Air-drive oil extraction method including injecting air into an oil reservoir and increasing the temperature through oxygen-rich oil cracking and electromagnetic wave

A technology of air injection and electromagnetic wave, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problem of not effectively increasing the energy of oxidative cracking of oil reservoirs, prevent safety accidents, speed up oil production, Guaranteed effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

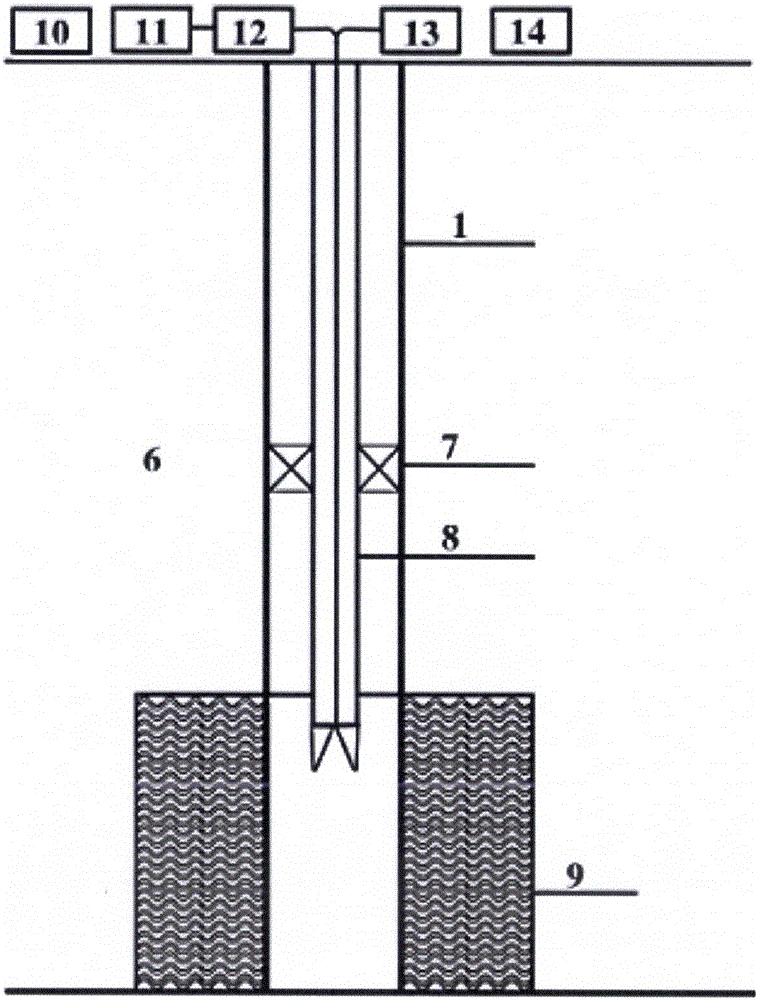

[0032] The present invention provides a method of injecting air into the oil reservoir, cracking oxygen-enriched oil and increasing the temperature by electromagnetic wave and air flooding. The location of the gas injection well is the original water injection well for secondary oil recovery. The specific implementation process is as follows:

[0033] Step 1. Complete the gas injection well and perform re-perforation. The perforation position is selected to be 2 meters in the lower part of the reservoir and 2.5 meters in the middle and upper parts. 102 gun series and 127 perforating bullets are used to penetrate the cement plugging layer and the perforation density Choose 20 holes / m;

[0034] Step 2. Inject a combustion aid (9) into the oil layer, i.e. 1 ton of ammonium nitrate and potassium chloride mixture with a mass ratio of 1:2, then inject 15,000 standard square meters of air, and then inject 0.5 tons of oxalic acid;

[0035] Step 3. Use the nitrogen separator (10) to de...

Embodiment 2

[0038] The present invention provides a method of injecting air into the oil reservoir, cracking oxygen-enriched oil and increasing the temperature by electromagnetic wave and air flooding. The location of the gas injection well is the original water injection well for secondary oil recovery. The specific implementation process is as follows:

[0039] Step 1. Complete the gas injection well and perform re-perforation. The perforation position is selected as 3 meters in the lower part of the reservoir and 2 meters in the upper part. 102 gun series and 127 perforating bullets are used to penetrate the cement sealing layer and the perforation density is selected. 25 holes / m;

[0040] Step 2. Inject a combustion aid (9) into the oil layer, i.e. 1.5 tons of ammonium nitrate and potassium chloride mixture with a mass ratio of 1:3, then inject 20,000 square meters of air, and then inject 1 ton of oxalic acid;

[0041] Step 3. Use a nitrogen separator to denitrify the air to generate ...

Embodiment 3

[0044] The present invention provides a method of injecting air into the oil reservoir, cracking oxygen-enriched oil and increasing the temperature by electromagnetic wave and air flooding. The location of the gas injection well is the original water injection well for secondary oil recovery. The specific implementation process is as follows:

[0045] Step 1. Complete the gas injection well and perform re-perforation. The perforation position is selected as 5 meters in the middle and lower part of the reservoir. 102 gun series and 127 perforating bullets are used to penetrate the cement plugging layer. The perforation density is selected as 25 holes / m;

[0046] Step 2. Inject a combustion aid (9) into the oil layer, i.e. 1.6 tons of ammonium nitrate and potassium chloride mixture with a mass ratio of 1:2, then inject 25,000 standard square meters of air, and then inject 0.8 tons of oxalic acid;

[0047] Step 3. Use a nitrogen separator to denitrify the air to generate oxygen-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com