Copper phosphorus tin flux-cored wire and preparation method thereof

A technology of flux-cored welding wire and copper-phosphorus, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of high-phosphorus copper-phosphorus-tin welding wire difficult to process, low brazing seam strength, poor flow spreading, etc., to achieve enhanced self-brazing High performance, easy operation and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

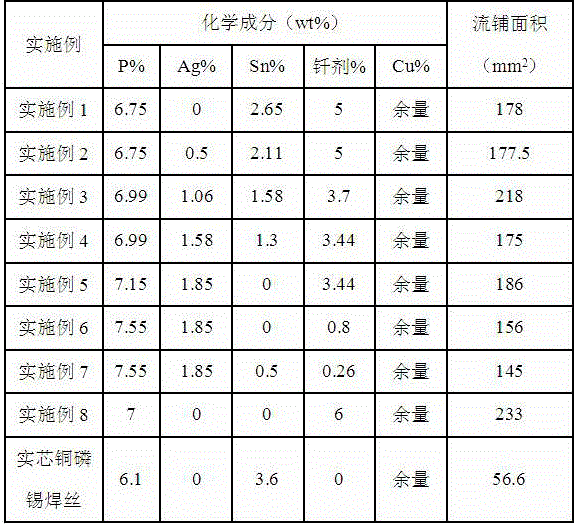

Embodiment 1

[0042] A copper-phosphorus-tin flux-cored welding wire. The flux-cored welding wire is formed by rolling and drawing a copper tube with a wall thickness of 2mm and an inner diameter of Φ16mm to cover a flux core, wherein the flux core is calculated according to the mass percentage Composed of the following ingredients: 85% Cu-15P master alloy powder, 0% Ag powder, 5% Sn powder, 10% flux powder, the compaction density of each component in the drug core is between 5.5-5.6, the filling of the drug core The rate is 53%, and the flux powder is composed of K 2 B 4 o 7 ·5H 2 O, H 3 BO 3 and NaF according to the mass ratio of 2:2:1 composition.

[0043] A method for preparing copper-phosphorus-tin flux-cored wire, comprising the following steps:

[0044] Step 1, select a certain length of copper tube with a wall thickness of 2 mm and an inner diameter of Φ16 mm and calculate the quality of the section of copper tube, and then according to the filling rate of the drug core descri...

Embodiment 2

[0051] A copper-phosphorus-tin flux-cored welding wire. The flux-cored welding wire is formed by rolling and drawing a copper tube with a wall thickness of 2mm and an inner diameter of Φ16mm to cover a flux core, wherein the flux core is calculated according to the mass percentage Composed of the following ingredients: 85% Cu-15P master alloy powder, 1% Ag powder, 4% Sn powder, 10% flux powder, the compaction density of each component in the drug core is between 5.5-5.6, the filling of the drug core The rate is 53%, and the flux powder is composed of K 2 B 4 o 7 ·5H 2 O, H 3 BO 3 and NaF according to the mass ratio of 2:2:1 composition.

[0052] The preparation method of embodiment 2 is the same as embodiment 1.

Embodiment 3

[0054] A copper-phosphorus-tin flux-cored welding wire. The flux-cored welding wire is formed by rolling and drawing a copper tube with a wall thickness of 2mm and an inner diameter of Φ16mm to cover a flux core, wherein the flux core is calculated according to the mass percentage It is composed of the following ingredients: 88% Cu-15P master alloy powder, 2% Ag powder, 3% Sn powder, 7% flux powder, the compaction density of each component in the drug core is between 5.5-5.6, the filling of the drug core The rate is 53%, and the flux powder is composed of K 2 B 4 o 7 ·5H 2 O, H 3 BO 3 and NaF according to the mass ratio of 2:2:1 composition.

[0055] The preparation method of embodiment 3 is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com