Method and system for analyzing longitudinal interaction of longitudinal connecting plate type ballastless track and bridge

A slab-type ballastless track, ballastless track technology, applied in special data processing applications, instruments, electrical digital data processing and other directions, can solve the longitudinal interaction without considering the interaction between steel and concrete, ballastless track concrete cracking and closing effects, It does not conform to the actual situation and other problems, so as to achieve the effect of improving the simulation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

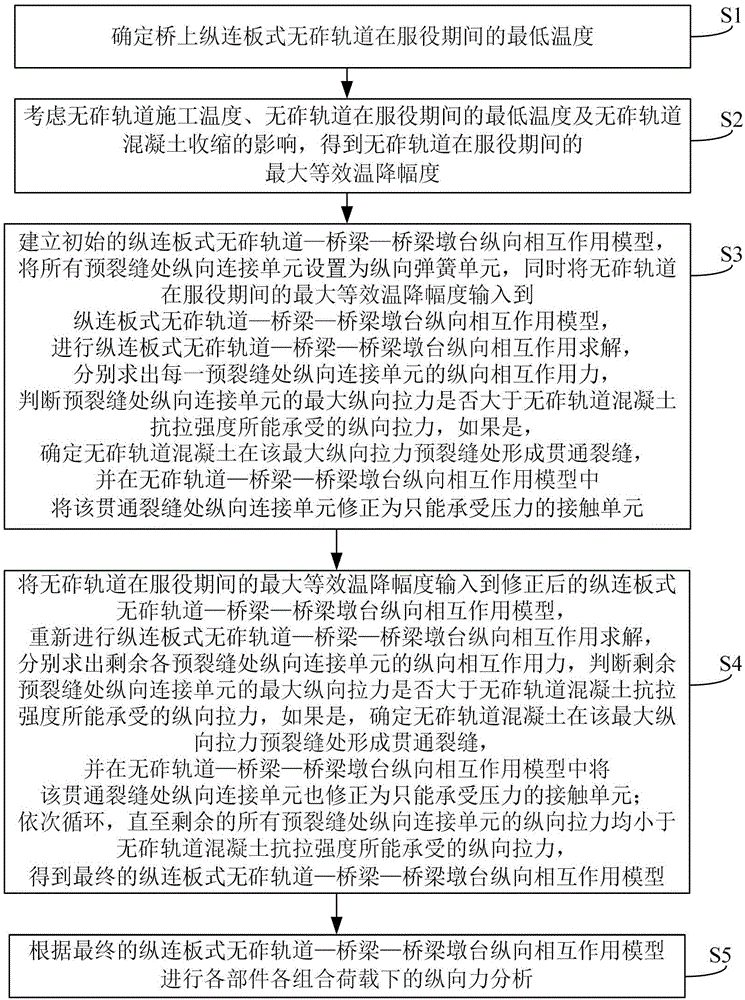

[0032] The embodiment of the present invention firstly discloses a method for analyzing the longitudinal interaction between the longitudinally connected slab ballastless track and the bridge, such as figure 1 shown, including:

[0033] Step S1, determining the minimum temperature of the longitudinally connected slab ballastless track on the bridge during service. The concrete realization of this step can be realized through following (1)-(5):

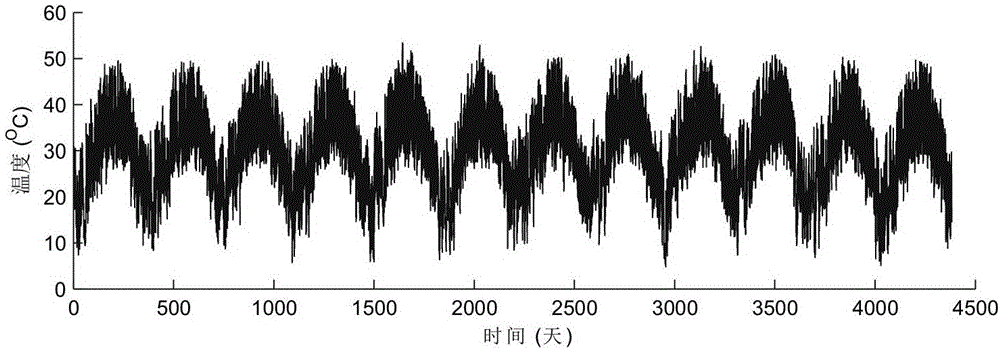

[0034] (1) Download the relevant meteorological data of a regional meteorological bureau from the website of the meteorological bureau, including year, month, day, average wind speed, average temperature, sunshine hours, daily minimum temperature, daily maximum temperature, total daily total radiation, etc.

[0035] (2) Drawing on the research results of the temperature field of engineering structures at home and abroad, a calculation model for the temperature field of the longitudinal slab ballastless track on the bridge is established...

Embodiment 2

[0050] In order to facilitate those skilled in the art to fully understand the technical solutions of the present invention, this embodiment further describes the foregoing embodiment 1 in detail in combination with specific scenarios.

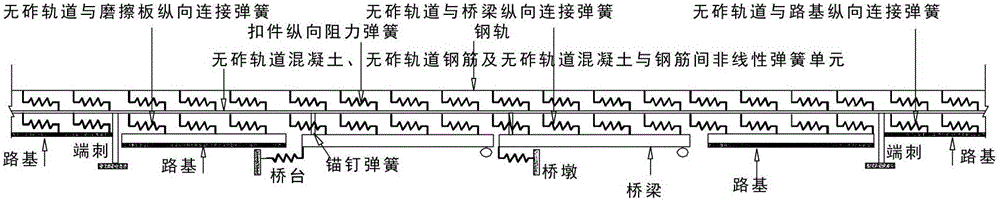

[0051] In this embodiment, the rolling stock adopts the CRH3 high-speed train widely used on high-speed railways in my country; the track slab is a standard CRTS II track slab widely used on high-speed railways, and its concrete label is C55. The track slab is 2.55 meters wide and 0.2 meters thick. The base plate concrete is high-performance concrete for high-speed railways, the concrete grade is C30, the width is 2.95 meters, and the thickness is 0.2 meters; the longitudinal main reinforcement of the ballastless track reinforcement is 6 HRB500 fine-rolled threaded steel bars with a diameter of 20mm in the track slab and There are 58 HRB500 threaded steel bars with a diameter of 16mm in the base plate; the bridge is a 32m double-line standard box...

Embodiment 3

[0079] Corresponding to the above-mentioned embodiments 1 and 2, this embodiment discloses a longitudinal interaction analysis system between a longitudinally connected slab ballastless track and a bridge, including:

[0080] The first processing unit is used to determine the minimum temperature of the longitudinal connecting slab ballastless track on the bridge during service;

[0081] The second processing unit is used to consider the influence of the construction temperature of the ballastless track, the minimum temperature of the ballastless track during service and the shrinkage of the ballastless track concrete, and obtain the maximum equivalent temperature drop of the ballastless track during service;

[0082] The third processing unit is used to establish the initial longitudinal interaction model of the ballastless track-bridge-bridge abutment of the longitudinally connected slab. The longitudinal connection units at all pre-cracks are set as longitudinal spring units,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com