Automatic deviation correcting mechanism needed for automobile part production

A technology for auto parts and automatic deviation correction, which is applied in the direction of thin material handling, transportation and packaging, winding strips, etc., and can solve problems such as overlapping, offset, and uneven laying

Inactive Publication Date: 2016-12-21

湖北吉兴汽车部件有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to meet the conditions of the above-mentioned ceiling, on the automatic production line of the wet-process ceiling, the raw materials of the wet-process ceiling are divided into 6 layers, which are divided into 3 handling processes and then assembled. The three-layer material often shifts and overlaps under the operation of the existing mechanism, resulting in irregular laying of the six-layer material after combination, requiring manual adjustment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0033] Example 1: Dongfeng Honda 2CE roof, the roof specification is L1830×W1340mm, this equipment is designed by Jixing itself, the main frame structure is manufactured by Jixing, and the rest of the raw materials are purchased from the market, and Jixing assembles it by itself.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

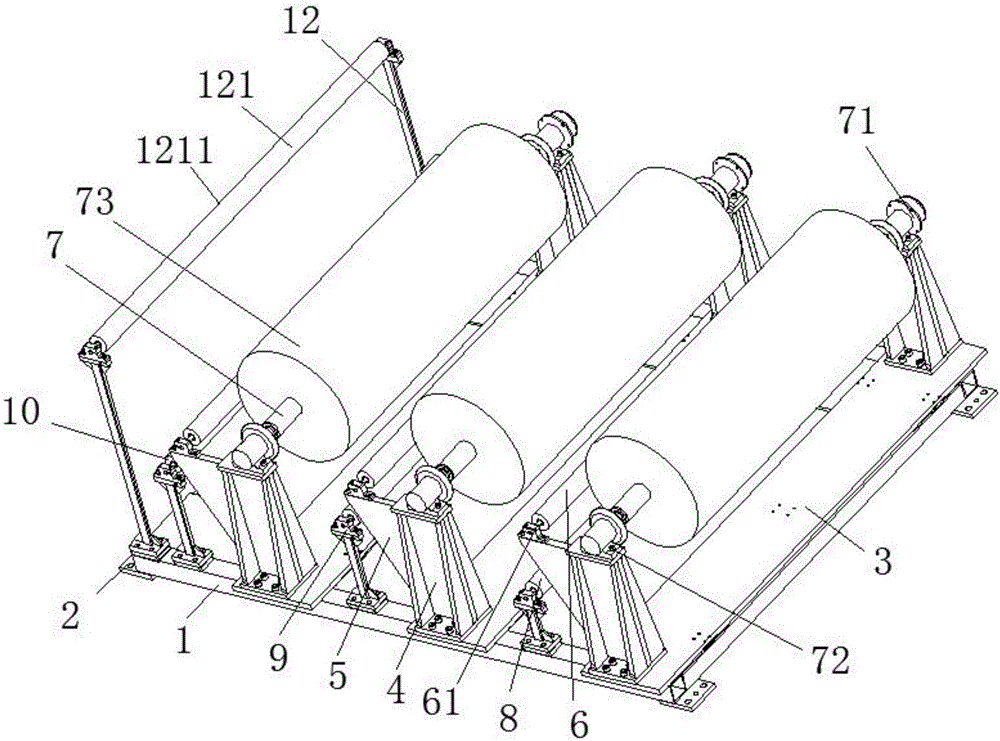

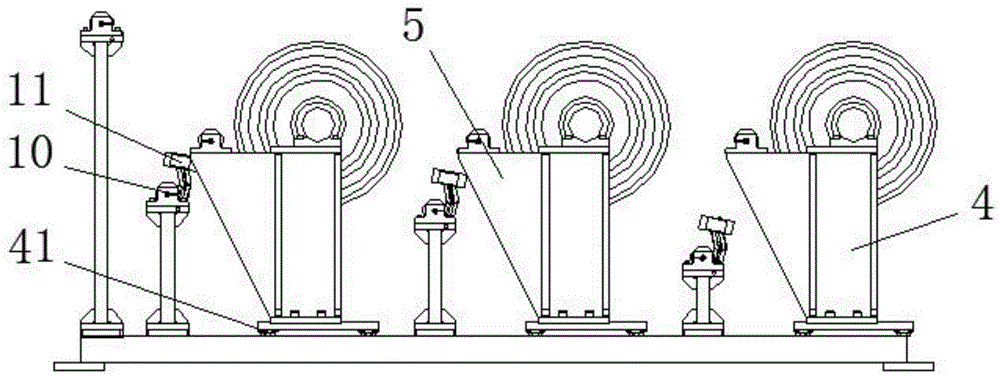

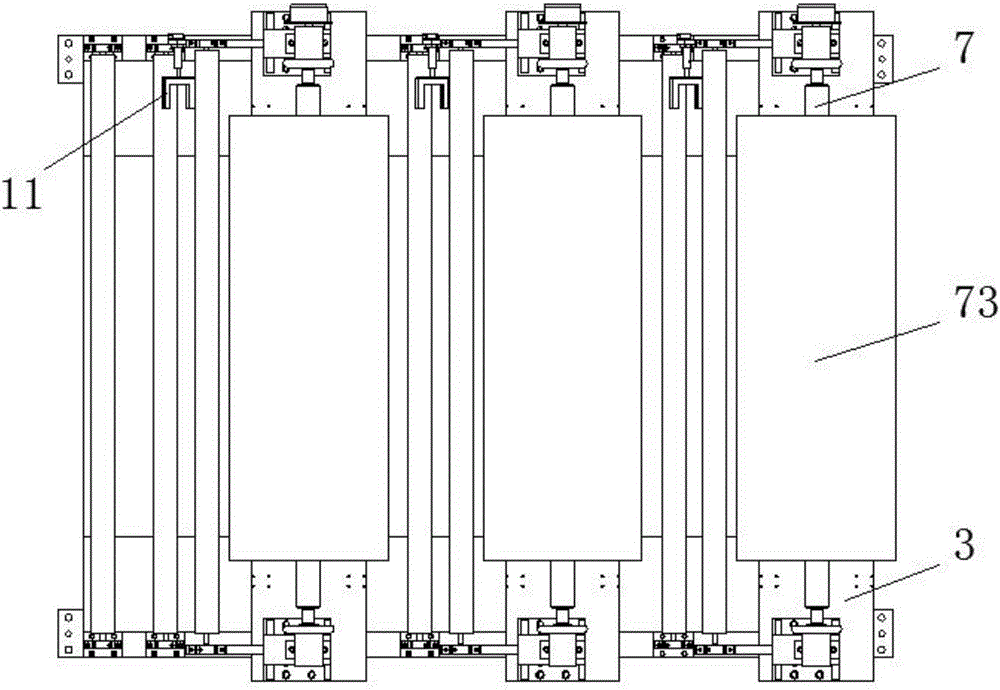

The invention discloses an automatic deviation correcting mechanism needed for automobile part production. The automatic deviation correcting mechanism comprises a base body. The top of the base body is connected with three transverse plates at equal intervals, and the three transverse plates are arranged side by side. The upper portions of supporting plates fixedly connected to the tops of the transverse plates are movably connected with material fixing shafts. The top of the base body is connected with a left parallel guiding shaft, a middle parallel guiding shaft and a right parallel guiding shaft from left to right at equal intervals. Y type infrared position sensors are arranged on the same side of the left parallel guiding shaft, the middle parallel guiding shaft and the right parallel guiding shaft. According to the automatic deviation correcting mechanism, three layers of materials can be combined and subjected to pull cutting, the three layers of materials can be kept in a tensioned state and an alignment state all the time in the pull cutting process, the position consistency of the multiple layers of materials after the materials are combined in the production process is guaranteed, the reject ratio and the equipment abnormality occurring probability in the product manufacturing process are reduced, and the quality abnormal action except the standard operation procedures of workers is reduced.

Description

technical field [0001] The invention relates to the technical field of production equipment required for the production of automobile wet-process roof products, in particular to the technical field of an automatic feeding deviation correction mechanism, in particular to an automatic deviation correction mechanism required for the production of auto parts. Background technique [0002] The car roof is generally installed on the top of the car to play the role of heat insulation, sound insulation and beautification. In the era of more and more pursuit of high performance, environmental protection, energy saving, lightweight, and individualization, the interior of a car, like the shape of a car, has become an important factor for people to choose a car. Therefore, the requirements for automotive interior parts are getting higher and higher. [0003] In order to meet the conditions of the above-mentioned ceiling, on the automatic production line of the wet-process ceiling, the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65H23/26

CPCB65H23/038B65H2553/41B65H2511/24

Inventor 钱怡敏

Owner 湖北吉兴汽车部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com