Pinion-and-rack type elevator under balanced drive

A driving gear and rack type technology, applied in the field of elevators, can solve problems such as unbalanced force on the elevator car, self-heavy elevator car, and complex transmission system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

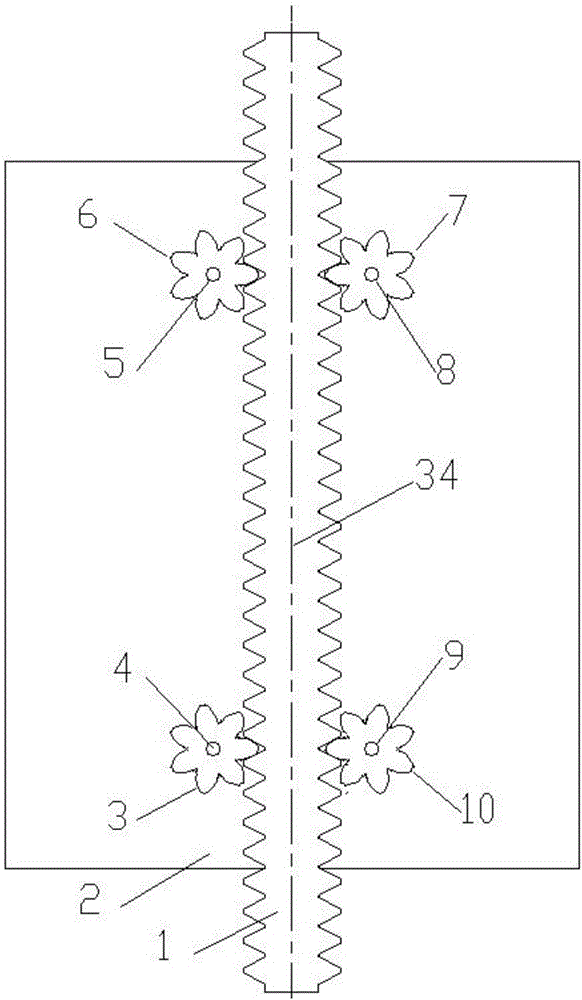

[0018] Embodiment 1, with Figure 1~4 It is also the accompanying drawing of embodiment 1, and the description of the composition and function of each part of its structure is shown in [0005] and [0006]. Since it involves the coordination of multiple transmission systems, special attention should be paid to manufacturing The quality and installation quality must ensure the necessary accuracy, and the trial operation can only be carried out after passing the test. The test includes ultrasonic flaw detection of the driving gear and rack materials, and the verticality of the guide rail is measured by a laser elevator guide rail verticality measuring instrument; Its electrical control system uses an embedded system as the main control system, and the "power-off star connection" unit circuit and the attached Figure 5 And [0007] the same as described in the paragraph; its work process is mainly, when the system has no electricity, including disconnecting the power switch or unexpec...

Embodiment 2

[0019] Embodiment 2, with Figure 1~2 Also applicable to Embodiment 2, the description of the composition and function of each part of its structure is described in [0005] and [0006]. Since it involves the coordination of multiple transmission systems, special attention should be paid to the quality of manufacture and The installation quality must ensure the necessary accuracy, and the test run can only be carried out after passing the test. The test includes ultrasonic flaw detection of the driving gear and rack materials, and the verticality of the guide rail is measured by a laser elevator guide rail verticality measuring instrument; its electrical The control system uses an embedded system as the main control system, and the "power-off star connection" unit circuit and the attached Figure 5 And [0007] paragraph described same, its work process is also roughly the same with embodiment 1; Its transmission system has been changed in the scope of the basic ideas of the claims...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com