A fast processing device for waste mosaic tiles

A processing device and mosaic technology, applied in the direction of grain processing, solid waste removal, cleaning methods and utensils, etc., can solve the problems of short processing time and long processing time, and achieve time saving, cleaning time saving, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

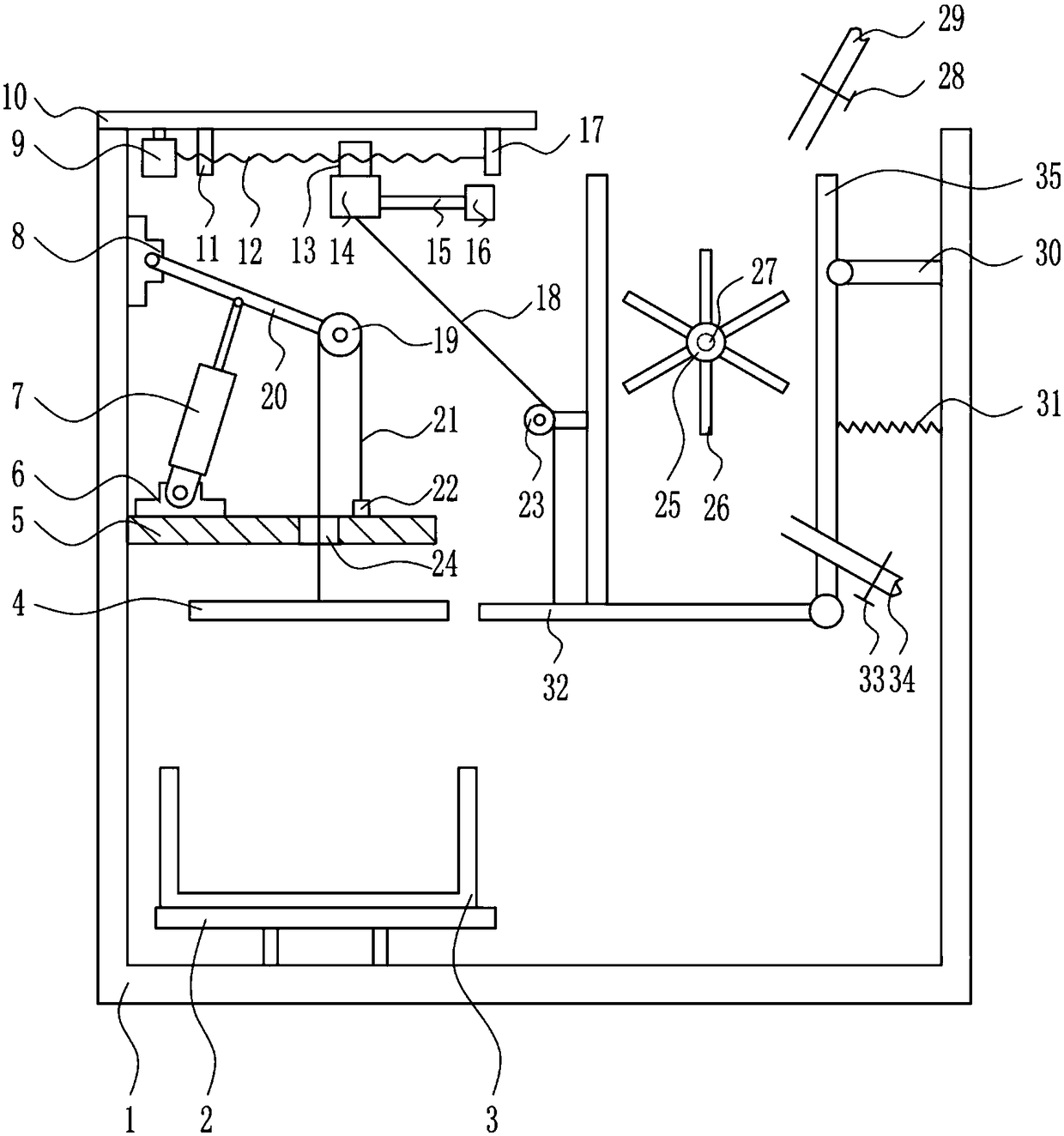

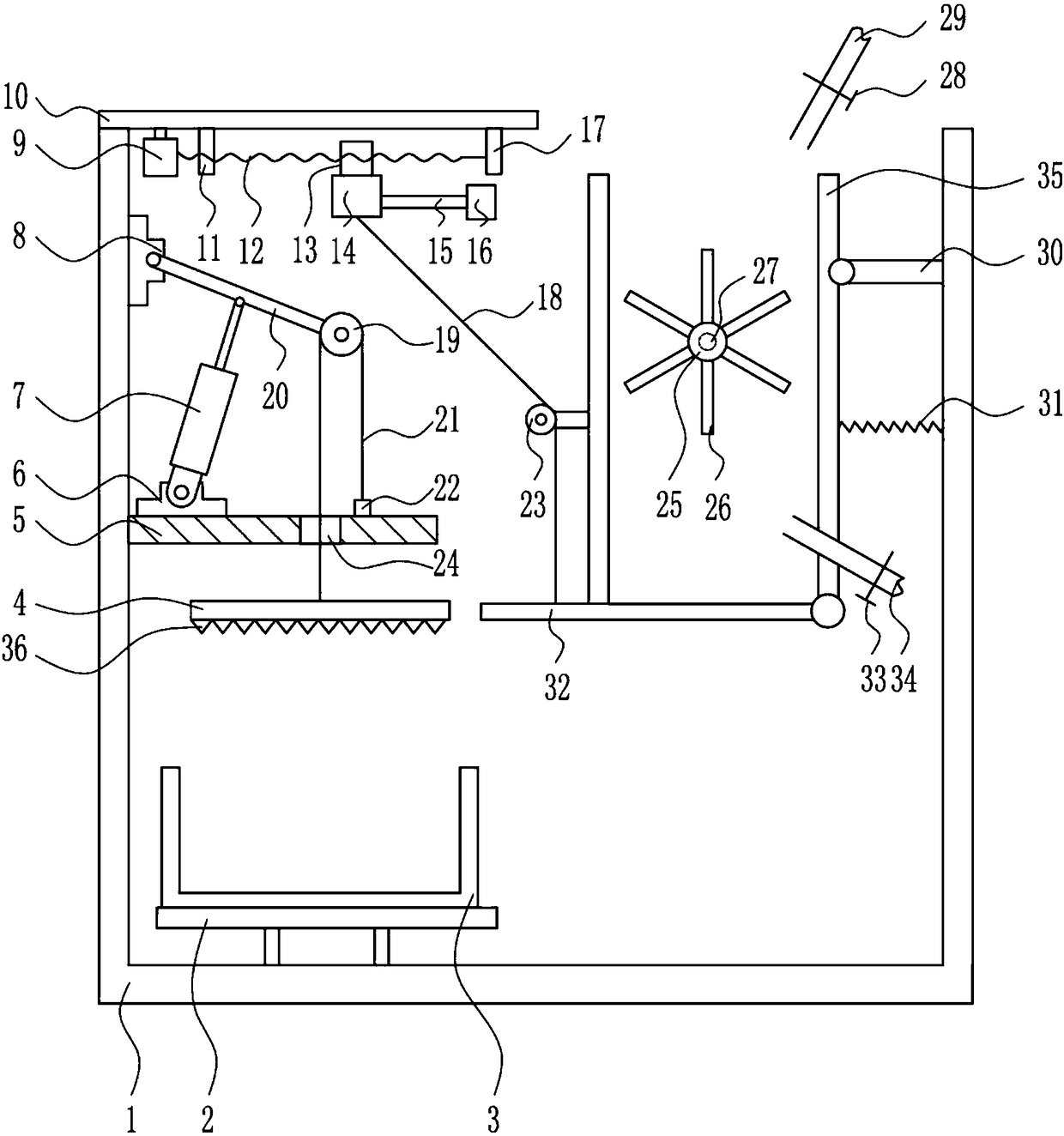

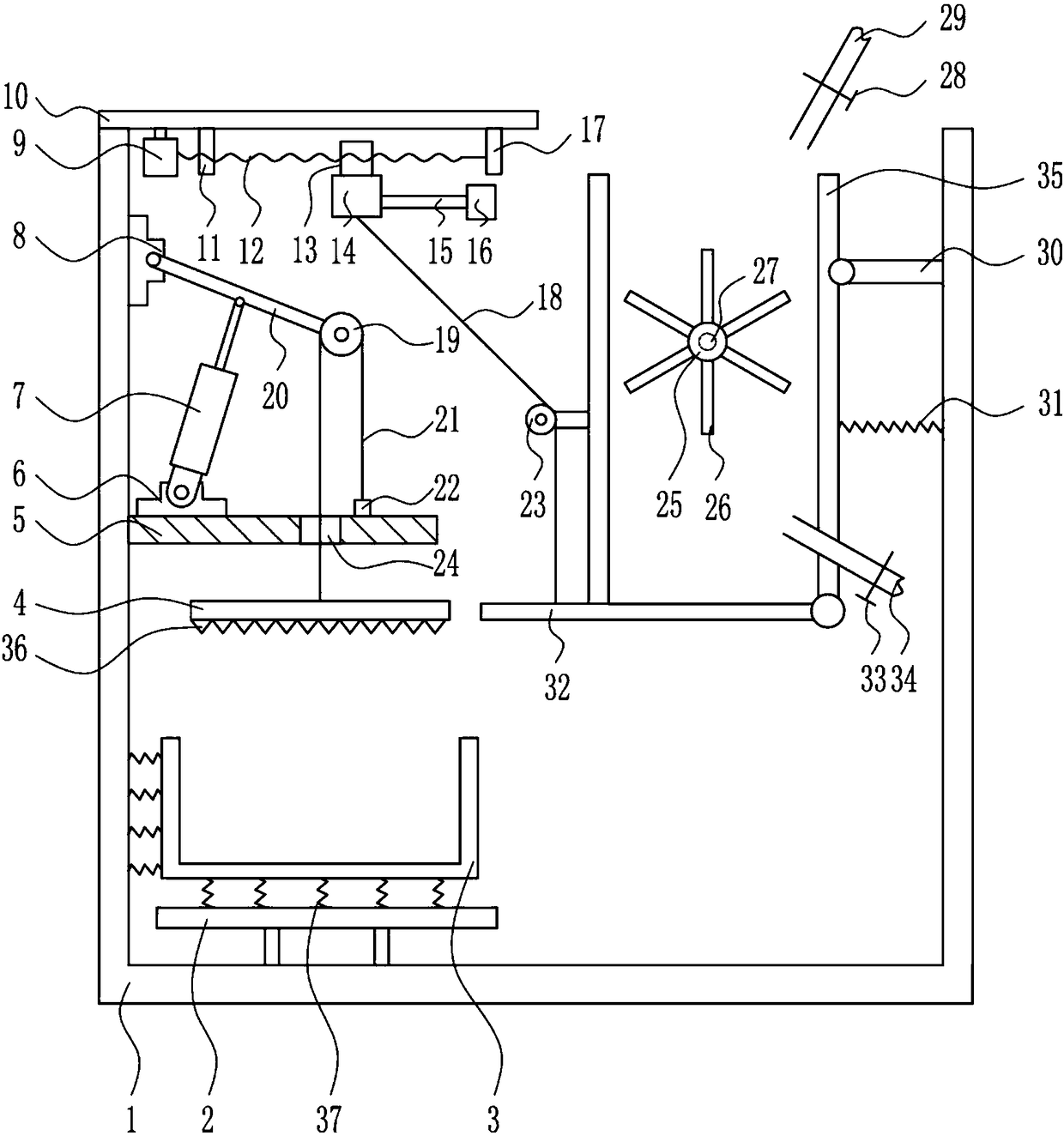

[0041] A kind of waste and old mosaic tile fast processing device, such as Figure 1-9 As shown, it includes a fixed frame 1, a placing table 2, a rolling groove 3, a pressing block 4, a guide plate 5, a first swing seat 6, a cylinder 7, a second swing seat 8, a first motor 9, a top plate 10, a left Bearing seat 11, screw rod 12, nut 13, fixed block 14, push rod 15, push block 16, right bearing seat 17, pull wire 18, first pulley 19, swing rod 20, pull rope 21, fixed ring 22, fixed pulley 23. Disc 25, stirring plate 26, second motor 27, first valve 28, water inlet pipe 29, fixed rod 30, first elastic element 31, iron baffle plate 32, second valve 33, water outlet pipe 34 and cleaning Box 35; the bottom of the fixed frame 1 is provided with a placing platform 2, the top of the placing platform 2 is provided with a rolling groove 3, and the left side of the fixed frame 1 is provided with a second swing seat 8 and a guide plate 5, and the guide plate 5 is located at the second sw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com