Launching and recycling system and corresponding method of shipborne underwater glider

An underwater glider and recovery system technology, applied in underwater ships, underwater operation equipment, motor vehicles, etc., can solve problems such as personal injury, large impact of wind and waves, and large impact of wind and waves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below through specific embodiments.

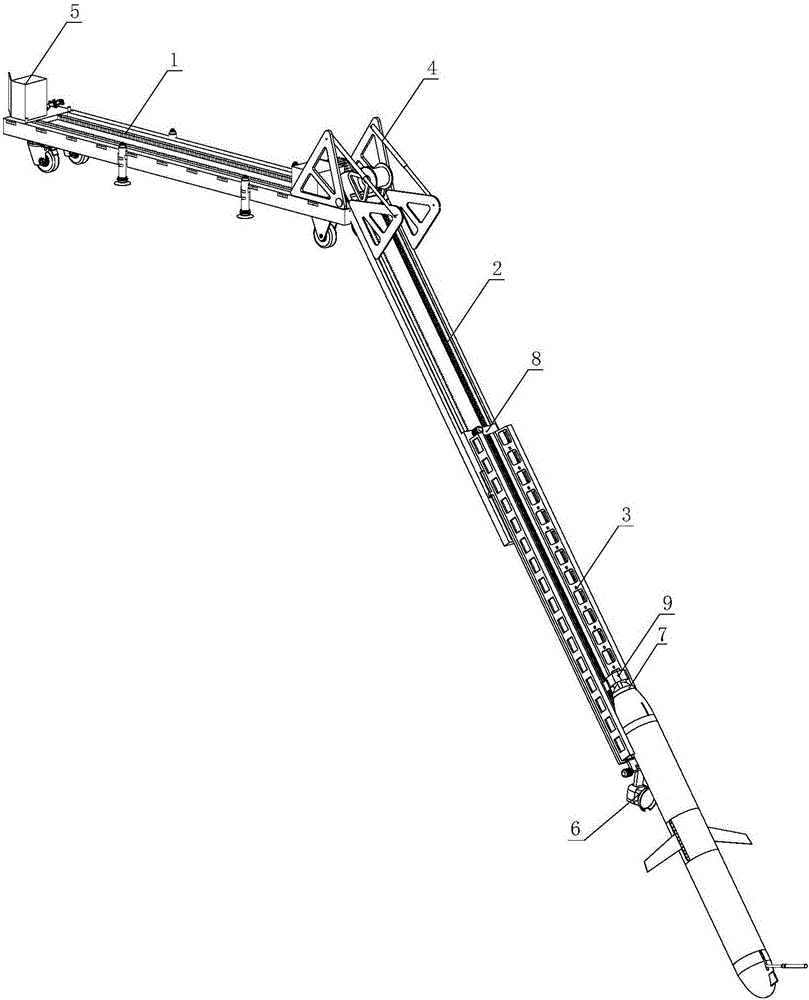

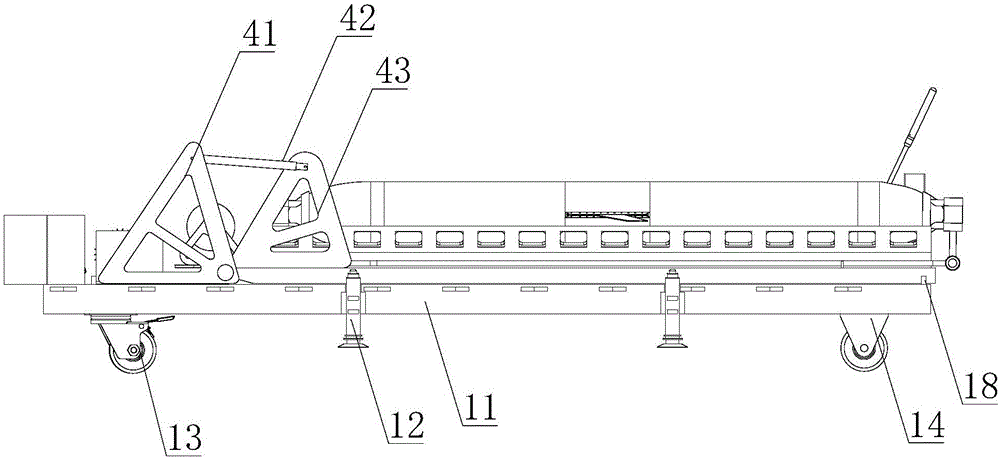

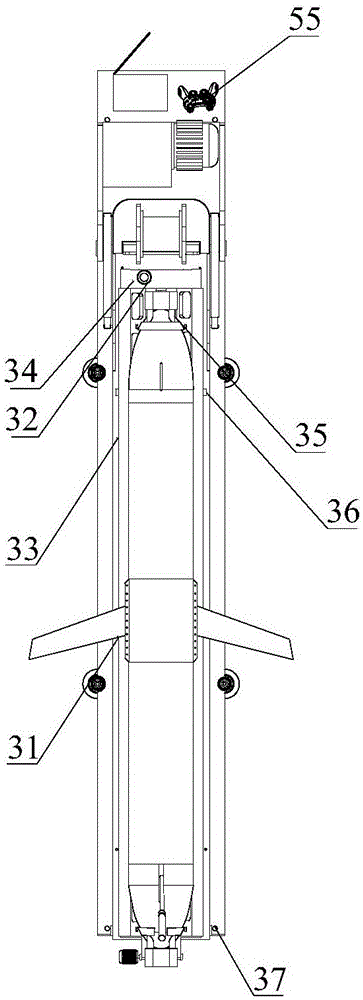

[0054] like Figure 1-13 As shown, a ship-based underwater glider deployment and recovery system includes: a ship-based main body 1, a main recovery slideway 2, an auxiliary recovery slideway 3, an electric turning mechanism 4, an electric control box 5, a tightening mechanism 6, multiple Sensor fusion positioning system 7, dragging unit 8, the hook system 9, the ship base body 1 includes: ship base body 11, telescopic outrigger 12, guide wheel 13, guide wheel bracket 14, ship base main body track 15 , ship base main body rack 16, turning shaft 17, ship base body limit switch 18. Wherein there are totally four telescopic legs 12, which are installed at the positions of the left and right sides of the basic body 11 of the ship to improve the stability of the basic body 11 of the ship when working. It should be noted that when the system is deployed and recovered, the four telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com