Heat energy power system comprehensively utilizing waste heat of acting pump

A power system and work technology, applied in the field of energy utilization equipment, can solve the problems of unstable medium pressure, low mechanical energy conversion efficiency, and easy deterioration of working fluid, so as to improve gasification efficiency and condensation efficiency, improve thermal energy conversion efficiency, avoid Incomplete condensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

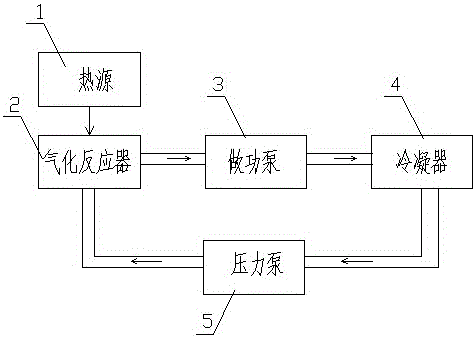

[0097] Embodiment one (such as figure 1 Shown): a thermal power system that comprehensively utilizes the waste heat of the work pump, including heat source 1, gasification reactor 2, work pump 3, condenser 4, pressure pump 5 and circulation pipeline 6, gasification reactor 2, work pump 3. The condenser 4 and the pressure pump 5 realize circulation and communication through the circulation pipe 6, and the gasification reactor 2 is in contact with the heat source 1;

[0098] As a specific description of the above implementation process, the heat source 1 adopts medium-high temperature gas.

[0099] As a specific description of the above implementation process, the gasification reactor 2 includes a layer of cavity 21; the cavity 21 is elliptical.

[0100] As a specific description of the above implementation process, the working pump 3 is an impeller working pump.

[0101] As a specific description of the above implementation process, the condenser 4 is an air-cooled condenser....

Embodiment 2

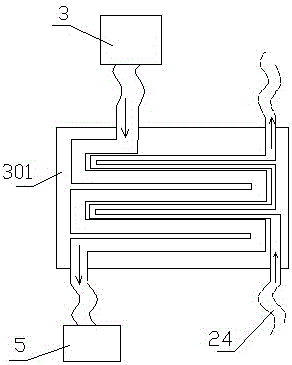

[0105] Embodiment two (such as figure 2 shown): The difference from Example 1 is that: the front end of the gasification reactor 2 is also provided with a preheating chamber 24, and the outlet of the working pump 3 is provided with a precondensation chamber 301, and the preheating The chamber 24 is in parallel contact with the pre-condensation chamber 301; the preheating chamber 24 is in spiral contact with the pre-condensation chamber 301; 1. A flow rate display meter 241 is installed at both ends of the outlet; a flow control valve 242 is also arranged in the preheating chamber 24; the flow-limiting booster valve 242 is an electronically controlled flow control valve.

[0106] With the above structure, since the working medium in the preheating chamber 24 needs to absorb heat, and the working medium in the precondensing chamber 301 needs to discharge heat, this structure recycles the heat of the working medium in the circulation pipeline to a greater extent, increasing the ...

Embodiment 3

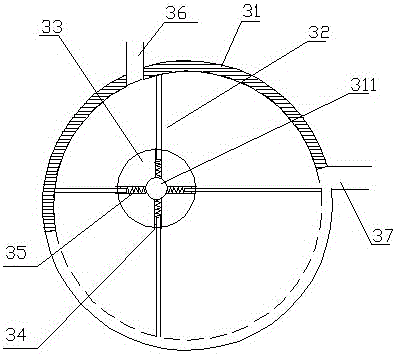

[0108] Embodiment three (such as image 3 shown): The difference from Embodiment 1 is that the working pump 3 includes a circular chamber 31, eccentric blades 32 and a grooved runner 33, and the grooved runner 33 is eccentrically installed on the eccentric shaft 311 of the circular chamber 31 Inside, the side of the grooved runner 33 is provided with a card slot 34, the eccentric blade 32 is installed in the card slot 34 through a spring leaf 35, and the sides of the circular cavity 31 are respectively provided with an air inlet 36 and an air outlet 37, and the air inlet The spacing angle between mouth 36 and air outlet 37 is greater than the spacing angle between adjacent two eccentric blades 32; The pitch angle between two adjacent eccentric blades 32; the eccentric blades 32 of the working pump 3 include four pieces.

[0109] Adopt above-mentioned structure, form isolated chamber between adjacent eccentric blades 32, and what communicate with air inlet 36 is expansion cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com