Outsole, method for attaching outsole to mid-sole and made shoe sole

A lamination and outsole technology, applied in the direction of shoe soles, footwear, footwear, etc., can solve the problems of re-drying and lamination, degumming of lamination parts, and insufficient lamination tension, etc., to reduce mold and time costs , to ensure aesthetics and durability, and to improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

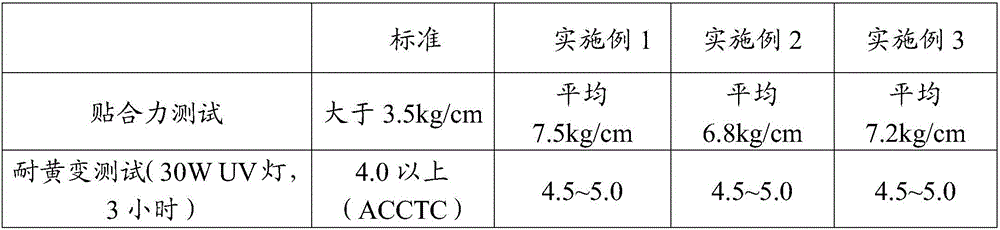

Embodiment 1

[0027] An embodiment of the outsole of the present invention, the outsole in this embodiment comprises an outsole base layer, a rubber stock solution film layer compounded on the outsole base layer, and a release mold compounded on the rubber stock solution film layer Film layer, the thickness of the rubber stock solution film layer is 0.08mm, the material of the rubber stock solution film is F1-1500 produced by hen kel company, and the release film is a layer of paper film protective film on the surface of the rubber stock solution film.

[0028] The preparation method of the outsole described in this embodiment is as follows: inject the base material of the outsole in the outsole mould, then put in the raw rubber liquid film (there is a layer of release film on the surface of the raw rubber liquid film), and after injection molding, obtain the outsole end.

[0029] A method for bonding the large bottom and the midsole described in the present embodiment comprises the followi...

Embodiment 2

[0037] An embodiment of the outsole of the present invention, the outsole in this embodiment comprises an outsole base layer, a rubber stock solution film layer compounded on the outsole base layer, and a release mold compounded on the rubber stock solution film layer Film layer, the thickness of the rubber stock solution film layer is 0.05mm, the material of the rubber stock solution film is F1-1500 produced by hen kel company, and the release film is a layer of film protection film on the surface of the rubber stock solution film.

[0038] The preparation method of the outsole described in this embodiment is as follows: inject the base material of the outsole in the outsole mould, then put in the raw rubber liquid film (there is a layer of release film on the surface of the raw rubber liquid film), and after injection molding, obtain the outsole end.

[0039] A method for bonding the large bottom and the midsole described in the present embodiment comprises the following ste...

Embodiment 3

[0047] An embodiment of the outsole of the present invention, the outsole in this embodiment comprises an outsole base layer, a rubber stock solution film layer compounded on the outsole base layer, and a release mold compounded on the rubber stock solution film layer Film layer, the thickness of the rubber stock solution film layer is 0.065mm, the material of the rubber stock solution film is F1-1500 produced by hen kel company, and the release film is a layer of film protection film on the surface of the rubber stock solution film.

[0048] The preparation method of the outsole described in this embodiment is as follows: inject the base material of the outsole in the outsole mould, then put in the raw rubber liquid film (there is a layer of release film on the surface of the raw rubber liquid film), and after injection molding, obtain the outsole end.

[0049] A method for bonding the large bottom and the midsole described in the present embodiment comprises the following st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com