Method for producing hot-rolled seamless pipes from transformable steel, in particular for pipelines for deep-water applications, and corresponding pipes

A seamless tube, deep water technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems such as increasing corrosion sensitivity, forming cracks, increasing hardness, etc., to achieve excellent mechanical properties and corrosion resistance, cold crack formation The effect of reducing the tendency of the excellent solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

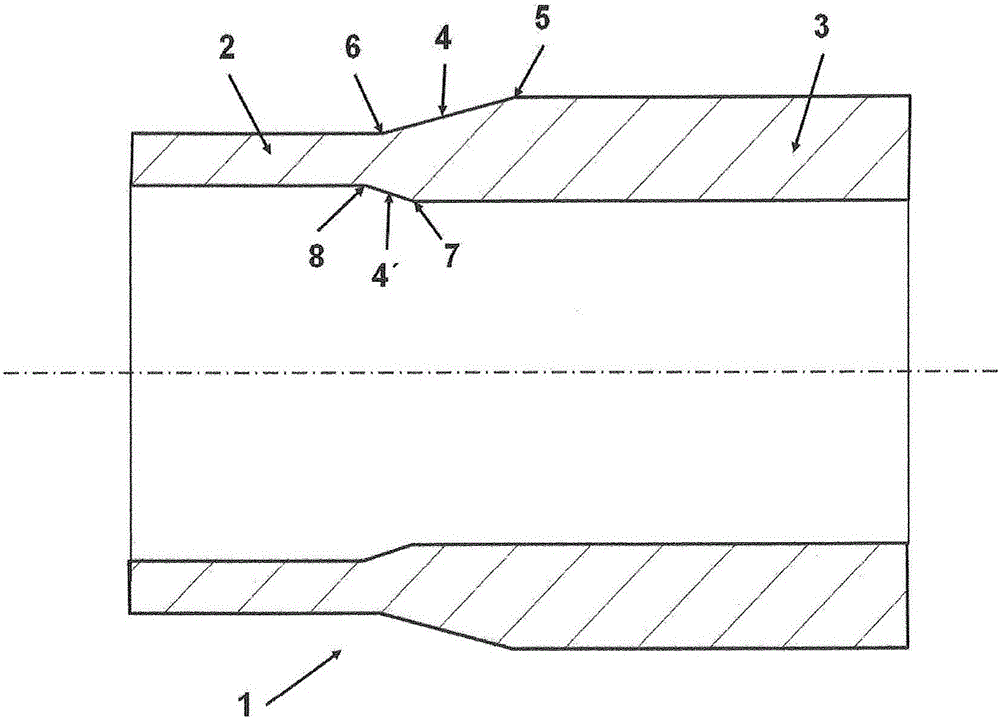

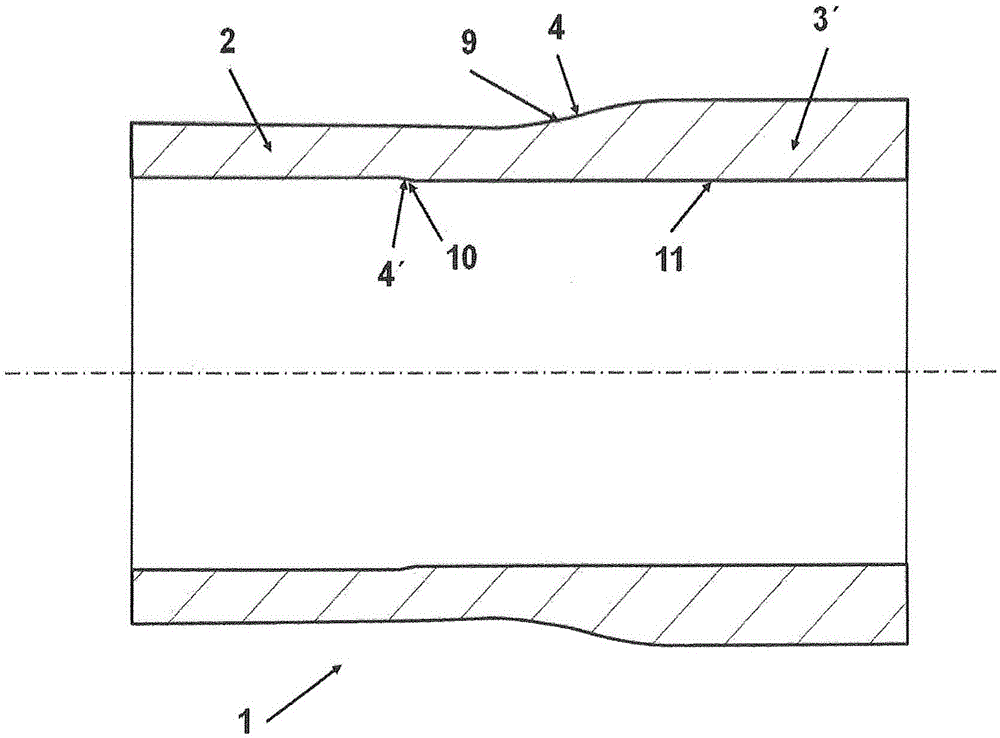

[0145] figure 1 Shown is a part of a pipe 1 produced according to the invention in a longitudinal section from the transition region between the pipe body 2 and the pipe ends 3, said pipe 1 having at least one but preferably both pipe ends 3 with a to The thickened wall portion on the outside and inside of the tube.

[0146] At the tube end 3 the tube 1 has a thickened wall which is produced by upsetting in a hot working step and which changes into the outlet cross-section of the tube body 2 of the tube 1 through the transition zone 4,4' .

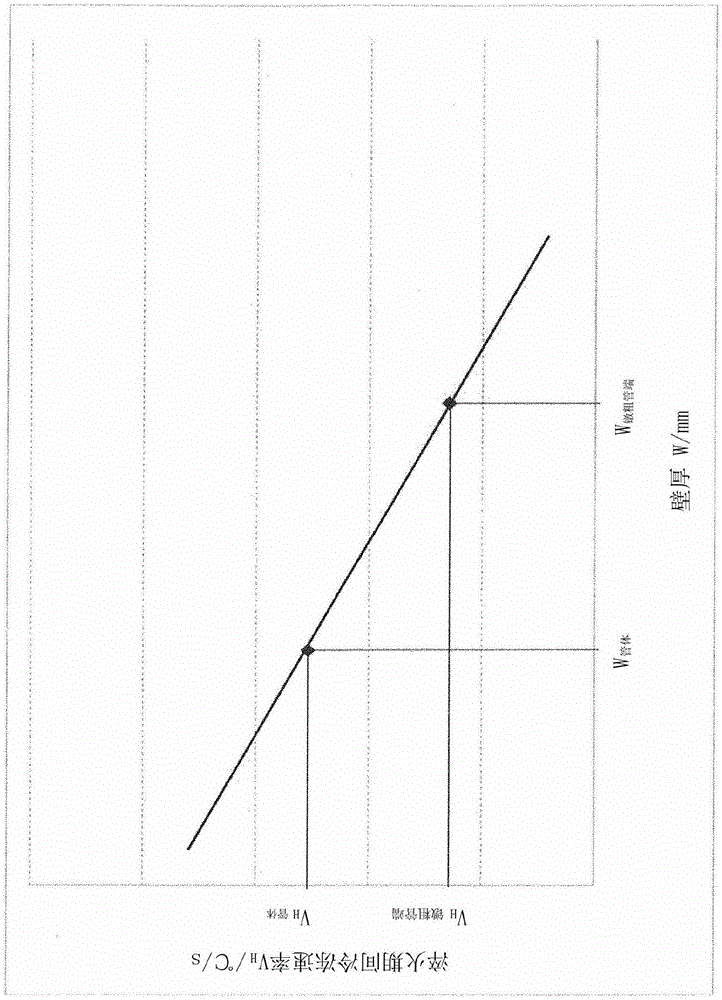

[0147] In this example, the thickened wall portion 3 is made such that the outer diameter of the tube 1 is increased and the inner diameter is reduced. Based on the outlet cross-section of the tube 1 and thus the cross-section of the non-upset tube body 2, the wall thickness of the tube end 3 is three times the thickened wall of the outlet tube. Therefore, in this case, the wall thickness ratio of the upset pipe end 3 and the intermedia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com