Black ginseng liquor using decocted black ginseng and manufacturing method thereof

A manufacturing method and technology of black ginseng, applied in the preparation of alcoholic beverages, etc., can solve the problems of low taste, fragrance and active ingredients, low extraction rate of active ingredients of red ginseng, etc., and achieve the effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

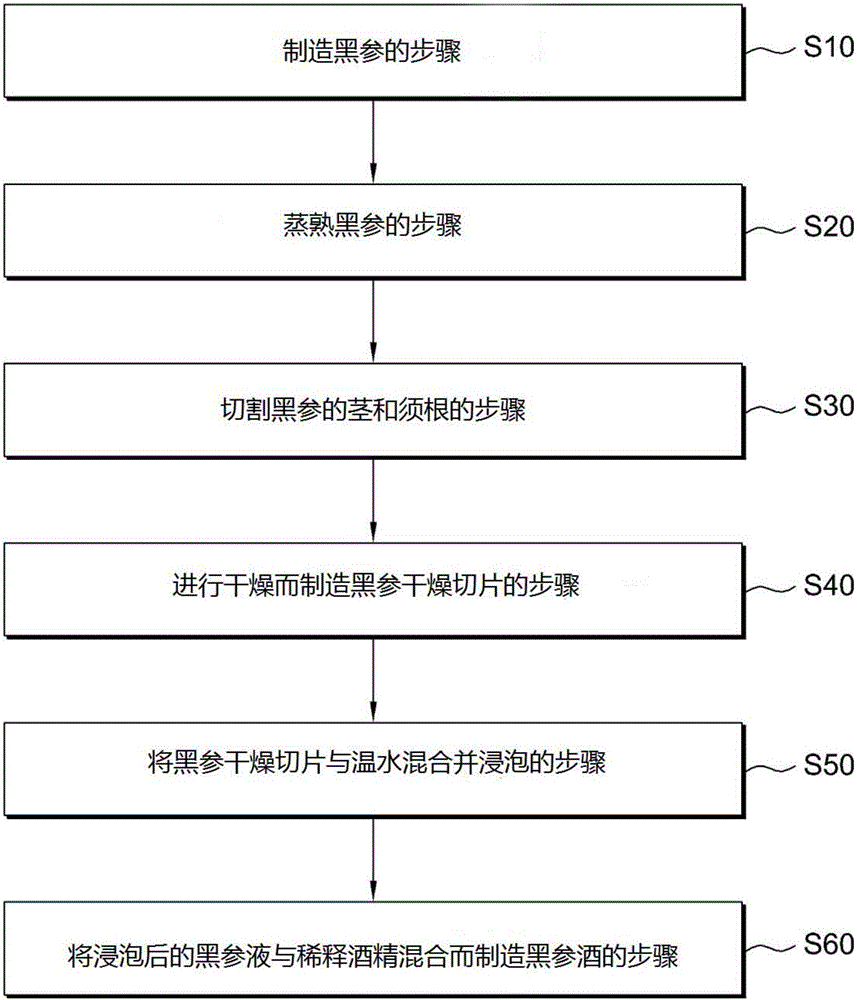

[0040] Production method of black ginseng wine using soaked black ginseng

[0041] After the fresh ginseng was steamed at 80°C for 2 hours, the process of drying at 50°C for 24 hours was repeated nine times to produce black ginseng.

[0042] The produced black ginseng was steamed at 70° C. for 50 minutes.

[0043] The stems of the steamed black ginseng were cut into a thickness of 5 mm, and the fibrous roots of the black ginseng were cut into a length of 2 cm.

[0044] The stem and fibrous roots of the cut black ginseng were dried to a moisture content of 17%, respectively, to manufacture dried slices of black ginseng.

[0045] 10 g of the dried black ginseng slices manufactured as described above were mixed with 200 ml of warm water at a temperature of 92° C. and soaked for 4 hours.

[0046] 200ml of the black ginseng liquid obtained through the soaking steps above was mixed with 800ml of diluted alcohol containing 20% ethanol to manufacture 1000ml of black ginseng wine. ...

experiment example 1

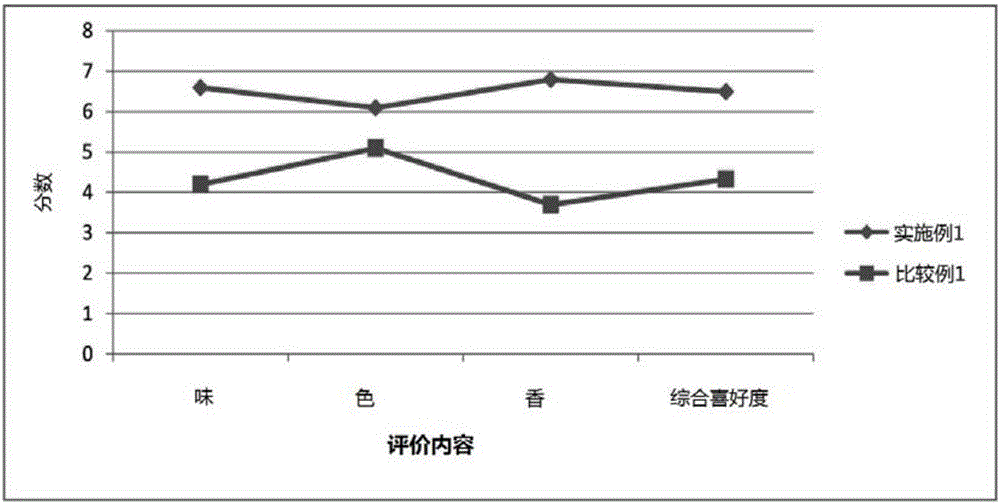

[0054] sensory evaluation

[0055] Select 20 healthy men and women aged 20-40 with normal alcohol metabolism, make each person drink about 100ml of black ginseng wine made in the embodiment 1 and comparative example 1, and evaluate the black ginseng wine by the 7-point method. The taste, color, fragrance and comprehensive preference of the wine are tested, and the results are shown in the following table 2 and figure 2 middle.

[0056] (Table 2) Sensory evaluation results

[0057] distinguish

taste

color

fragrant

Comprehensive preference

Example 1

6.6

6.1

6.8

6.5

Comparative example 1

4.2

5.1

3.7

4.3

[0058] Sensory evaluation standard: 7-point method

[0059] (1 point: very bad, 2 points: bad, 3: not good, 4: normal, 5 points: good, 6 points: good, 7 points: very good)

[0060] as described in Table 2 and figure 2 As shown in , the black ginseng wine made by soaking black ginseng produced by the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com