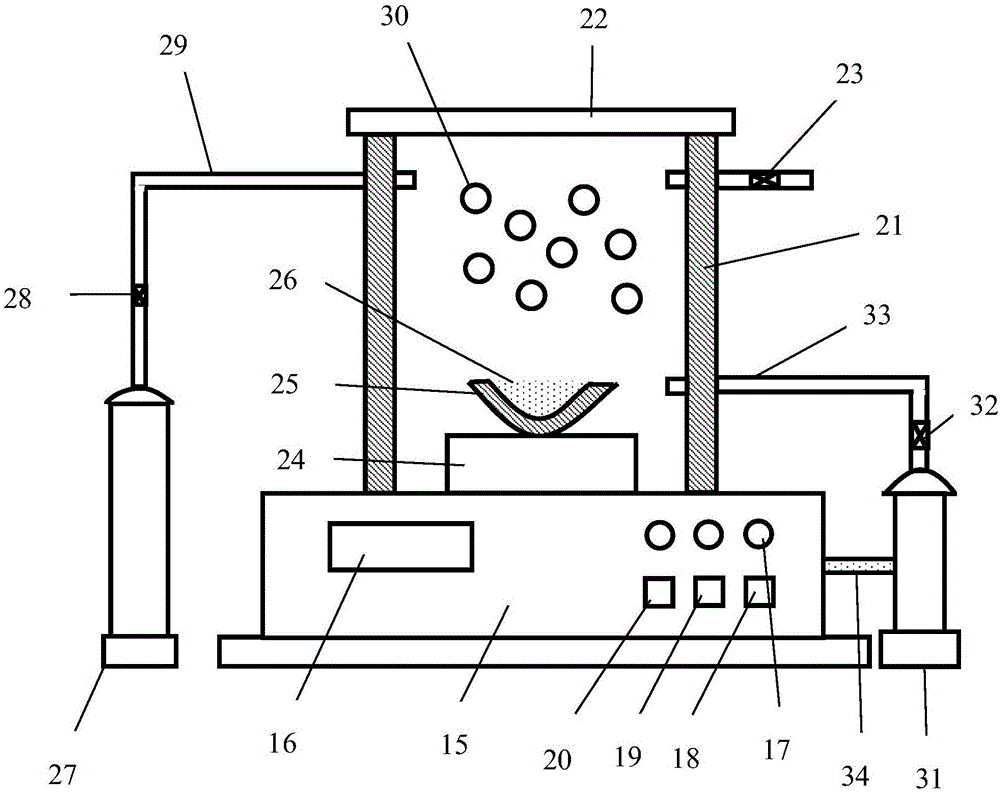

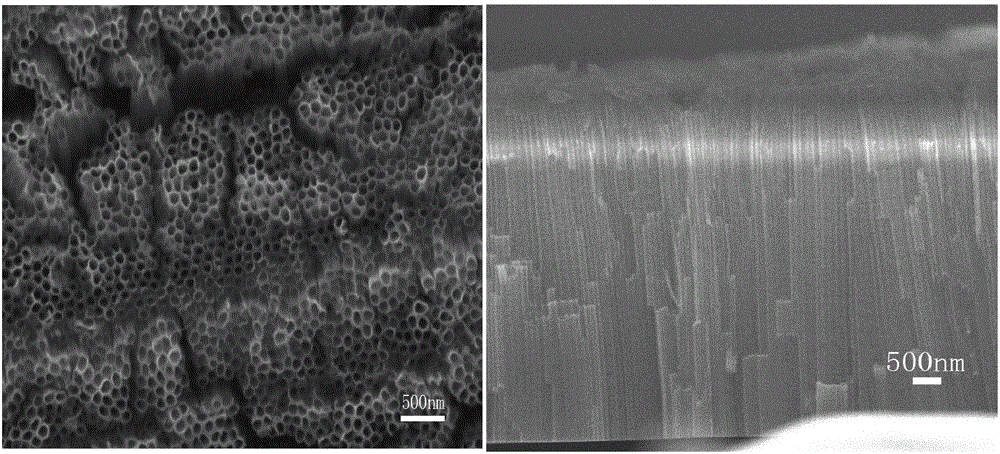

[0072] figure 1 As shown, in order to prepare the electrolytic state diagram of the titanium dioxide nanotube array, the position and connection relationship of each part must be correct, the ratio should be adjusted, and the operation should be performed in sequence.

[0073] Quantities of chemicals used in preparation are determined in pre-set ranges in grams, milliliters, millimeters, centimeters 3 is the unit of measurement.

[0074] The preparation of titanium dioxide nanotube arrays is carried out in a beaker, in the electrolyte of ethylene glycol, ammonium fluoride, and deionized water, with titanium sheets as anodes and platinum sheets as cathodes. During the sub-stirring process, an array of titanium dioxide nanotubes is generated on the titanium sheet;

[0075] The electrolytic cell 1 is a rectangular glass body, the upper part of the electrolytic cell 1 is a D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com