Yijun-sand-based matte porcelain glaze and preparation method thereof

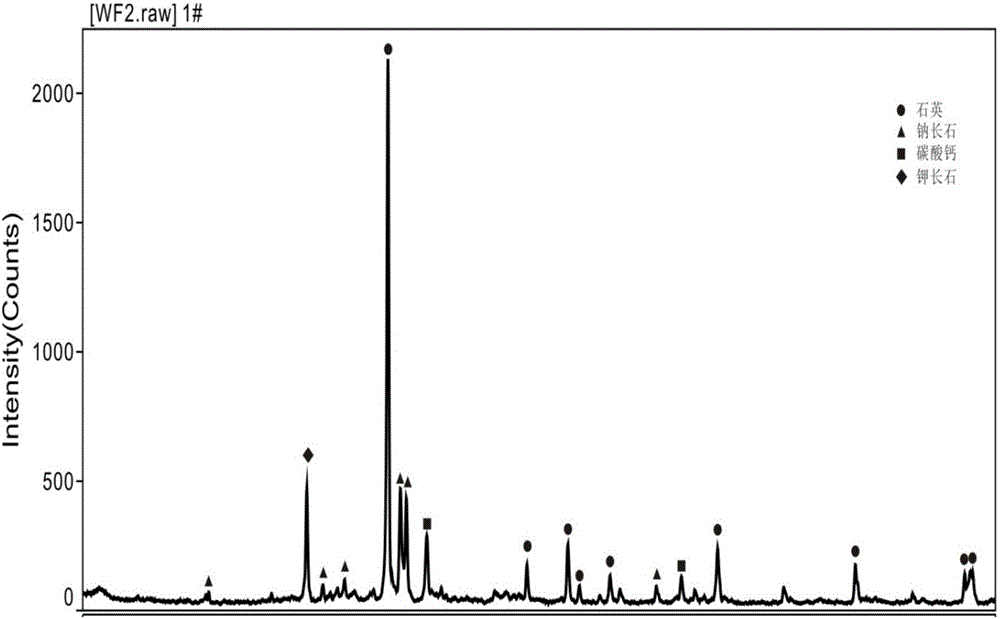

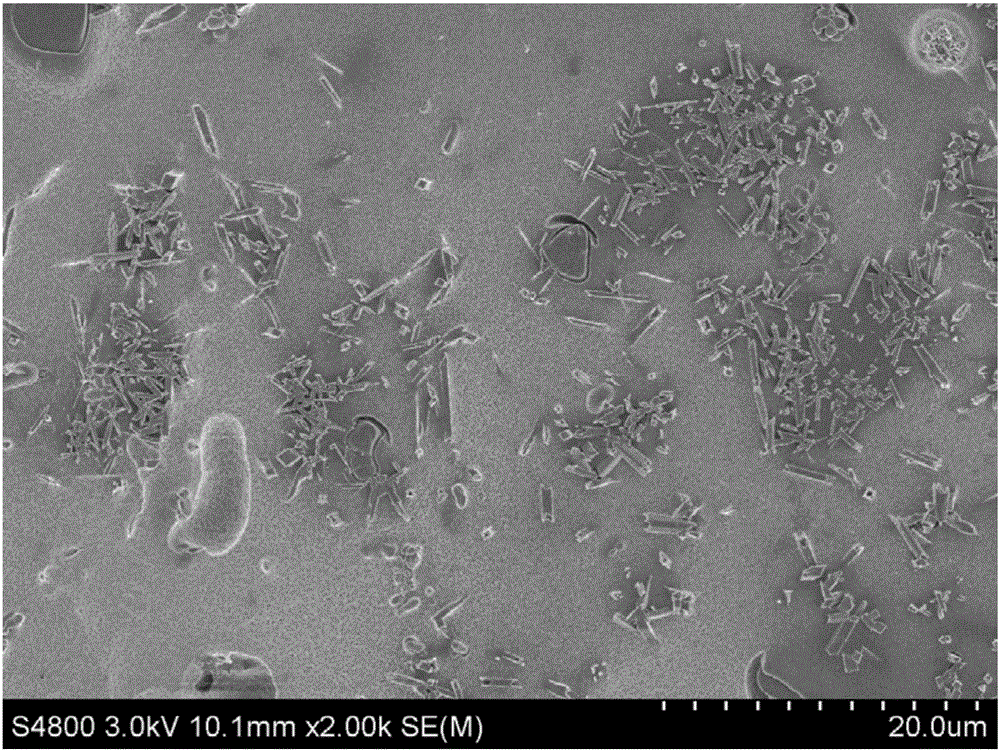

A technology of light porcelain and glaze slurry, which is applied in the field of matt enamel based on Yijun sand and its preparation, can solve the problems of high preparation price, unstable performance, poor hardness and wear resistance, etc., and achieve good wear resistance and glaze The effect of smooth and uniform surface and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

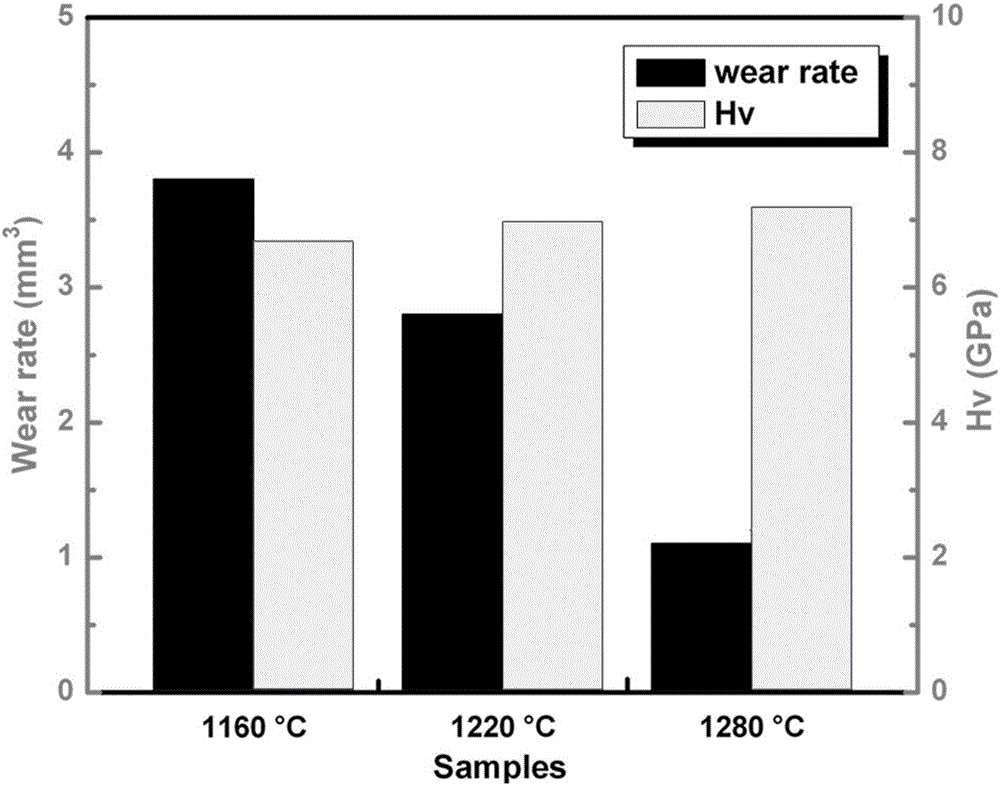

Embodiment 1

[0024] 1) Mix 80% Yijun sand and 20% raw loess uniformly by mass percentage to obtain a mixture, then add 0.4% sodium tripolyphosphate and 1% CMC to the mixture, mix uniformly, and finely grind to 250 mesh , the specific gravity of the prepared glaze slurry is 1.7g / cm 3 ;

[0025] 2) Apply the glaze slurry evenly on the body, raise the temperature to 1210°C, keep it warm for 35 minutes and cool naturally to obtain a high-hardness matte enamel with a Vickers hardness of 7.0GPa.

Embodiment 2

[0027] 1) Mix 70% Yijun sand and 30% raw loess uniformly according to mass percentage to obtain a mixture, then add 0.3% sodium tripolyphosphate and 1% CMC to the mixture, mix uniformly, and finely grind to 250 mesh , the specific gravity of the prepared glaze slurry is 1.7g / cm 3 ;

[0028] 2) Apply the glaze slurry evenly on the body, raise the temperature to 1230°C, keep it warm for 20 minutes and cool naturally to obtain a high-hardness matt enamel with a Vickers hardness of 7.1GPa.

Embodiment 3

[0030] 1) Preparation of cooked loess: Grind the raw loess evenly in a mortar, place it in a high-temperature furnace for calcination at 600°C and keep it warm for 30 minutes. After cooling, use a 900r / h ball mill to pass through an 80-mesh sieve for 30 minutes. Deri loess;

[0031] 2) Mix 50% Yijun sand, 25% raw loess, and 25% cooked loess to obtain a mixture by mass percentage, then add 0.4% sodium tripolyphosphate and 2% CMC to the mixture and mix evenly , finely ground to 250 mesh, and the specific gravity of the prepared glaze slurry is 1.6g / cm 3 ;

[0032] 3) Apply the glaze slurry evenly on the green body, raise the temperature to 1220°C, keep it warm for 40 minutes and cool naturally to obtain a high-hardness matt enamel with a Vickers hardness of 7.0GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com