Integrated treatment method for reducing bioamine content in yellow wine

A treatment method, biogenic amine technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of incompleteness, poor practicability and reliability, and safety that needs further research, so as to prevent infection, overcome practicability and reliability performance, suitable for large-scale promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the preparation of zirconyl pyrophosphate packed column

[0020] Soak the zirconyl pyrophosphate powder in an aqueous solution with NaCl and NaOH concentrations of 0.01M at room temperature, stir it electromagnetically for 8 hours, and then filter and wash it with distilled water until the conductivity of the eluate is consistent with that of distilled water. Fill the final zirconyl pyrophosphate powder into the plexiglass column, let it stand for 2 to 3 hours, and then wash it with 20wt% ethanol solution for 1 hour at a flow rate of 220 to 400mL / h to form an aspect ratio of 16 to 20:1 Zirconyl pyrophosphate packed fixed bed.

Embodiment 2

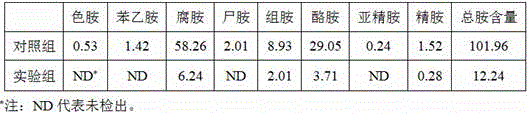

[0021] Example 2: A method for reducing biogenic amines in red yeast rice wine brewed by solid-state fermentation process

[0022] (1) According to the content of the patent "Production Technology of Refreshing Low-alcohol Yellow Rice Wine" (CN 101691533A), the solid-state fermentation method was used to produce red yeast rice wine, and the wine sample obtained after tubular membrane ultrafiltration was used as the control group.

[0023] (2) On the basis of the technological process of the control group, 5% of the total weight of commercially available pure propolis and 0.1‰ of ε-polylysine were added to the glutinous rice and japonica rice before fermentation in the vat; 5 days before the end of fermentation , add laccase in the amount of 25000U / kg to the fermented mash, add copper gluconate in the amount of 8mg / kg; finally the wine sample after tubular membrane ultrafiltration is prepared by Example 1 at a flow rate of 220-400mL / h Zirconyl pyrophosphate was used to fill the...

Embodiment 3

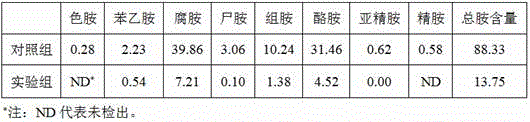

[0028] Example 3: A method for reducing biogenic amines in red yeast rice wine brewed by liquid fermentation process

[0029] (1) Referring to the contents of the literature "Development of a new process for brewing yellow rice wine by liquefaction method" (Sheng Fengyun. Jiangnan University, 2013: 5), the barley koji was replaced with red koji, and the red koji rice wine was brewed by liquid fermentation method. The obtained wine sample as a control group.

[0030] (2) On the basis of the process flow of the control group, 3% of its weight of natural propolis and its weight of 0.3‰ of ε-polylysine were added to the saccharified mash before alcoholic fermentation; Laccase was added to the mash in an amount of 10,000 U / kg; finally, the wine samples before canning were passed through the zirconyl pyrophosphate packed column prepared in Example 1 at a flow rate of 220-400 mL / h, and the obtained wine samples were used as the experimental group.

[0031] (3) According to the condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com