Method for preparing graphene / carbon nanotube composite material

A technology of composite materials and carbon nanotubes, applied in the direction of carbon nanotubes, multi-walled carbon nanotubes, nanocarbons, etc., can solve the problems of complex preparation process, harsh experimental conditions, high experimental cost, etc., achieve simple process, improve composite uniformity Sexuality and parameter controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

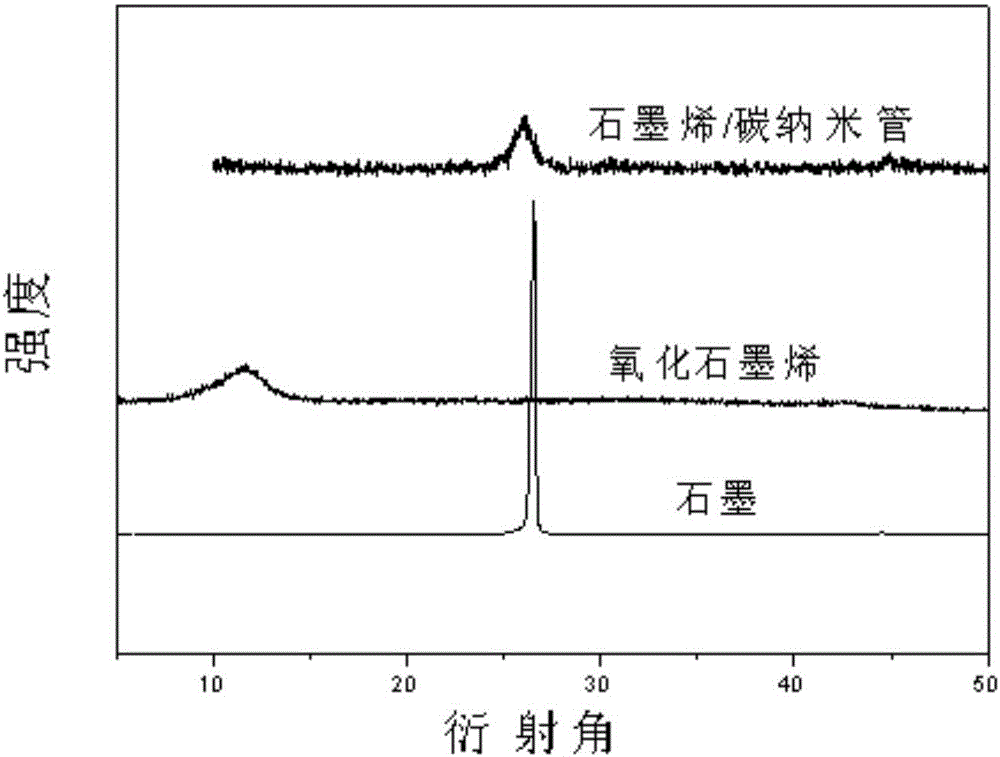

[0032] Add 3g of graphite powder and 2g of sodium nitrate into the beaker, slowly add 70mL of concentrated sulfuric acid along the beaker and keep stirring; under the condition of ice bath, add 30g of potassium permanganate solid powder into the beaker in five times and keep stirring 1h. Stirring was continued for 2 h in a water bath at 35 °C to obtain a mixed solution. Slowly add 140mL deionized water into the solution and keep stirring for 15min, then the temperature of the system rises to about 95°C, and continue stirring for 3h; dropwise add 30% H 2 o 2 until the solution turned bright yellow. The reaction solution was filtered while hot, and washed with dilute hydrochloric acid to remove excess metal ions. Graphene oxide was prepared by centrifuging and washing to pH 7, freeze-drying for 48 hours, vacuum degree 8-pa, temperature: -10°C, and its crystal plane structure was confirmed by X-ray diffractometer, refer to the attached figure 1 . The XRD results show that th...

Embodiment 2

[0037] The preparation method of the graphene / carbon nanotube composite material, the operation steps are as follows: (1) graphene oxide is prepared by oxidation reaction of natural graphite powder; Hydrothermal reaction to prepare graphene / carbon nanotube composites.

[0038] Step (1) The operating steps are the same as in Example 1.

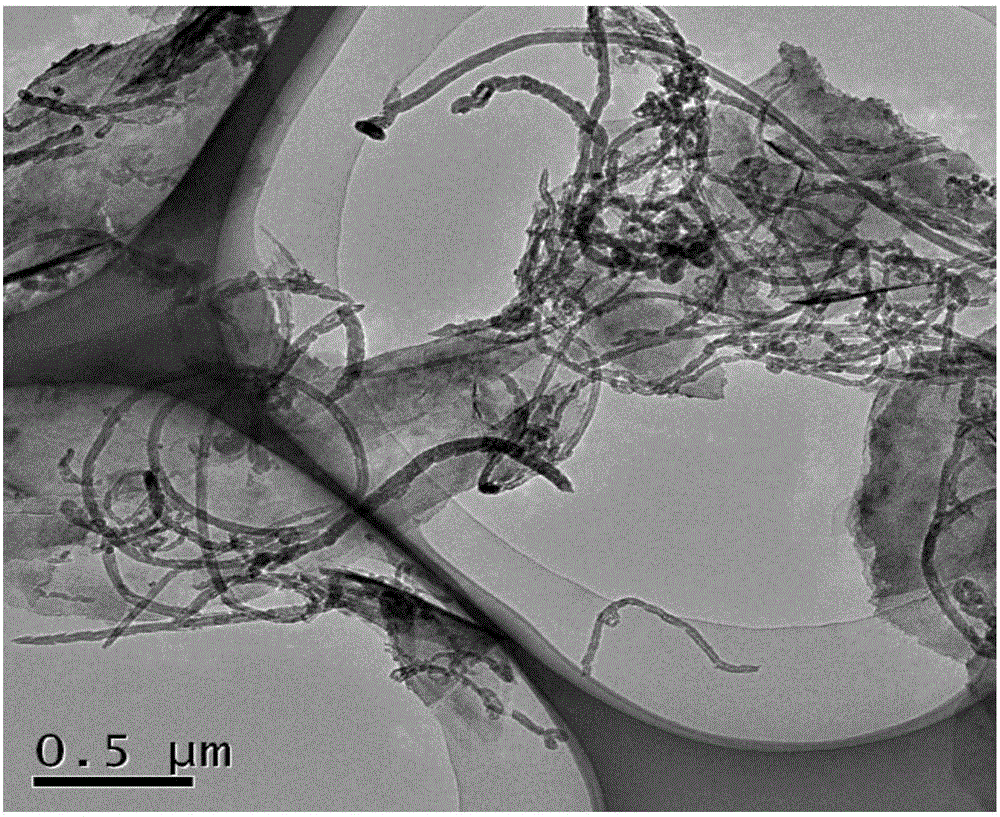

[0039] Step (2) The operation steps are as follows: Add graphene oxide and deionized water into a beaker for ultrasonic dispersion for 1 h, then add Ni(NO3)2·6H2O and hexamethylenetetramine (HMTA) and stir well; the solution is transferred to React at a constant temperature in a 100mL reactor; after the reaction, add excess hydrochloric acid with a concentration of 1mol / L to dissolve nickel hydroxide, take a black solid after suction filtration, wash and dry in vacuum to obtain a graphene / carbon nanotube composite material.

[0040] The freeze-drying time is 30-50 hours, the temperature is -18°C, and the vacuum degree is 9 Pa.

[0041] In the s...

Embodiment 3

[0048] The preparation method of graphene / carbon nanotube composite material is characterized in that operation steps are as follows: (1) natural graphite powder prepares graphene oxide through oxidation reaction; (2) graphene oxide and nickel nitrate hexahydrate, hexamethylenetetrafluoroethylene Amines undergo ultrasonic hydrothermal reaction to prepare graphene / carbon nanotube composites.

[0049] Step (1) The operating steps are the same as in Example 1. The different process parameters are: the freeze-drying time is 50 hours, the temperature is -40° C., and the vacuum degree is 10 Pa.

[0050] The operation steps of the step (2) are as follows: take graphene oxide and deionized water and add them to a beaker for ultrasonic dispersion for 1.5h, then add Ni(NO3)2·6H2O and hexamethylenetetramine (HMTA) and stir well; The solution was transferred to a 100mL reactor for constant temperature reaction; after the reaction was completed, an excess concentration of 1mol / L hydrochlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer spacing | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com